Forming method of mixed-stitch composite material of three-dimensional woven prefabrication body fabric

A composite material and molding method technology, which is applied in the field of mixed-seam composite material molding, can solve problems such as low production efficiency, low viscosity, and affect the mechanical properties of composite materials, and achieve the effect of ensuring uniform glue content and reasonable resin distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

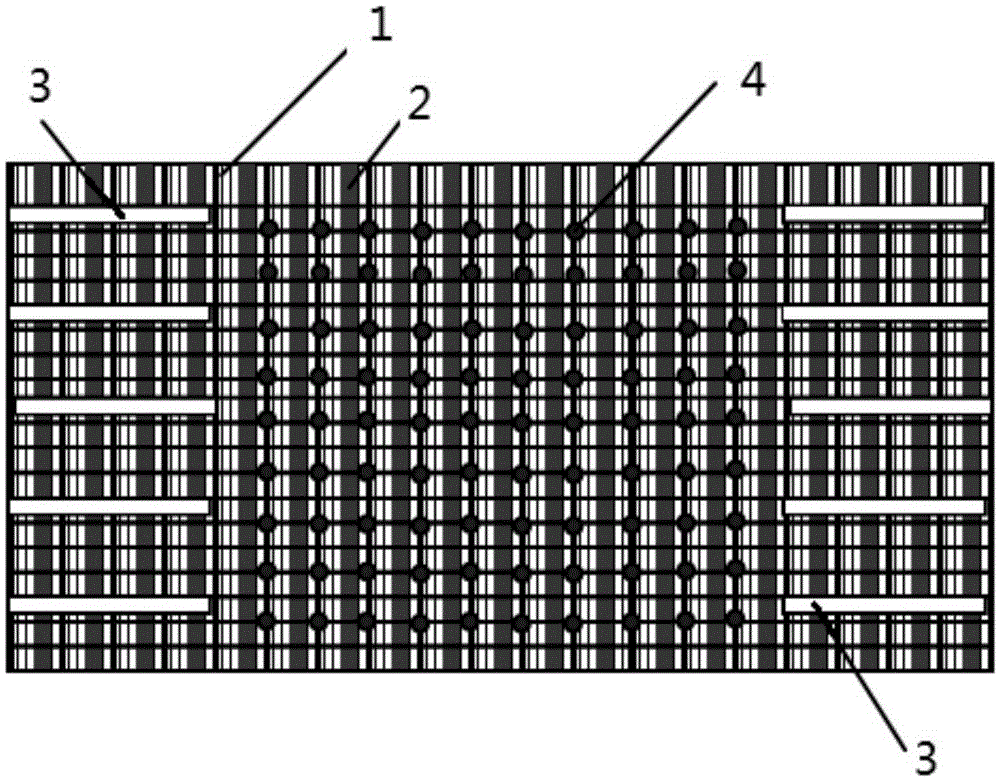

[0034] Such as figure 1 As shown, 3K carbon fiber filaments are selected as the reinforcing fiber 1 as the weaving raw material of the three-dimensional structure prefabricated body, the polyethylene film is selected as the resin film 3 and the polyethylene fiber filament is selected as the resin fiber 2 . Carbon fiber filaments and polyethylene fiber filaments are mixed and wound and assembled into the spindle of the weaving machine. The mixing ratio of polyethylene fibers accounts for 10% of the total weight of the three-dimensional composite material, and the three-dimensional four-way weaving method is used to weave a cylindrical fabric structure. The total thickness of the braiding is preset to be 20mm, among which four thickness positions of 2mm, 6mm, 10mm, and 14mm are needle-punched along the thickness plane direction of the cylinder to lay a narrow strip of polyethylene film with a thickness of 0.8mm, where the width of the narrow strip is 0.5 mm, the total weight of ...

Embodiment 2

[0037]The reinforcing fiber is 6K carbon fiber filament as the weaving raw material of the three-dimensional structure prefabricated body, the resin film is selected as the polyurethane film and the resin fiber is the polyurethane fiber filament. Carbon fiber filaments and polyurethane fiber filaments are mixed and wound and assembled into the spindle of the weaving machine. The mixing ratio of polyethylene fibers accounts for 8% of the total weight of the three-dimensional composite material, and the three-dimensional five-way weaving method is used to weave a cylindrical fabric structure. The total thickness of weaving is preset to be 10mm, among which four thickness positions of 2mm, 4mm, 6mm, and 8mm are needle-punched along the thickness plane direction of the cylinder to lay a narrow strip of polyurethane film with a thickness of 0.6mm, and the width of the narrow strip is 0.4mm , the total weight of the adhesive film accounts for 10% of the total weight of the three-dime...

Embodiment 3

[0040] The reinforcing fiber is 6K silicon carbide fiber filament as the weaving raw material of the three-dimensional structure prefabricated body, the resin film is polypropylene film and the resin fiber is polypropylene fiber filament. Silicon carbide filaments and polypropylene fiber filaments are mixed and wound and assembled into the spindle of the weaving machine. The mixing ratio of polyethylene fibers accounts for 6% of the total weight of the three-dimensional composite material, and the three-dimensional six-directional weaving method is used to weave into a square tube fabric structure. The total thickness of weaving is preset to be 15mm, among which four thickness positions of 3mm, 6mm, 9mm, and 12mm are needle-punched along the thickness plane direction of the square tube to lay a narrow strip of polypropylene film with a thickness of 0.5mm, and the width of the narrow strip is 0.3 mm, the total weight of the adhesive film accounts for 18% of the total weight of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com