Preparation method of microencapsulated gardenia yellow pigment

A technology of gardenia yellow pigment and microencapsulation, applied in the direction of organic dyes, etc., can solve the problem of not being able to color stably for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

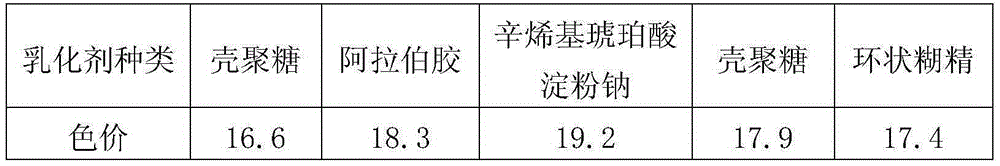

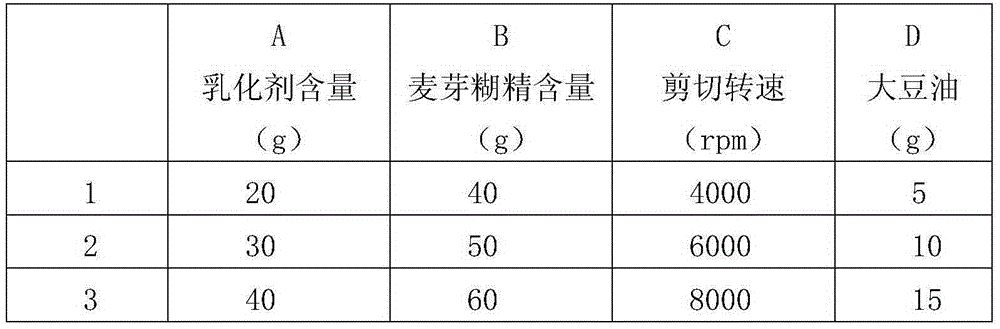

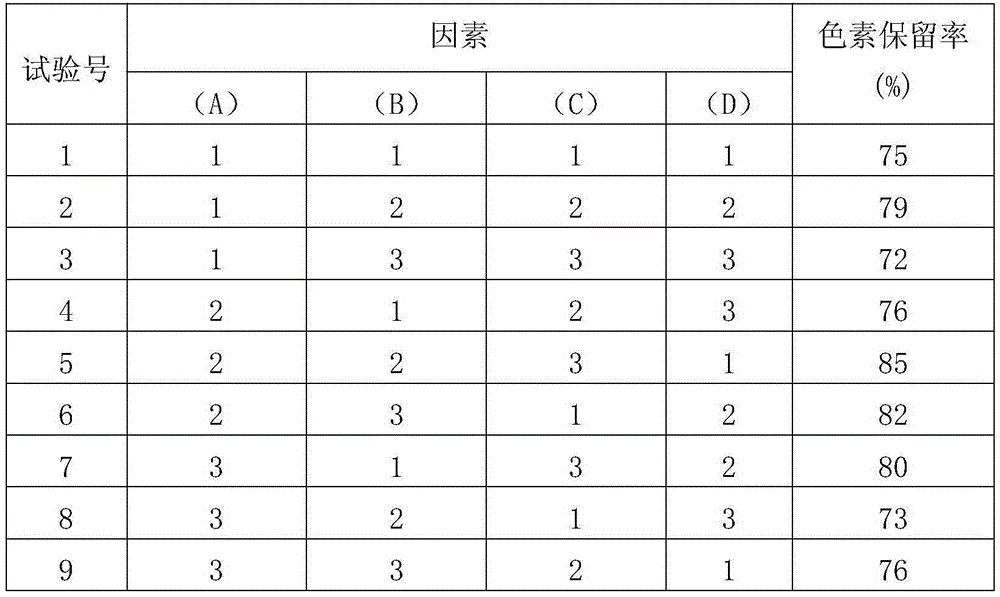

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of microencapsulated gardenia yellow pigment, comprising the steps of:

[0048] (1) Water phase preparation: get 30 parts by weight of sodium starch octenyl succinate, 50 parts of maltodextrin, and 10 parts of gardenia yellow pigment with a color value of 200 and mix them with water of the same weight as the above-mentioned mixture. The mixture, which is completely dissolved at 50°C as the water phase;

[0049] (2) Oil phase preparation: take 10 parts by weight of soybean oil and stir evenly at 50°C, and use it as the oil phase after completely dissolving;

[0050] (3) Emulsification: Cut the aqueous phase solution for 15 minutes at a shear speed of 8000rpm in a high-speed shearing machine, add the oil phase to the water phase, and slowly add while shearing, so that the emulsifier embeds the oil phase and pigment Molecules and oil phases are completely added and continue to shear for 10 minutes, so that no oil layer floats on the surface of the mat...

Embodiment 2

[0054] A preparation method of microencapsulated gardenia yellow pigment, comprising the steps of:

[0055] (1) Water phase preparation: get the gum arabic of 35 parts by weight, the maltodextrin of 45 parts, the gardenia yellow pigment that the color value of 10 parts is 200 is mixed, dissolve the mixture with the water equal weight of above-mentioned mixture, make it in Completely dissolved at 60°C as the water phase;

[0056] (2) Oil phase preparation: take 10 parts by weight of soybean oil and stir evenly at 60°C, and use it as the oil phase after completely dissolving;

[0057] (3) Emulsification: Cut the aqueous phase solution for 15 minutes at a shear speed of 8500rpm in a high-speed shearing machine, add the oil phase to the water phase, and slowly add while shearing, so that the emulsifier embeds the oil phase and pigment Molecules and oil phases are completely added and continue to cut for 10 minutes, so that no oil layer floats on the surface of the material, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com