Waste chip cleaning type processing working table

A workbench and table body technology, which is applied in the field of machining devices, can solve the problems of inconvenient cleaning and recycling of waste materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

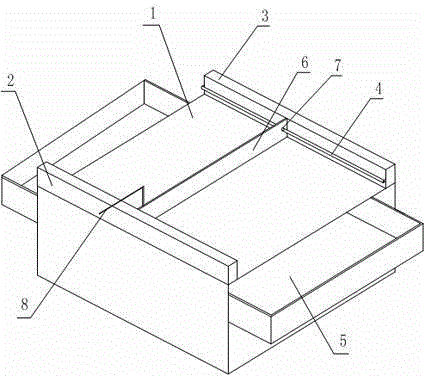

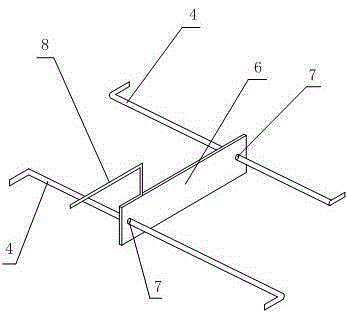

[0016] like figure 1 and figure 2 The shown waste cleaning type processing workbench includes a square table body 1, the left and right side of the table body 1 are provided with drawers 5, and the front and rear edges of the upper surface of the table body 1 are A first baffle plate 2 and a second baffle plate 3 perpendicular to the upper surface of the table body 1 are respectively provided, and the inner surfaces of the first baffle plate 2 and the second baffle plate 3 are welded with protruding connecting rods 4 A scraper 6 is arranged between the two connecting rods 4, and both sides of the scraper 6 are provided with through holes 7 through which the connecting rod 4 can pass, and the bottom edge of the scraper 6 is in contact with the The upper surface of the table body 1 is adjacent, and the push rod 8 extending to the outside of the table body 1 is fixedly connected to the scraper 6 . In this embodiment, the connecting rods 4 on the left and right sides respective...

Embodiment 2

[0018] like figure 1 and figure 2 In the waste cleaning type processing workbench shown, on the basis of Embodiment 1, the height of the scraper 6 is the same as that of the first baffle 2 and the second baffle 3, and the scraper 6 The width is the width between the first baffle plate 2 and the second baffle plate 3 . When performing parts processing in this embodiment, the scraper 6 is pushed to the edge of the table body 1, and its height is set to be consistent with the height of the first baffle plate 2 and the second baffle plate 3 , to prevent the scraper 6 from being too high to interfere with the operator's actions and affect the processing of the machine parts; and the width of the scraper 6 is set to be between the first baffle 2 and the second baffle 3 The width can push down the remaining waste materials to the maximum extent into the drawer 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com