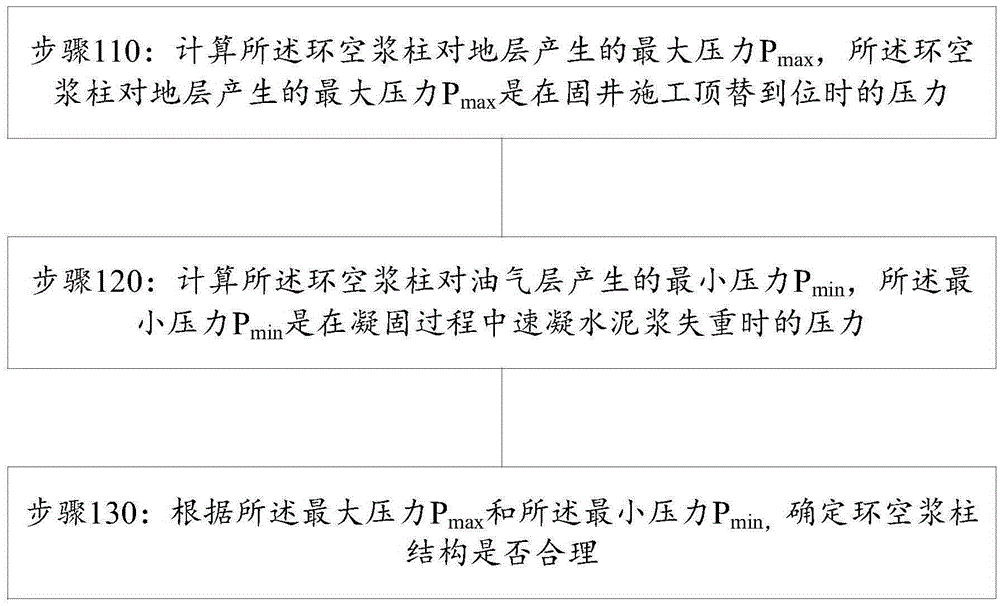

Design method of well cementation annulus slurry column structure

A design method and technology of slurry column structure, which are applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problem of incomplete consideration of factors affecting cementing annular slurry column pressure, and achieve convenient scheme design It can be mastered by on-site construction personnel, the design results are accurate, and the calculation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0080] Example 1: Taking Well XX-1 as an example, the application of the present invention is described in detail.

[0081] Well XX-1 is a vertical well with a drilling depth of 3000m and a drilling fluid density of 1.20g / cm 3 , the fracture (leakage) pressure of the formation is 54.9PMa, the well section of the oil and gas layer is 2700m-3000m, the cement is required to return to a depth of 2000m, and the annular friction when the cementing construction is replaced in place is 1.5MPa, and the design of the cementing annular slurry is reasonable column structure.

