Method for producing propylene epoxide by trickle bed reactor

A technology of propylene oxide and reactor, which is applied in the field of propylene oxide production, can solve the problems of high selectivity, inability to meet environmental protection, environmental pollution, etc. at the same time, and achieve high selectivity, high utilization rate of raw materials, and good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

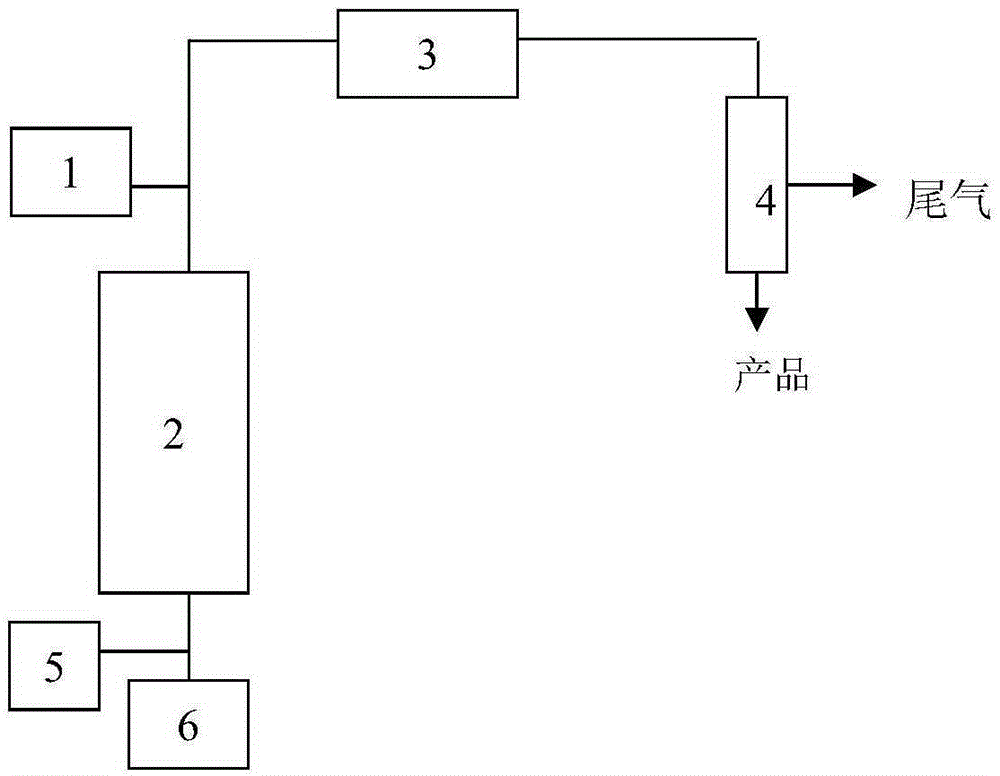

[0025] Such as figure 1 As shown, under the conditions of 55°C and 0.1 MPa, the raw material propylene flows out from the raw material gas storage tank 5 and enters from the lower end of the trickle bed reactor 2, and the mixed liquid of solvent alcohol and hydrogen peroxide flows out from the mixed liquid storage tank 1, and flows out from the trickle bed reactor 2. The upper end of the bed reactor 2 is passed into, and the inside of the trickle bed reactor 2 is coated with Au / TiO 2 -SiO 2 Catalyst packing, with multi-layer flaps inside, the filler fills the space between the flaps and the inner wall of the trickle bed reactor, propylene and hydrogen peroxide in Au / TiO 2 -SiO 2 Reaction in the catalyst bed, the reaction gas space velocity is 200h -1 , the reaction product is successively subjected to low-temperature condensation in condenser 3 (the temperature of low-temperature condensation is 1° C.), and gas-liquid separator 4 separates to obtain product propylene oxide,...

Embodiment 2

[0027] Such as figure 1 As shown, under the conditions of 35°C and 0.3 MPa, the raw material propylene flows out from the raw material gas storage tank 5, and passes into the lower end of the trickle bed reactor 2, and the mixed solution of solvent alcohol and hydrogen peroxide flows out from the mixed liquid storage 1, and flows out from the trickle The upper end of the bed reactor 2 is passed into, and the inside of the trickle bed reactor 2 is coated with Ag / TiO 2 -SiO 2 Catalyst packing, with multi-layer folded plates inside, the filler fills the space between the folded plates and the inner wall of the trickle bed reactor, propylene and hydrogen peroxide in Ag / TiO 2 -SiO 2 Reaction in the catalyst bed, the reaction gas space velocity is 200h -1 , the reaction product is successively subjected to low-temperature condensation in condenser 3 (the temperature of low-temperature condensation is 5° C.), and gas-liquid separator 4 separates to obtain product propylene oxide, ...

Embodiment 3

[0029] Such as figure 1 As shown, under the conditions of 55°C and 0.01MPa, the raw material propylene flows out from the raw material gas storage tank 5 and enters from the lower end of the trickle bed reactor 2, and the mixed liquid of solvent alcohol and hydrogen peroxide flows out from the mixed liquid storage 1, and flows out from the trickle bed reactor 2. The upper end of the bed reactor 2 is passed into, and the inside of the trickle bed reactor 2 is coated with Ag / TiO 2 -SiO 2 Catalyst packing, with multi-layer flaps inside, the filler fills the space between the flaps and the inner wall of the trickle bed reactor, propylene and hydrogen peroxide in Pd / TiO 2 -SiO 2 Reaction in the catalyst bed, the reaction gas space velocity is 350h -1, the reaction product is successively subjected to low-temperature condensation in condenser 3 (the temperature of low-temperature condensation is 10° C.), and gas-liquid separator 4 separates to obtain product propylene oxide, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com