Proximity switch test device under high temperature environment

A technology of proximity switches and testing devices, which is applied in the direction of circuit breaker testing, etc., can solve the problems of high dispersion of temperature resistance of proximity switches, inability to replace sensors, lack of operational reliability, etc., and achieve the effect of easy and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

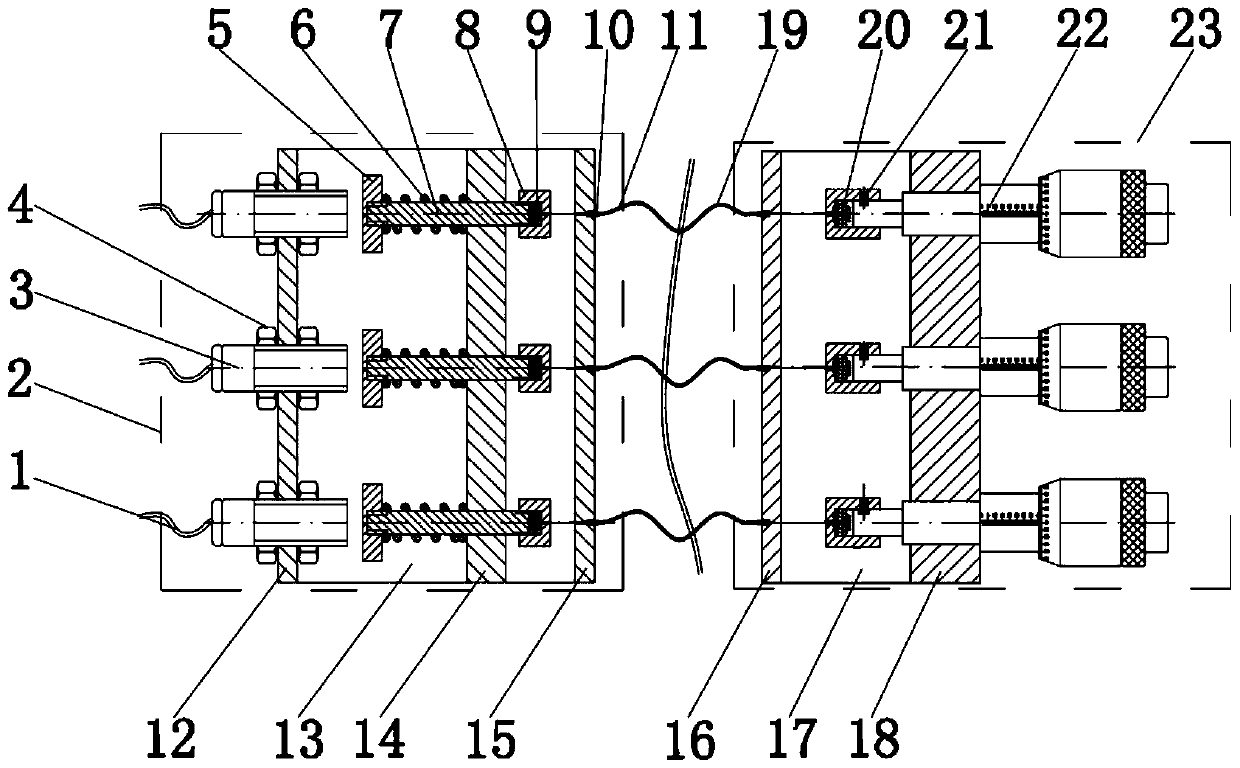

[0023] The test device of the present invention is mainly divided into two parts: a high temperature area and a normal temperature area. There are proximity switch 3, proximity switch mounting bracket 12, sensor plate moving device bracket 14, etc. inside the high temperature area, and the normal temperature area mainly includes displacement adjustment bracket 18, micrometer 22, etc. On the described proximity switch mounting bracket 12, a proximity switch 3 and an induction piece 5 that can move and rebound under tension are installed; a micrometer 22 with adjustable displacement is installed on the displacement adjustment bracket 18; the steel wire One end of the backguy 11 is connected to the induction sheet 5 on the induction sheet moving device support 14 in the high-temperature oven 2, and the other end is connected to the micrometer 22 on the displacement adjustment support 18; Or loosen the steel wire 11; on the bottom plate 13 in the high temperature zone and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com