Method for carrying out superfine wall breaking and smashing on boletus

A technology of ultra-fine wall-breaking pulverization and boletus, applied in the field of medicine, can solve the problems of low powder yield, high loss rate of adenosine, long pulverization time, etc., and achieves high powder yield, small average particle size of powder, The effect of short processing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

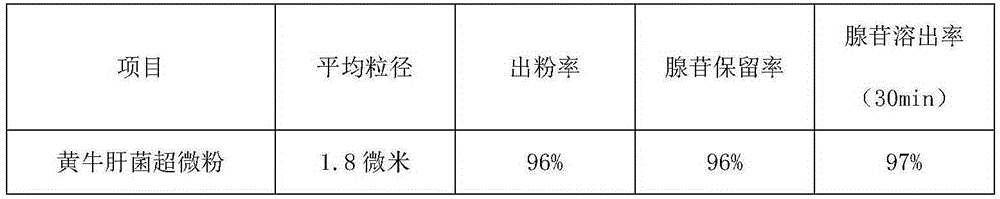

[0016] Crush 3kg of yellow boletus and pass through a 60-80 mesh sieve to obtain yellow boletus powder; mix 8g of γ-cyclodextrin and 2g of medium-chain triglyceride evenly to obtain γ-cyclodextrin-medium-chain triglyceride mixed powder ;Mix boletus powder and γ-cyclodextrin-medium chain triglyceride mixed powder evenly, and use SWFJ ultrafine pulverizer to pulverize for 1 hour, and measure the average particle size, powder extraction rate, adenosine retention rate and dissolution of the obtained powder The results are shown in Table 1.

[0017] The relevant data of the boletus superfine powder of table 1 embodiment 1

[0018]

Embodiment 2

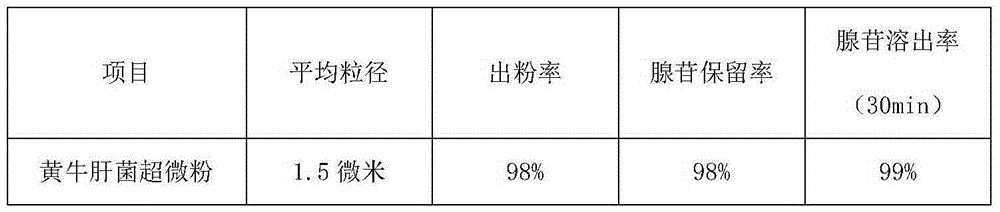

[0020] Crush 3kg of yellow boletus and pass through a 60-80 mesh sieve to obtain yellow boletus powder; mix 12g of γ-cyclodextrin and 3g of medium-chain triglycerides evenly to obtain γ-cyclodextrin-medium-chain triglycerides mixed powder ;Mix boletus powder and γ-cyclodextrin-medium chain triglyceride mixed powder evenly, and use SWFJ ultrafine pulverizer to pulverize for 1 hour, and measure the average particle size, powder extraction rate, adenosine retention rate and dissolution of the obtained powder The results are shown in Table 2.

[0021] The relevant data of the boletus superfine powder of table 2 embodiment 2

[0022]

Embodiment 3

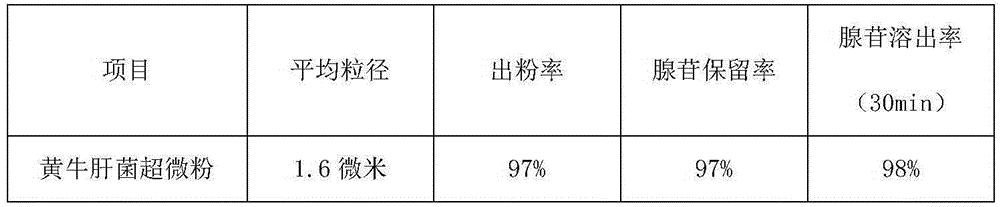

[0024] Grind 3kg of yellow boletus and pass through a 60-80 mesh sieve to obtain yellow boletus powder; mix 9.6g of γ-cyclodextrin and 2.4g of medium-chain triglycerides evenly to obtain γ-cyclodextrin-medium-chain triglycerides Mixed powder: Mix boletus powder and γ-cyclodextrin-medium chain triglyceride mixed powder evenly, and use SWFJ ultrafine pulverizer to pulverize for 1 hour, and measure the average particle size, powder yield, and adenosine retention rate of the obtained powder And dissolution rate, the results are shown in Table 3.

[0025] The relevant data of the boletus superfine powder of table 3 embodiment 3

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com