A quasi-static uniaxial compression test method and device

A uniaxial compression, experimental device technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of small plastic compressive strain range, complex processing technology, high cost, and achieve simple manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

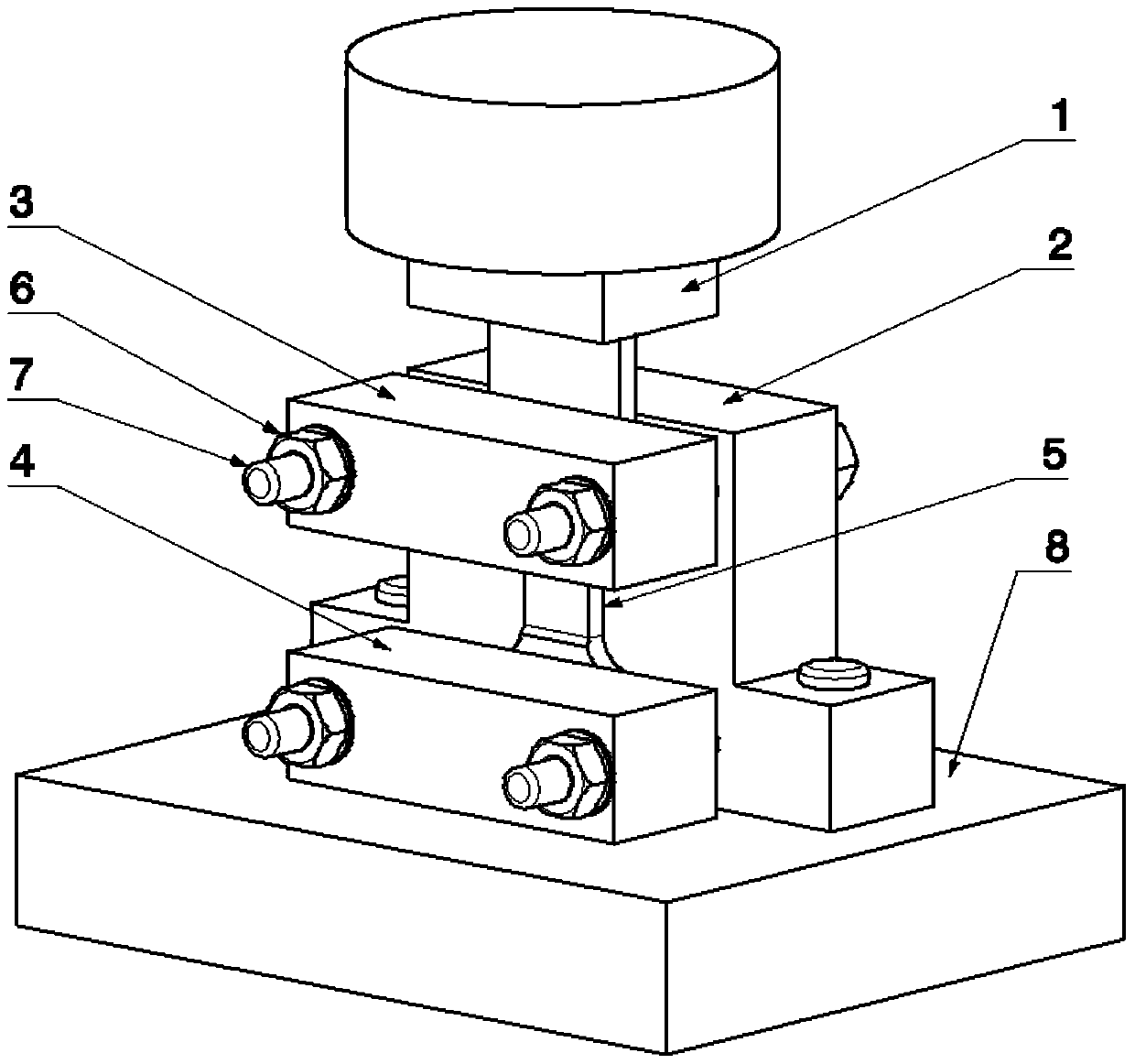

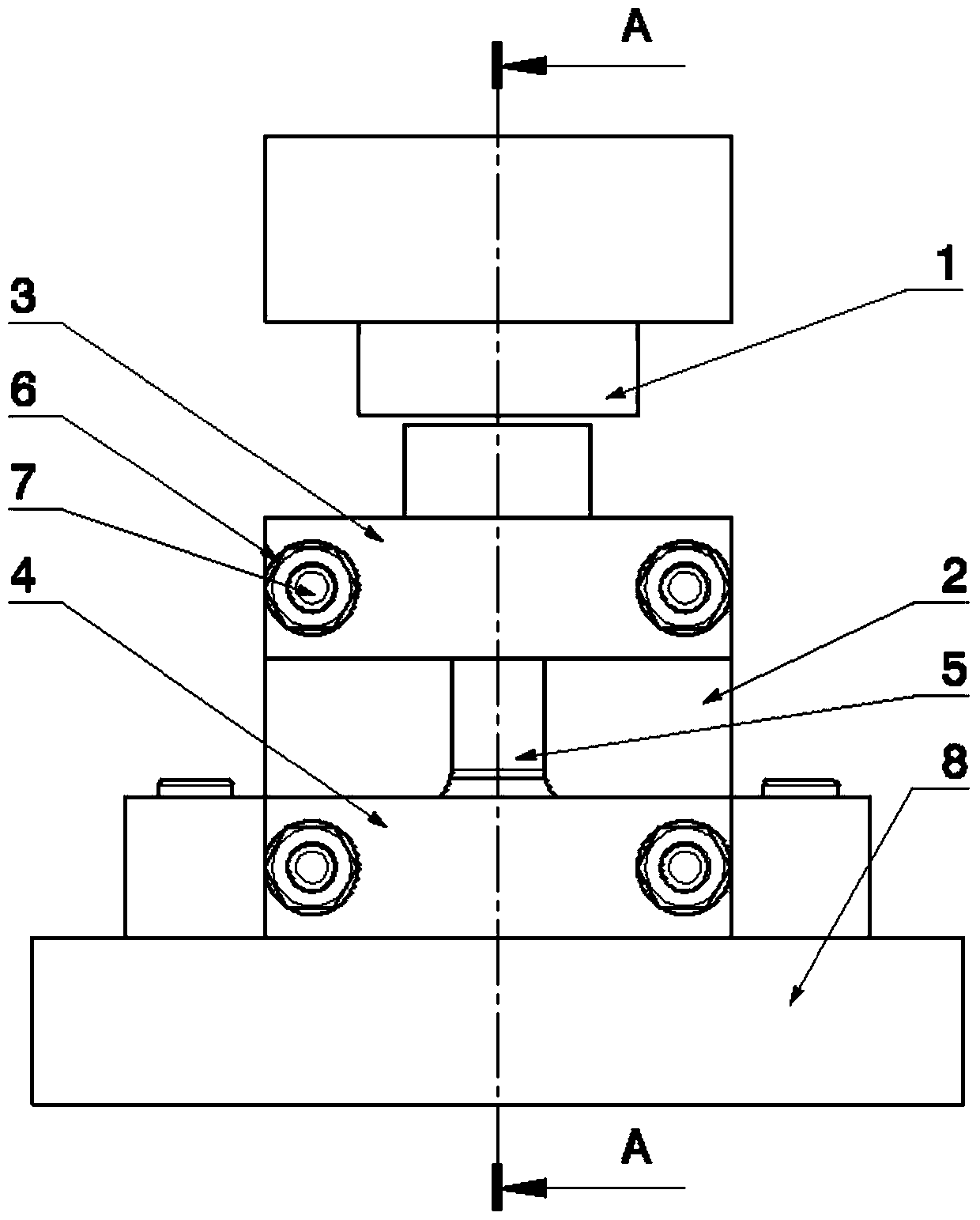

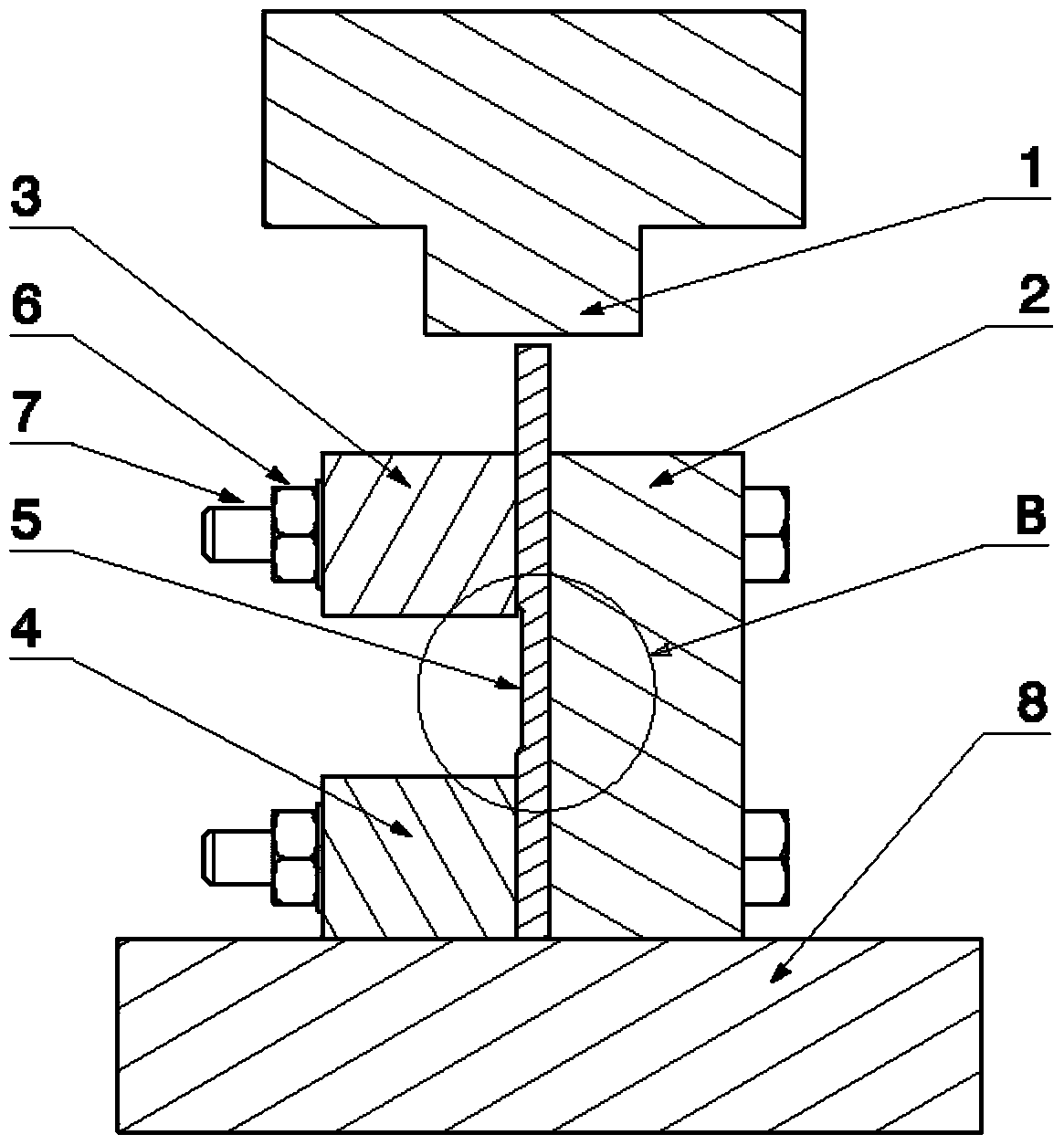

[0062] Such as Figure 1-Figure 3 As shown, a quasi-static uniaxial compression test device includes a compression fixture and a test piece 5 matched with the compression fixture. The compression fixture includes a compression platen 1 at the top, a base support plate 8 at the bottom and a The clamping part used to clamp the test piece 5 between the compression platen 1 and the base support plate 8; the clamping part includes the front upper anti-bending plate 3, the front lower anti-bending plate 4 and the back The anti-bending plate 2, the side of the test piece 5 without the groove 51 abuts against the back anti-bending plate 2, the front upper anti-bending plate 3 and the front lower anti-bending plate 4 are respectively arranged on the The upper and lower ends of the test piece 5 are fixed to the back anti-bending plate 2 through bolts 7 and nuts 6, so that the groove 51 is exposed to the outside.

[0063] Such as Figure 4-Figure 7 As shown, the test piece 5 is a plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com