Epoxidized natural rubber coated modified white carbon black and preparation method thereof and rubber material

A technology of natural rubber and rubber materials, applied in the field of surface modification of silica, can solve the problems of low tensile stress, low reactivity, large permanent deformation, etc., and achieves improved tensile strength, simple preparation method, and permanent deformation rate reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of epoxidized natural rubber coated modified white carbon black, comprising the following steps:

[0023] (1) provide the dispersion liquid of white carbon black, described dispersion liquid is mixed with epoxidized natural rubber, obtains mixed material;

[0024] (2) shearing the mixed material obtained in the step (1) to obtain a mixed slurry;

[0025] (3) performing solid-liquid separation on the mixed slurry described in step (2), to obtain a white carbon black precursor coated with epoxidized natural rubber;

[0026] (4) heat-treating the white carbon black precursor obtained in step (3) to obtain epoxidized natural rubber-coated modified white carbon black.

[0027] The present invention firstly provides a dispersion liquid of white carbon black. In the present invention, there is no special limitation on the operation of preparing the dispersion, and the technical solutions for preparing the dispersion well kn...

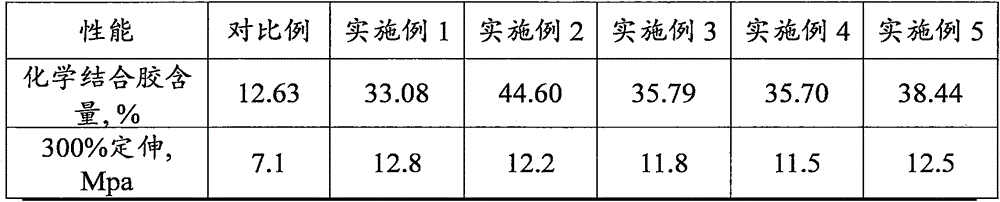

Embodiment 1

[0042] Disperse 100g of white carbon black powder in 400g of water, after ultrasonic crushing and uniform dispersion, add 50g of epoxidized natural rubber emulsion with dry rubber content of 20wt% and epoxidation degree of 40%, and disperse homogeneously under high shear Mix in the machine and process at 10000rpm for 0.5h; settle and separate the obtained mixed slurry in a centrifuge at 8000rpm, dry at 70°C for 12h, pulverize with a pulverizer, and treat at 180°C for 2h under vacuum. Obtain epoxidized natural rubber-coated modified white carbon black; carry out moisture absorption treatment under 80% air humidity, make the water content of white carbon black reach 6%; According to the formula listed in Table 1, mix with natural rubber and vulcanize to obtain rubber.