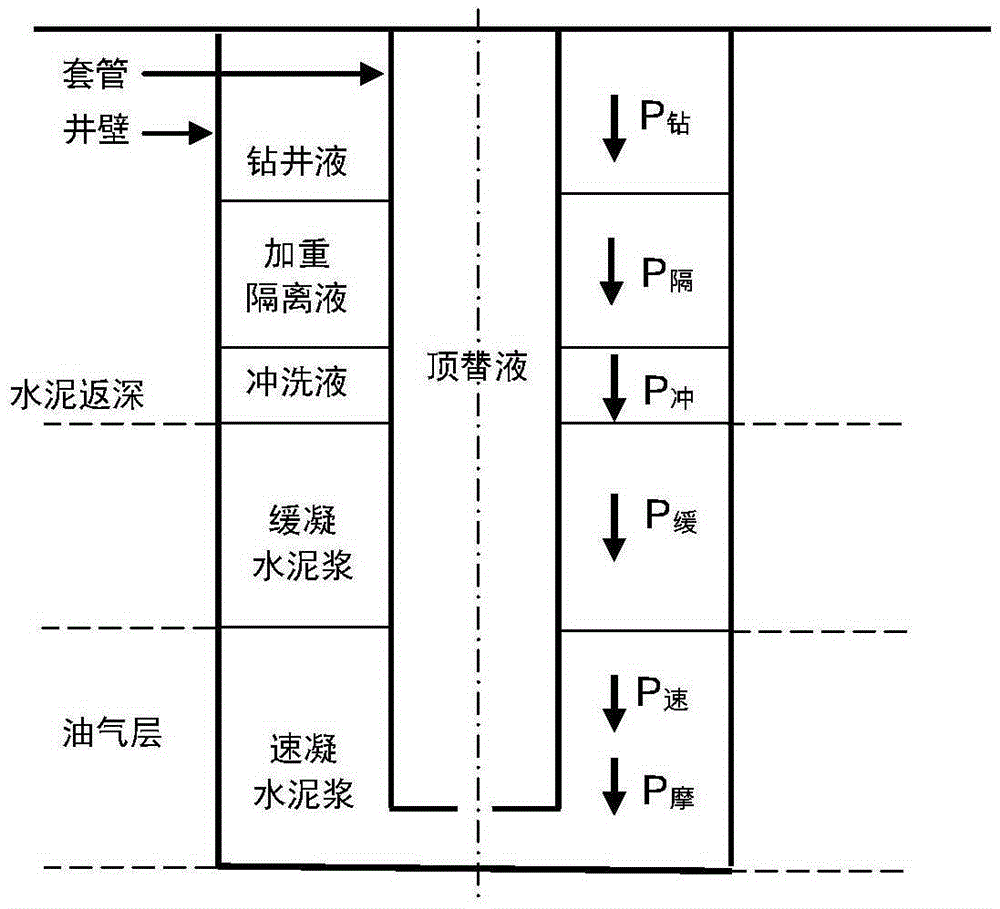

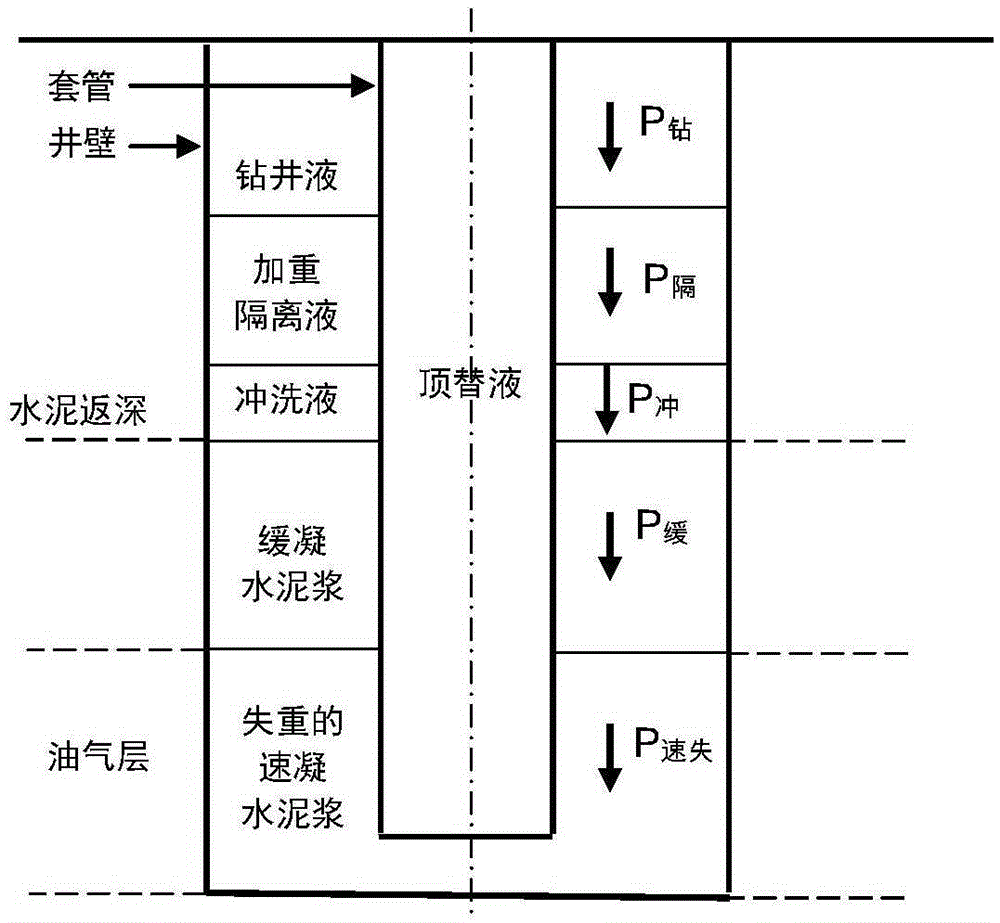

[0082] Step 1: Determine the maximum pressure generated by the slurry column on the formation when the displacement is in place.

[0083] 1. Hydrostatic column pressure of quick-setting cement slurry: 1.90g / cm for quick-setting cement slurry 3 The conventional density, the height is 3000m-2700m=300m.

[0084] P 速 =1.90g / cm 3 ×300m×9.8m / s=5.59MPa

[0085] 2. Hydrostatic column pressure of retarded cement slurry...

example 2

[0106] Example 2: Taking well XX-2 as an example, the application of the present invention is described in detail.

[0107] Well XX-2 is a vertical well with a drilling depth of 3800m and a drilling fluid density of 1.40g / cm 3 , the fracture (leakage) pressure of the formation is 69.5PMa, the well section of the oil and gas layer is 3000m-3800m, the cement is required to return to a depth of 2500m, and the annular friction resistance when the cementing construction is replaced in place is 2.0MPa, and the design of the cementing annular slurry is reasonable column structure.

[0108] Step 1: Determine the maximum pressure generated by the slurry column on the formation when the displacement is in place

[0109] 1. Hydrostatic column pressure of quick-setting cement slurry: 1.90g / cm for quick-setting cement slurry 3 The conventional density, the height is 3800m-3000m=800m.

[0110] P 速 =1.90g / cm 3 ×800m×9.8m / s=14.90MPa

[0111] 2. Hydrostatic column pressure of retarded ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com