Method for preparing biomass material with high heat calorific value through calcination coupling self-cross-linking of salix material

A biomass material and self-crosslinking technology, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of quality yield decline and heat value increase efficiency are not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

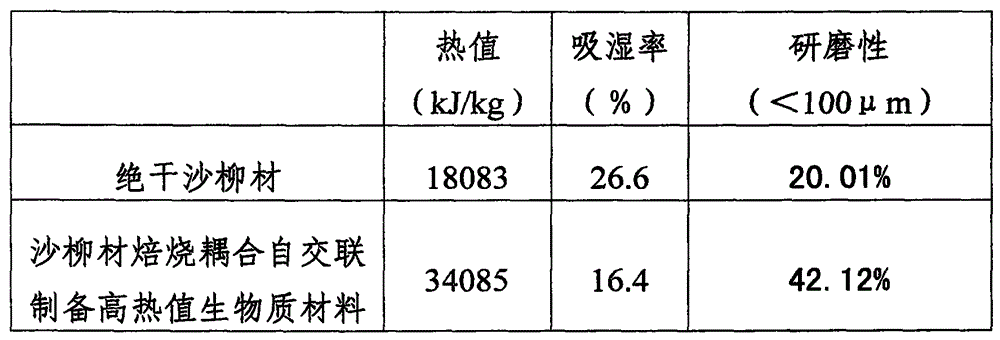

Image

Examples

Embodiment example

[0023] 500g of Salix salix wood which is naturally dried is longitudinally cut, axially rolled into fragments with a length of 1cm and an equivalent diameter of 3-5mm, and then immersed in a sodium hydroxide solution with a concentration of 10-20% for 1 hour. It was then rinsed, vacuum dried and further comminuted to 100 mesh. Disperse 50% ethanol solution according to the volume concentration of 30%, add excess formaldehyde, react at 60°C for 1.5 hours, then add excess propylene oxide to react for 1h, heat at 160°C for 2h in vacuum, and then Calcined at 260°C for 30 minutes under nitrogen (purity not less than 99%) atmosphere. Finally, it is ground to 80 mesh to obtain the high calorific value biomass energy material of Salix salix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com