Screw rotor without acute-angle cusp

A technology with sharp angles and sharp screws, which is applied in the direction of rotary piston pumps, rotary piston machines, and parts of pumping devices for elastic fluids, etc. It can solve the problems of large gas leakage, poor gas sealing performance, and easy wear of edges and other issues to achieve the effect of improving sealing performance and mechanical properties, improving overall performance, increasing ultimate vacuum degree and pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

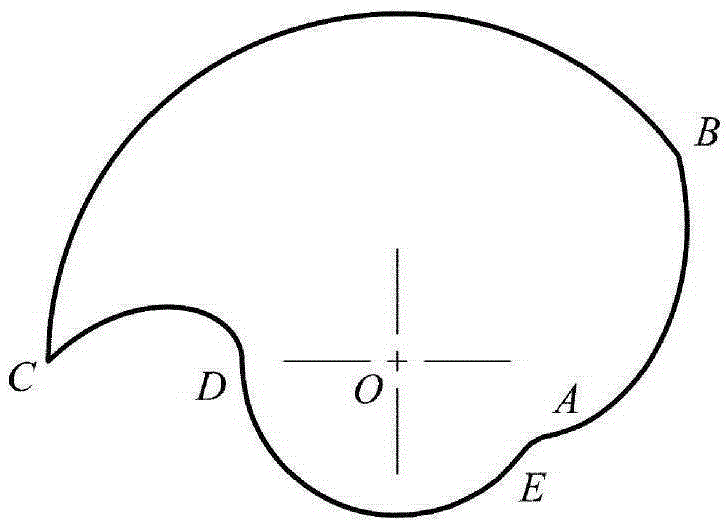

[0022] Such as figure 1 As shown, the connection point C between the addendum arc BC and the cycloid CD of the existing screw rotor end surface profile line is an acute point.

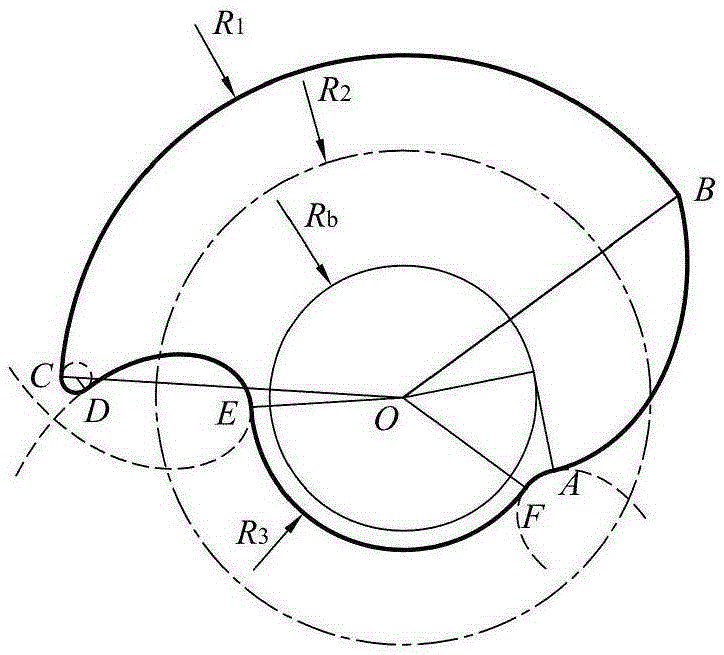

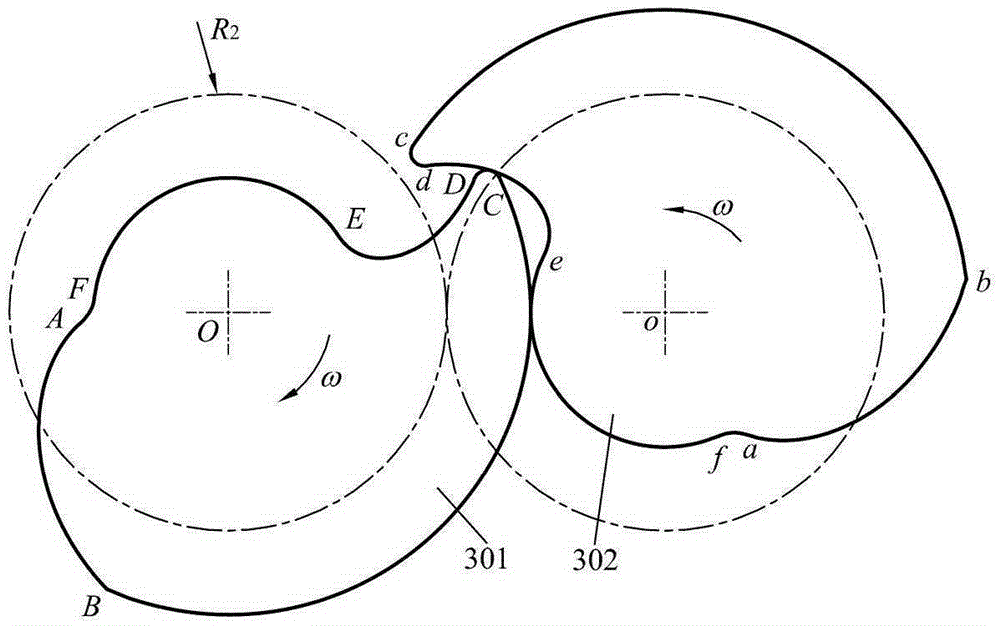

[0023] Such as figure 2 As shown, a screw rotor end surface profile line without acute angle points is composed of 6 curves, which are: circular involute AB, addendum arc BC, arc CD, cycloidal equidistant curve DE, dedendum Circular EF and cycloid FA; the equidistant curves of 1 section of circular arc CD and 1 section of cycloid DE are used to smoothly connect the addendum arc BC and the dedendum arc EF, eliminating the screw rotor end face type The sharp point in the line forms the screw rotor end surface profile line without acute angle point; the screw rotor end surface profile line is not smooth except the connection between the circular involute AB and the addendum arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com