Electron beam surface machining method realizing workpiece drag reduction and plate with anti-drag surface

A technology of surface processing and workpiece surface, applied in the field of electron beam surface processing, can solve the problem of inability to process the micro-structure of triangular grooves imitating sharkskin, and achieve the effect of reducing drag and improving the distribution of flow field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An electron beam surface processing method for realizing drag reduction of a workpiece, comprising the following steps:

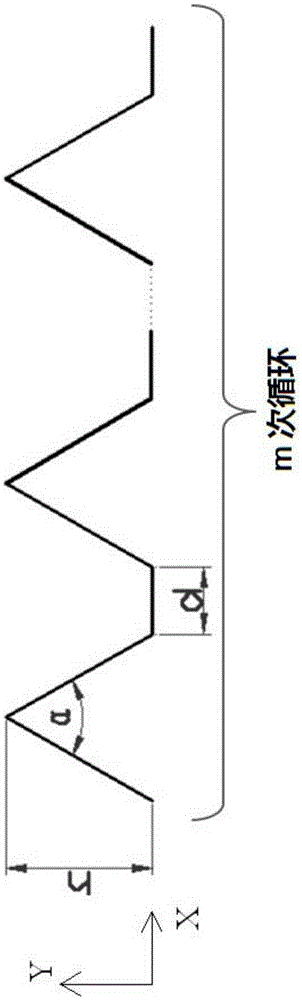

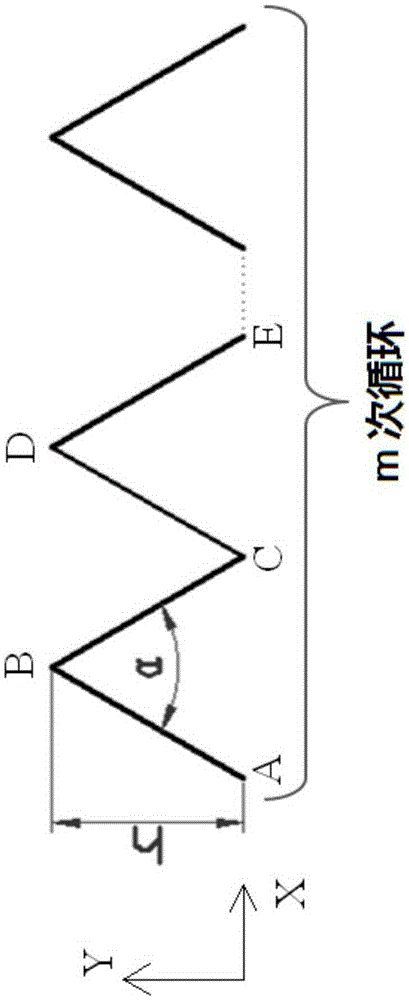

[0027] Step 1, make the electron beam scan the workpiece surface one by one along the first direction A according to the angle (ie figure 1 The track left by the electron beam scanning an angle on the surface of the workpiece is the same as the angle), until the scanning of the row of angles is completed, and the workpiece is moved along the second direction B on the surface of the workpiece while the electron beam is scanning, the first The second direction B is a direction perpendicular to the first direction A on the surface of the workpiece;

[0028] Each of the angles is composed of two sides and three endpoints formed by the intersection of the two sides. Among the three endpoints, the endpoint formed by the intersection of the two sides is the apex, and the other two endpoints are both bottom points. The angle bisectors of the two angles are ...

Embodiment 2

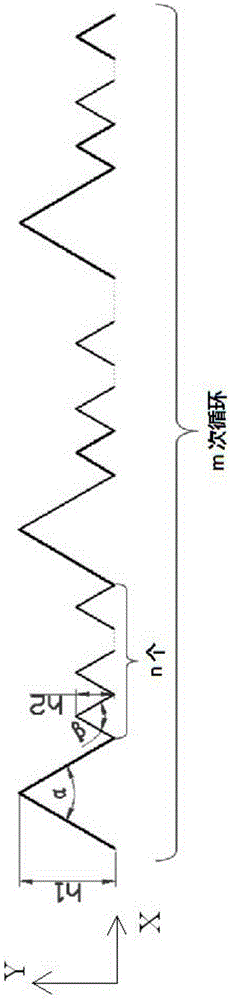

[0053] This embodiment is an alternative to Embodiment 1. The electron beam surface processing method for achieving drag reduction of workpieces described in this embodiment includes the following steps:

[0054] Step 1. Make the electron beam scan the surface of the workpiece along the first direction A according to the angles one by one, until the scanning of the row of angles is completed;

[0055] Each of the angles is composed of two sides and three endpoints formed by the intersection of the two sides. Among the three endpoints, the endpoint formed by the intersection of the two sides is the apex, and the other two endpoints are both bottom points. The angle bisectors of each of the angles are perpendicular to the first direction, and the order of the electron beam scanning each of the angles on the surface of the workpiece is: starting from the apex of the angle and scanning along a side of the angle to reach the side end at the bottom point of the angle, and then scan ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com