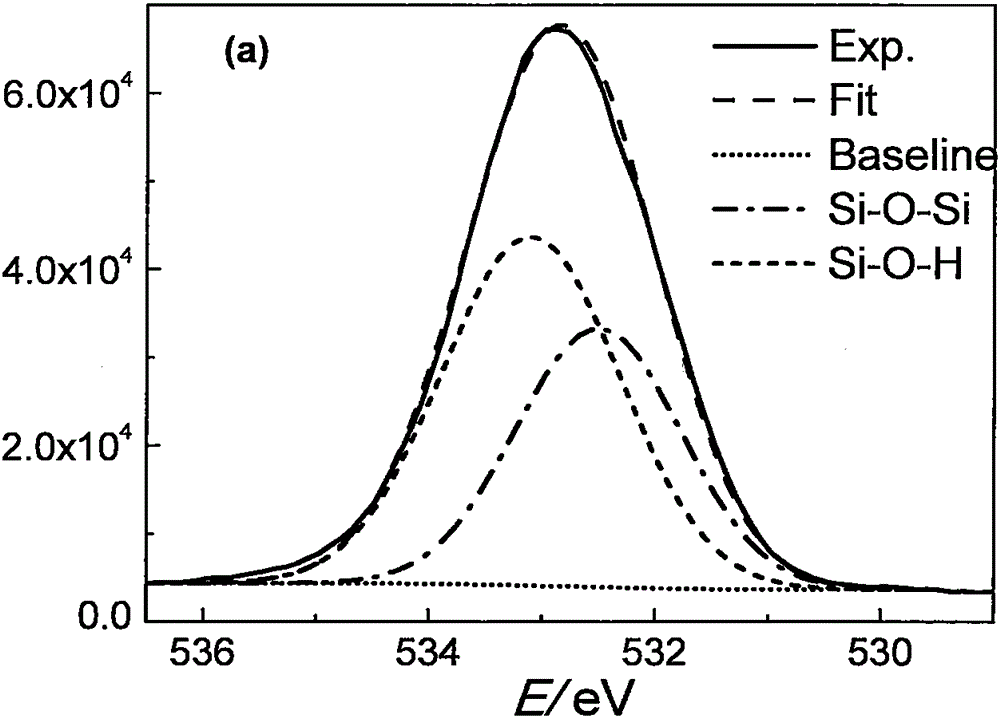

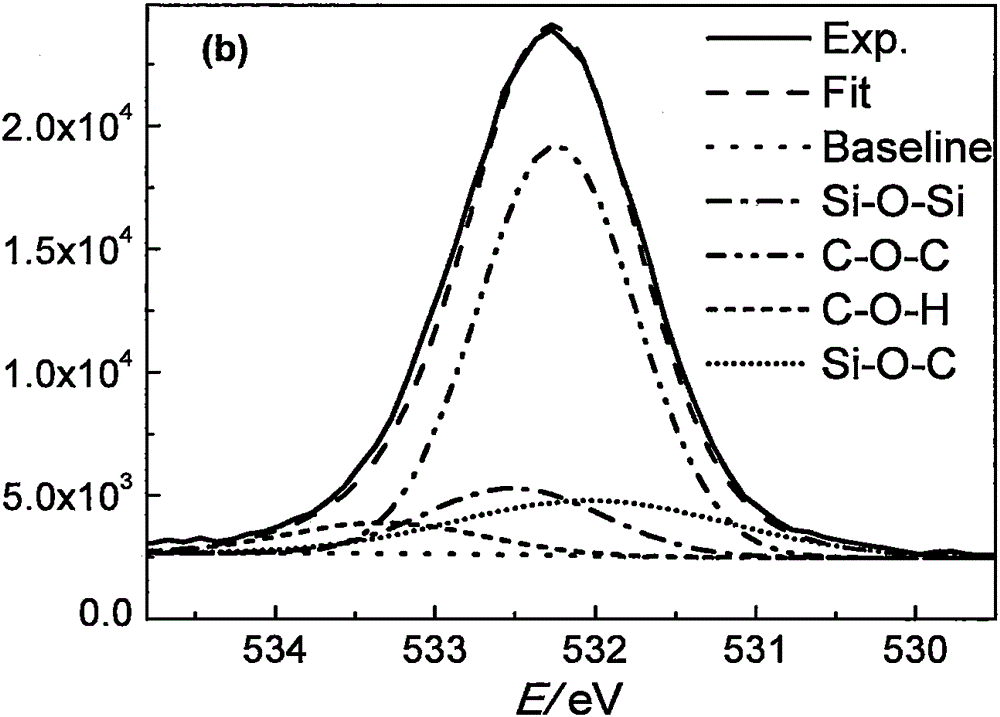

[0043] The epoxidized natural rubber-coated modified silica obtained in this example was subjected to X-ray photoelectron spectroscopy characterization test, and the results are shown in FIG. 2 . It can be seen ...

Embodiment 2

[0045] Directly take 500g dry matter content and be 20wt% white carbon black slurry, after high-speed shearing crushing, add 5gN-(β-aminoethyl-γ-aminopropyl) methyldimethoxysilane under mechanical stirring, react After 1h, add 60g of epoxidized natural rubber emulsion with a dry rubber content of 25wt% and an epoxidation degree of 25%, and process it twice under a working pressure of 200Mpa in a high-pressure homogeneous disperser; spray the obtained mixed slurry Drying, the inlet temperature of the spray drying device is 200 °C, and the outlet temperature is 100 °C; the obtained silica precursor is treated under nitrogen protection at 150 °C for 5 hours to obtain epoxidized natural rubber-coated modified silica; Hygroscopic treatment was carried out at an air humidity of 80%, so that the moisture content of the silica reached 6%; the formula listed in Table 1 was mixed with natural rubber and vulcanized to obtain rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com