Structure positioning sample preparation method of sheet

A positioning system and thin plate technology, which is applied in the preparation of test samples, etc., can solve the problems such as the inspection of thin plate tissue, and achieve the effect of flexible and accurate positioning sample preparation, strong practicability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, further illustrate the present invention by specific embodiment:

[0030] (1) Wipe and clean the surface of the thin plate 7 with alcohol to ensure that the surface is smooth and clean; if the thickness of the thin plate 7 is less than 1 mm, you can use 502 or other super glue to bond multiple samples or a piece of other steel samples with a thickness of 1 mm or more. In order to increase the inlay depth and avoid the sample falling off due to the thinness of the sample during the grinding process.

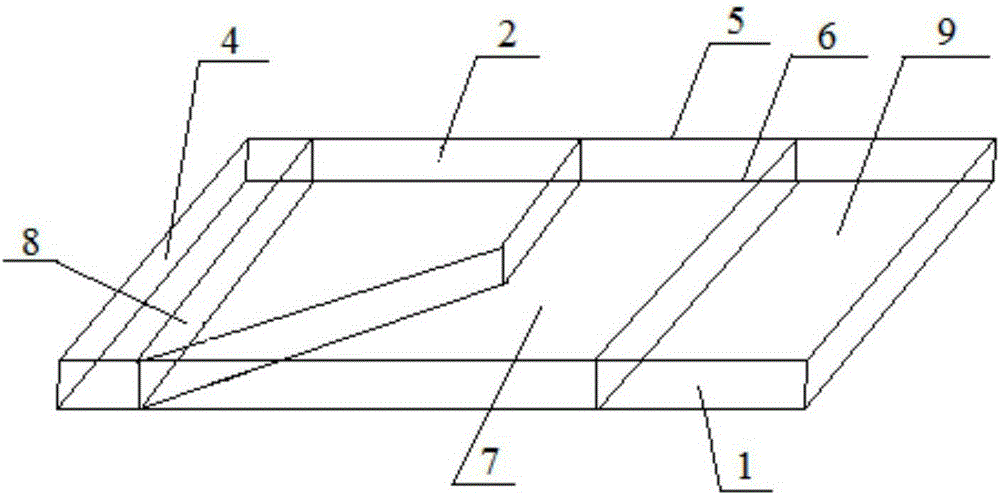

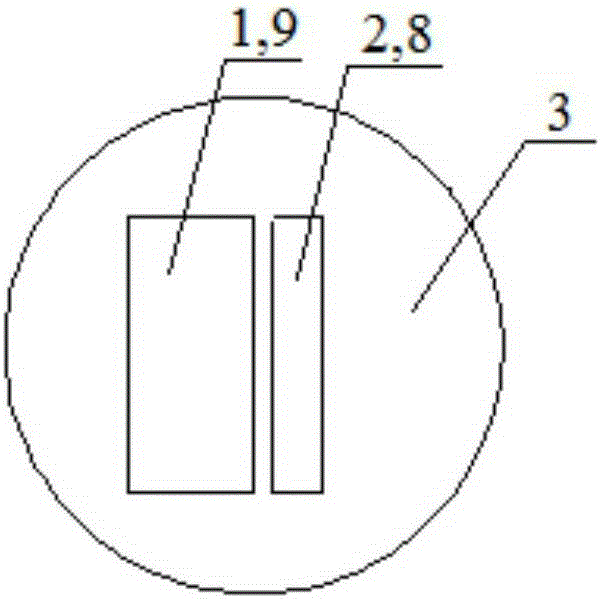

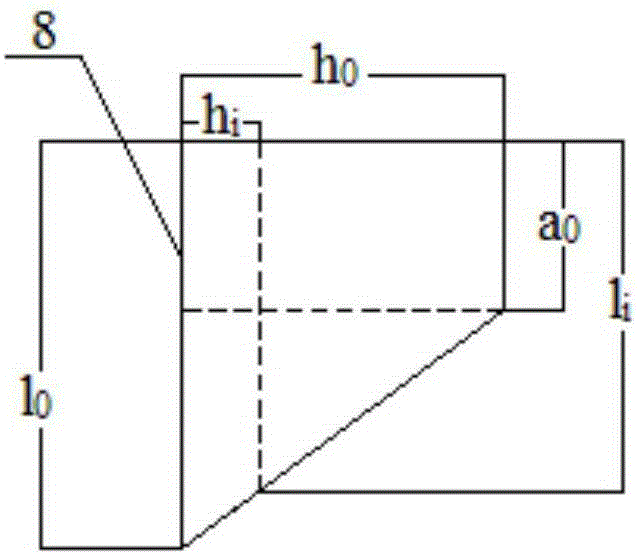

[0031] Such as figure 1 As shown, along the direction of the thickness surface 4 of the thin plate, the upper surface 5 and the lower surface 6 of the thin plate 7 are perpendicular to the plate surface sample 1 and the cross-section sample 2. Wherein the surface of the plate surface sample 1, that is, the surface of the plate sample plate, is a rectangle; the cross-section sample thickness surface 8 of the cross-section samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com