Inverter resistance welding parameter error prediction quality control method

A quality control method and error prediction technology, applied in welding monitoring devices, welding power sources, etc., can solve problems such as unqualified solder joints and error parameter lag, and achieve the effect of overcoming lag problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further explanation of the inverter resistance welding welding parameter error prediction quality control method of the present invention in conjunction with the accompanying drawings, and the following examples shall not be construed as limiting the invention.

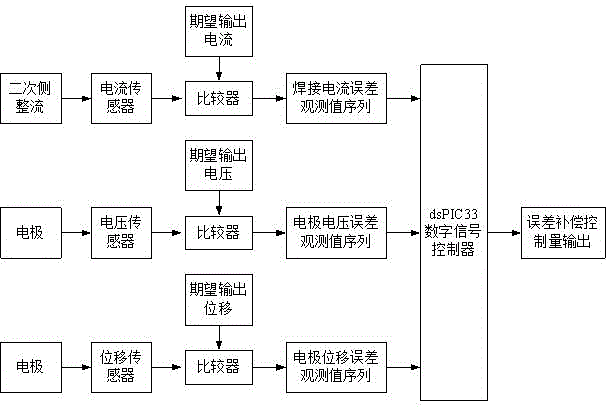

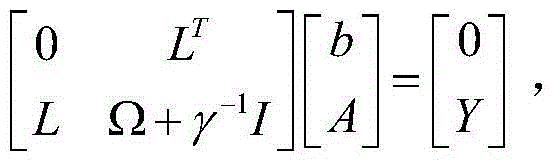

[0024] combined with figure 1 , an embodiment of a quality control method for inverter resistance welding welding parameter error prediction is as follows: the output current rectified by the secondary side is collected by a current sensor, the displacement sensor detects the electrode displacement, the voltage sensor detects the electrode voltage, and the parameters obtained by these sensors are Compared with the set expected value, the sequence of parameter error observation values is established, and a simplified prediction model including these three parameters is established, and the prediction method of least squares support vector machine is used to recursively calculate the welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com