Method for mild and massive preparation of mineralization silk fibroin films

A silk fibroin protein, a large number of technologies, applied in medical science, prosthesis and other directions, can solve problems such as harsh preparation conditions, and achieve the effects of simple preparation process, controllable morphology, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

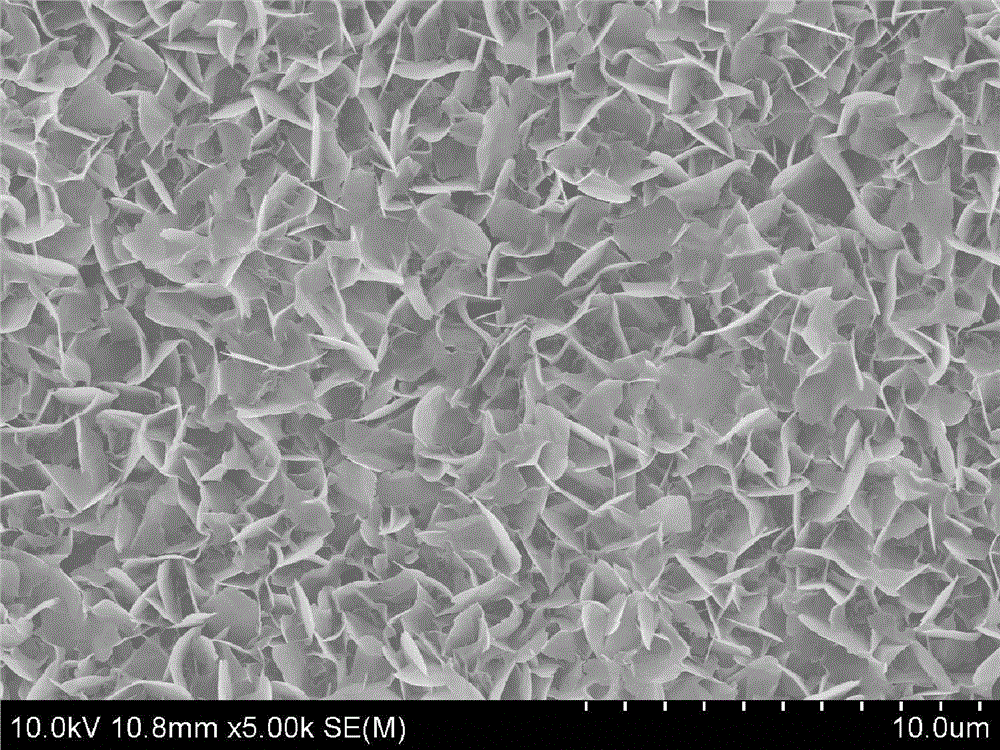

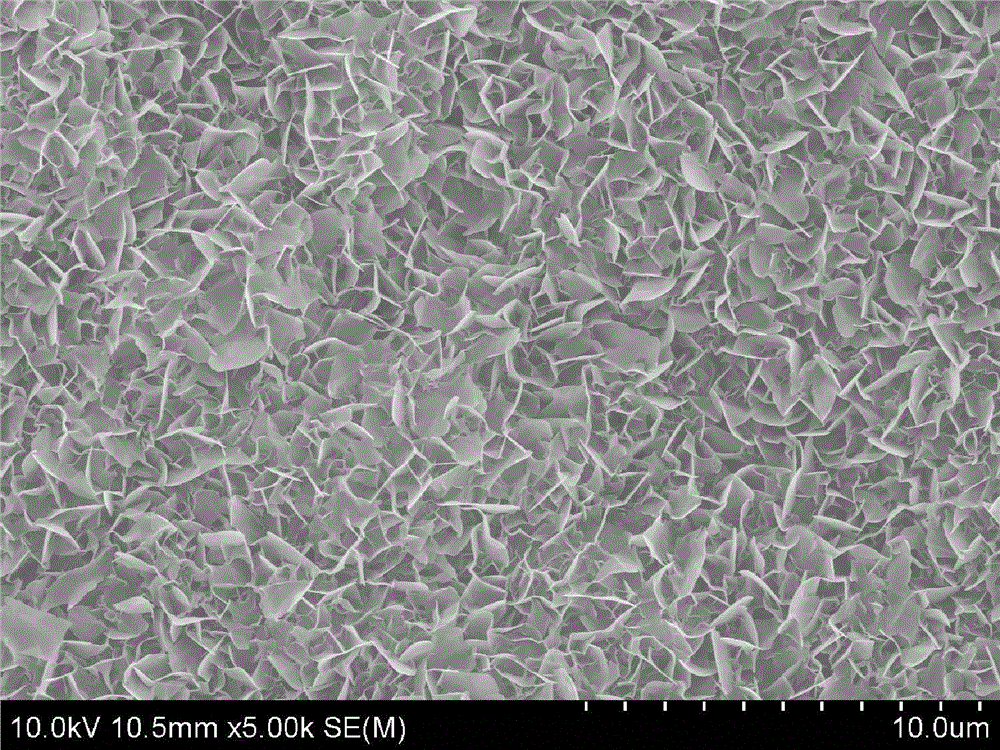

Image

Examples

Embodiment 1

[0018] (1) Preparation of silk fibroin film: a silk fibroin aqueous solution with a mass fraction of 5% was cast at 37°C to form a film;

[0019] (2) Enzyme solution pretreatment of silk fibroin film: Soak the silk fibroin film in protease XIV solution with a concentration of 1U / mL for 24 hours, place it in a shaker at 37°C, and control the speed at 100 rpm. Then take out and wash with phosphate buffer solution (0.01mol / L PBS), and dry at room temperature;

[0020] (3) Phosphate deposition: Soak the silk fibroin film pretreated by protease in PBS solution with a phosphate ion concentration of 0.1mol / L, then place it at 37°C for static incubation, take it out after 3 days, wash it with distilled water, and keep it at room temperature Dried to obtain a phosphate-mineralized silk fibroin film.

[0021] (4) Calcium salt deposition: immerse the phosphate-mineralized silk fibroin film in a calcium chloride or calcium nitrate solution with a concentration of 0.2 mol / L for 24 hours t...

Embodiment 2

[0023] (1) Preparation of silk fibroin film: a silk fibroin aqueous solution with a mass fraction of 15% was cast at 60°C to form a film;

