Graphene pressure sensor, manufacturing method thereof and purpose thereof

A pressure sensor and graphene technology, applied in the field of graphene pressure sensor and its preparation and use, can solve the problems that graphene or carbon nanotubes cannot be encapsulated, are easily damaged, and have poor stability of pressure sensing signals, and achieve long service life, Controllable process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

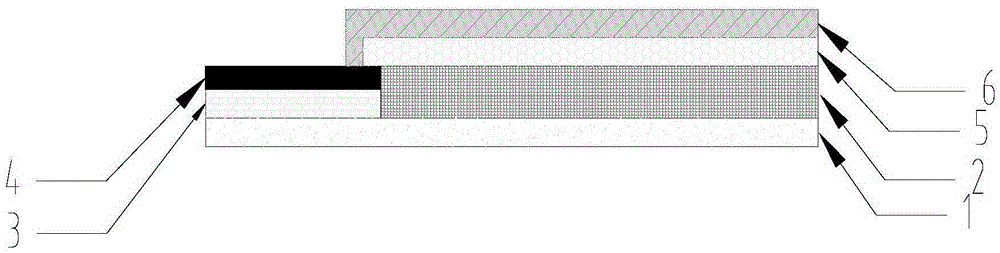

[0067] The back side of the FPC electrode (that is, the side of the PI film) composed of PI film 3 (thickness 125 μm) and copper foil 4 (thickness 30 μm) evaporated gold (thickness 200 nm) is tightly attached to the support layer double-sided adhesive tape and release paper 1 Adhesive: Mix A and B components of silicone E620 evenly at a ratio of 1:1, defoam under vacuum, apply on the double-sided adhesive tape of the support layer and release paper 1, and then heat in an oven at 80°C for 40 minutes Curing, as the induction zone 2.

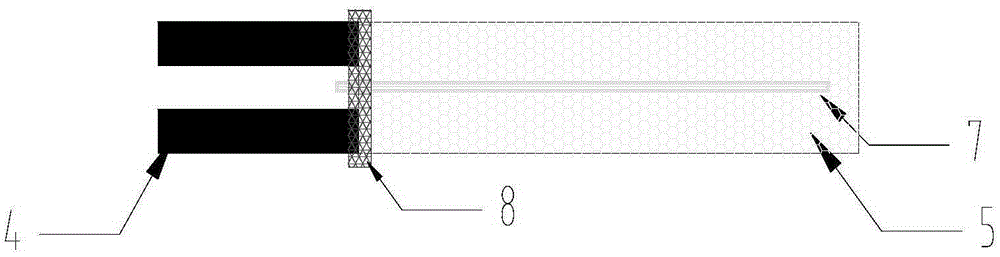

[0068] Graphene is grown by atmospheric pressure CVD, the substrate is 200-mesh copper mesh, the diameter of the copper wire is 45 μm, the mesh is 75×75 μm, the thickness of the prepared graphene is 80-100 nm, and the width of a single graphene mesh is 70 μm, the pore size is 66.5×66.5 μm.

[0069] Lay the graphene-grown copper grid on the FeCl 3 The copper mesh was completely corroded in the solution, and the residual FeCl in the graphene mesh w...

Embodiment 2

[0074] The back of the FPC electrode (that is, the side of the PI film) composed of PI film 3 (thickness 80 μm) and copper foil 4 (thickness 25 μm) evaporated nickel-chromium alloy (thickness 150 nm) is tightly attached to the support layer single-sided PET tape 1 Paste so that there are no gaps and air bubbles between the two layers; mix the main agent and curing agent of PDMS at a ratio of 10:1 to remove air bubbles evenly, then apply it on the support layer single-sided adhesive polyester tape 1, and let it stand for 60 minutes to flow naturally Flatten the surface so that it is on the same plane as the copper foil 4, then evacuate again to remove air bubbles, and then put it in an oven at 60°C for 70 minutes to heat and solidify as the induction zone 2, and finally remove the residual silica gel on the copper foil 4.

[0075] Using the normal pressure CVD method, the graphene growth substrate is a 100-mesh copper mesh, the diameter of the copper wire is 100 μm, and the mesh...

example 3

[0081] The back side of the FPC electrode (that is, the side of the PI film) made of PI film 3 (thickness is 50 μm) and copper foil 4 (thickness is 20 μm) of vapor-deposited nickel (thickness is 250 nm) and OCA glue with a thickness of 175 μm and a thickness of The 125μm PET1 is pasted, the front is covered with a release film, and the three are tightly pasted by roll-to-roll rolling. There are no gaps and air bubbles between the layers, so that the surface of the OCA glue and the copper foil electrode 4 are on the same plane. The OCA glue is used as Sensing zone 2.

[0082] Atmospheric pressure CVD method is used, the graphene growth substrate is 80 mesh copper mesh, the diameter of copper wire is 50 μm, the mesh hole is 200×200 μm, the thickness of the prepared graphene is 55nm, the single width of network graphene is 74 μm, and the aperture is 184×184 μm .

[0083] Place the copper grid on the FeCl after growing graphene 3 The copper wire is completely corroded in the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com