Preparation method and structure of aluminum foil material specially used for packaging hair dyes

A hair dye and aluminum foil technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of packaging cost, space consumption, inconvenience in carrying, etc., and achieve the effect of shrinking volume, reducing packaging cost, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

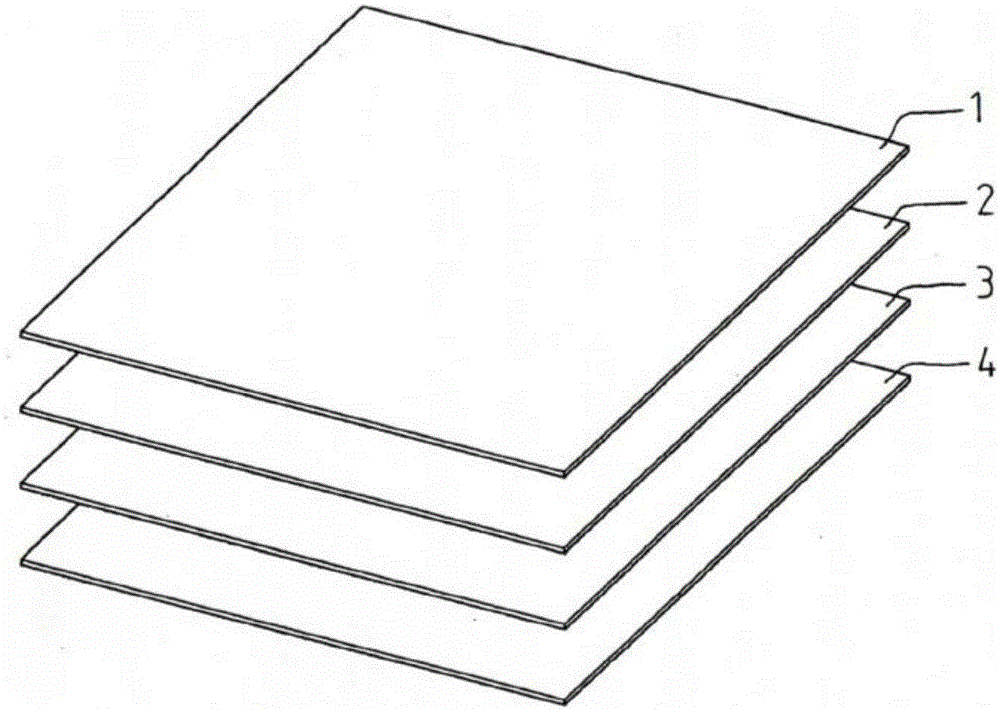

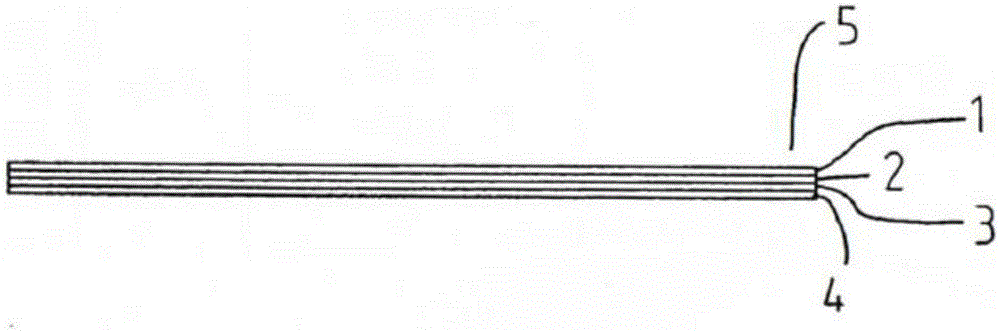

[0029] Please refer to Figures 1-9, in the embodiment of the present invention, the manufacturing method and structural composition of the present invention mainly include: from top to bottom, polyester film A1, aluminum foil 2, polyester film B3 and polypropylene film 4. Polyester film A1 and polyester film B3 have excellent elasticity and ductility, and have a certain degree of support strength; aluminum foil 2 is used to isolate light and oxygen and moisture in the air; polypropylene film 4 has heat sealing properties , so as to facilitate the sealing operation of the packaging and ensure that the contents (that is, hair dye) have no penetration or overflow.

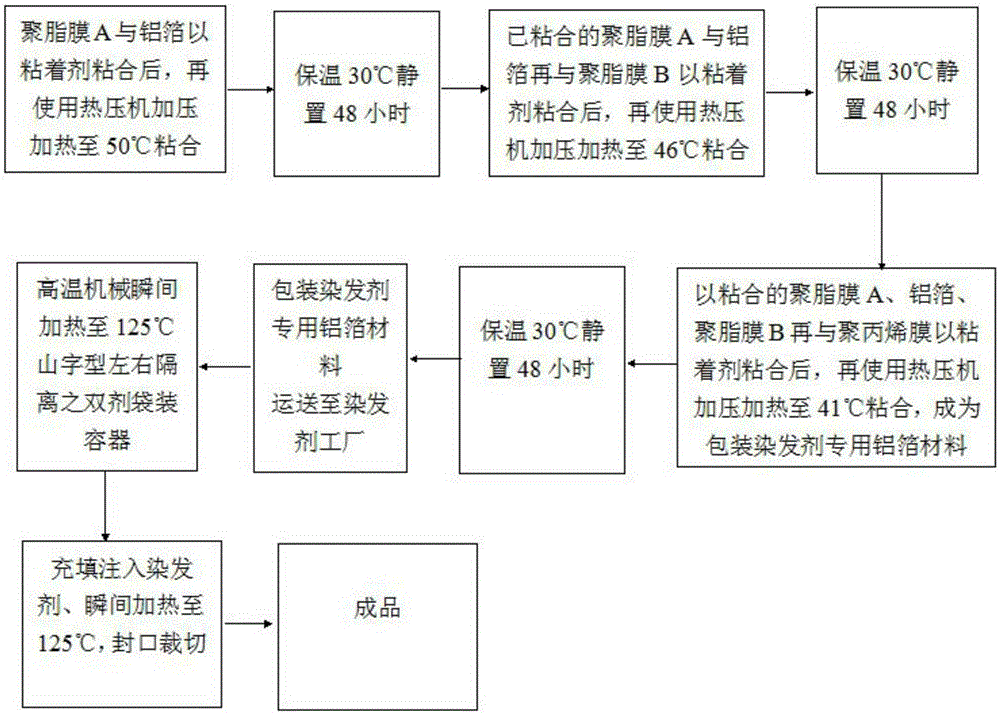

[0030] In the operation of composing the special aluminum foil material 5 for packaging hair dyes of the present invention by combining the above materials, firstly, after the polyester film A1 and the aluminum foil 2 are bonded with an adhesive, they are heated to 50°C with a hot press to make the It is glued into on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com