[0024] (2) Enzyme solution pretreatment of silk fibroin film: Soak the silk fibroin film in protease XIV solution with a concentration of 2U / mL for 24 hours, place it in a shaker at 37°C, and control the speed at 100 rpm. Then take out and wash with phosphate buffer solution (0.01mol / L PBS), and dry at room temperature;

[0025] (3) Phosphate deposition: Soak the silk fibroin film pretreated by protease in PBS solution with a phosphate ion concentration of 0.1mol / L, then place it at 37°C for static incubation, take it out after 3 days, wash it with distilled water, and keep it at room temperature Dried to obtain a phosphate-mineralized silk fibroin film.

[0026] (4) Calcium salt deposition: immerse the phosphate-mineralized silk fibroin film in a calcium chloride or calcium nitrate solution with a concentration of 0.2 mol / L for 24 hours ...

Embodiment 3

[0028] (1) Preparation of silk fibroin film: a silk fibroin aqueous solution with a mass fraction of 30% was cast at 37°C to form a film;

[0029] (2) Enzyme solution pretreatment of silk fibroin film: Soak the silk fibroin film in protease XIV solution with a concentration of 6U / mL for 2 hours, place it in a shaker at 37°C, and control the speed at 200 rpm. Then take out and wash with phosphate buffer solution (0.01mol / L PBS), and dry at room temperature;

[0030] (3) Phosphate deposition: Soak the silk fibroin film pretreated by protease in PBS solution with a phosphate ion concentration of 0.05mol / L, then place it at 37°C for static incubation, take it out after 3 days, wash it with distilled water, and keep it at room temperature Dried to obtain a phosphate-mineralized silk fibroin film.

[0031] (4) Calcium salt deposition: immerse the phosphate-mineralized silk fibroin film in a calcium chloride or calcium nitrate solution with a concentration of 0.2 mol / L for 24 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com