Carbon fiber oiling agent with non-silicon oiling agent and silicon-containing oiling agent compounded for use and preparation method of carbon fiber oiling agent

A technology of carbon fiber and silicone oil, applied in the direction of carbon fiber, fiber treatment, carboxylic acid halide preparation, etc., can solve the problem of insufficient heat resistance, and achieve improved heat resistance, good heat resistance and lubricity, good protection and The effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0055] A non-silicon oil agent / silicon-containing oil compound compounded carbon fiber oil, which is obtained by compounding a non-silicon oil agent and a silicon-containing oil agent;

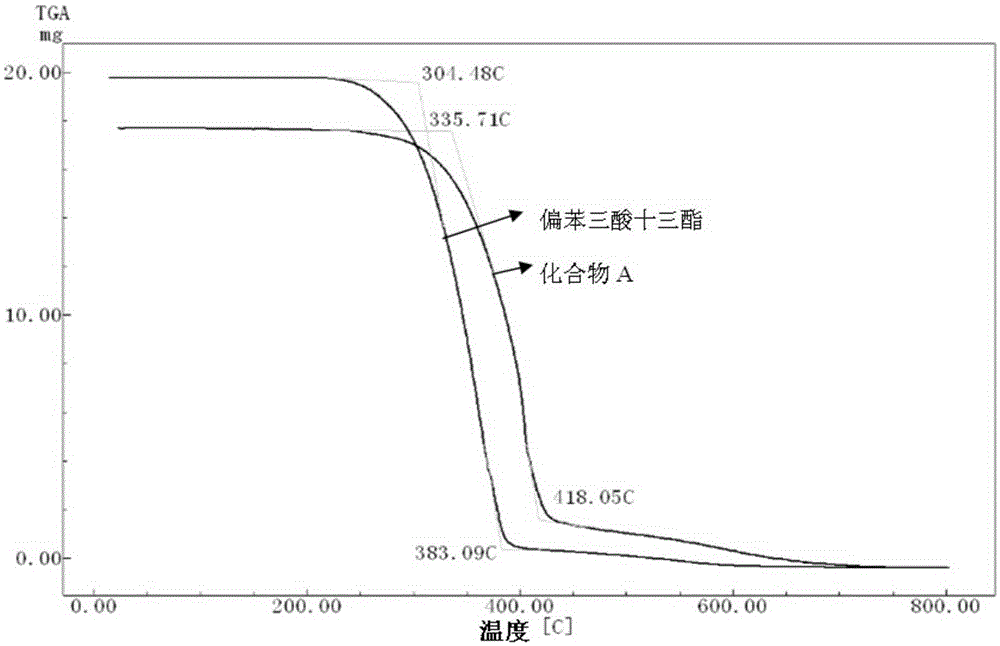

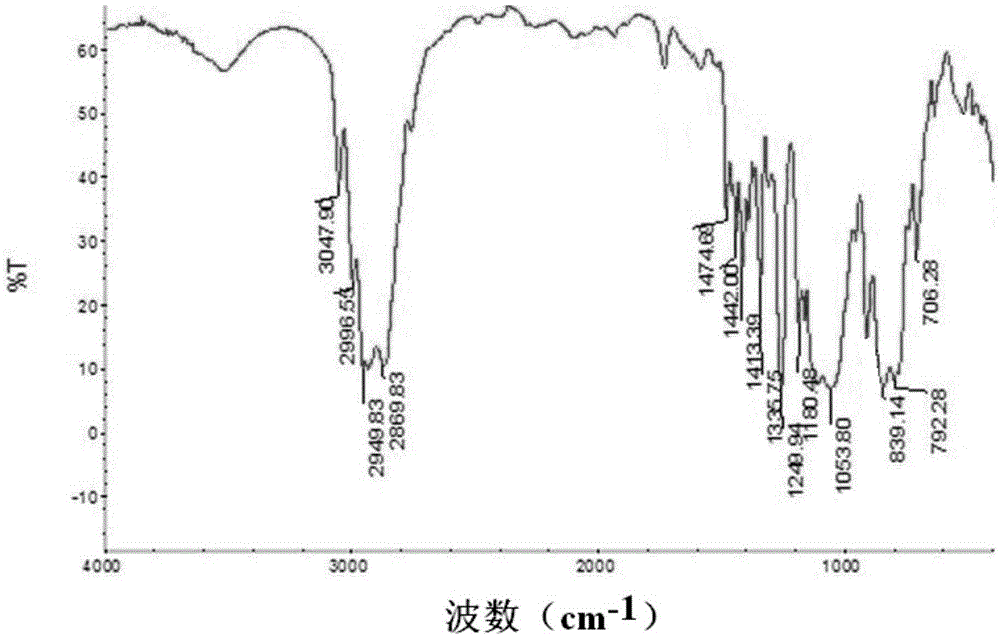

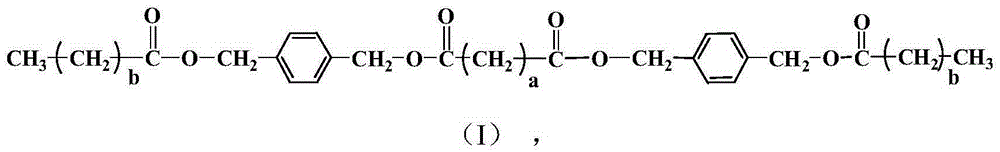

[0056] The non-silicone oil agent comprises 100 parts by mass of compound A, 1-5 parts by mass of antioxidant and 20-30 parts by mass of surfactant; said compound A has a structure shown in formula (I):

[0057]

[0058] In formula (I), a=0~3, b=6~10;

[0059] The silicone-containing oil agent includes 100 parts by mass of side chain aminopropyl modified silicone oil, 3-10 parts by mass of substance B and 20-30 parts by mass of surfactant; the substance B has the structure shown in formula (II) :

[0060]

[0061] In formula (II), z=2-5.

[0062] The preparation method of compound A:

[0063] (1) Add 103.5g of terephthalamide and 300mL of xylene into a 1000mL four-necked flask, stir and raise the temperature to 90°C, add 163.5g of lauroyl chloride dropwise, and pass in N 2 , take awa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Ammonia value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com