Guide rail mechanism

A technology of guide rails and racks, applied in the field of transportation rails, can solve the problems of angle deviation, hidden dangers of assisted elevator safety, and easy deviation of gear and rack meshing transmission, so as to ensure safety, improve motion stability, and mesh accurately. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

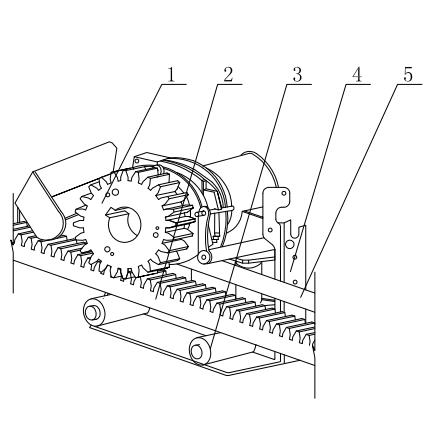

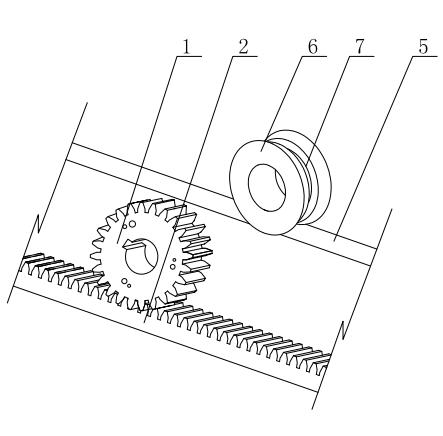

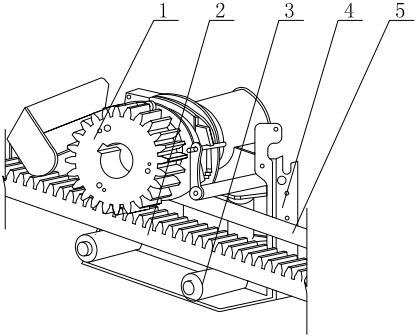

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] The rail mechanism of the present invention comprises frame 4, gear 1 and rack 2, and rack 2 is positioned at the top of a pair of rollers 3; The cooperating guide wheel 6 is coaxial with the gear 1 , and the outer peripheral surface of the guide wheel 6 is provided with a groove 7 matched with the guide rail 5 .

[0014] In actual use, the driving device drives the gear 1 to rotate, and at the same time the guide wheel 6 coaxial with the gear 1 rotates, so that the gear 1 and the rack 2 are meshed at the same time, and the guide wheel 6 runs on the guide rail 5. When the guide wheel 6 passes through the radian of the guide rail 5, it can change the angle with the gear 1 at the same time, and its meshing transmission is more accurate, which improves the transmission stability and is low in cost.

[0015] The above description is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com