Method and equipment thereof for producing caramel pigment

A technology of caramel pigment and equipment, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve uneconomical problems and achieve the effect of reducing heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

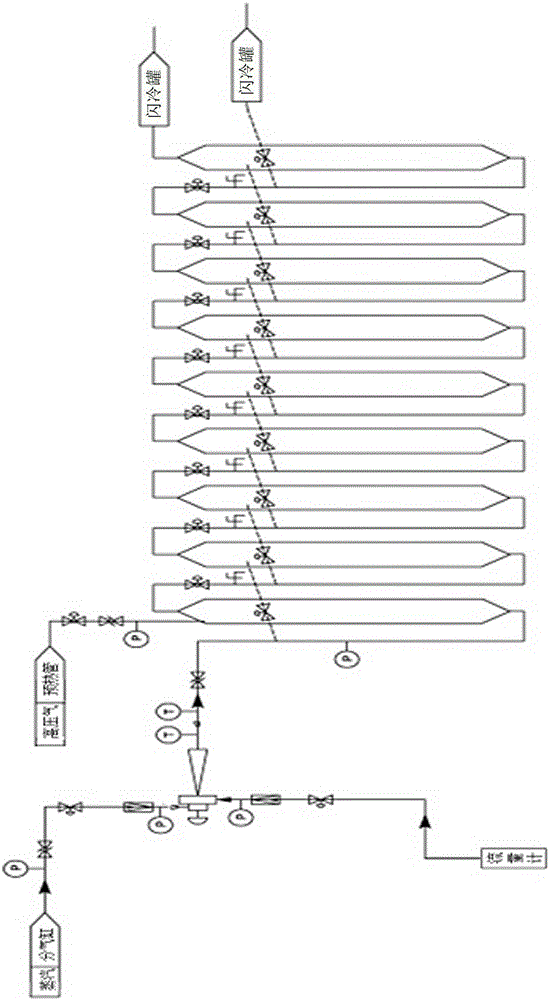

[0030] The laminar flow reaction kettle is heated by a coil, and the material is heated by heat exchange through the contact between the material and the coil through which steam is passed inside, and then the heated material is stirred evenly.

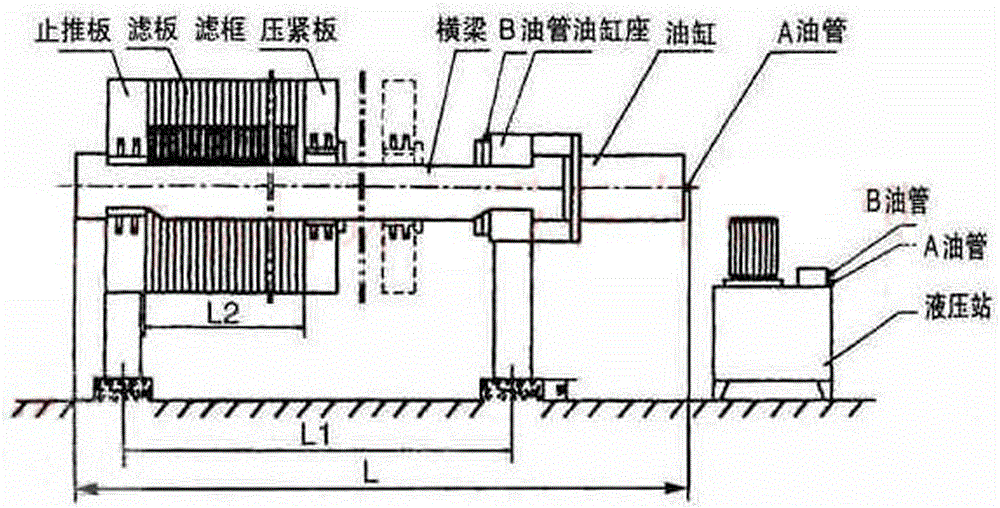

[0031] The plate and frame filter press includes a filter chamber, the filter chamber is composed of alternately arranged filter plates and filter frames; the surface of the filter plate has grooves, and its protruding parts are used to support the filter cloth; the edges of the filter frame and the filter plate There are through holes in the corners, which form a complete channel after assembly, and can pass into the suspension, washing liquid and lead out the filtrate.

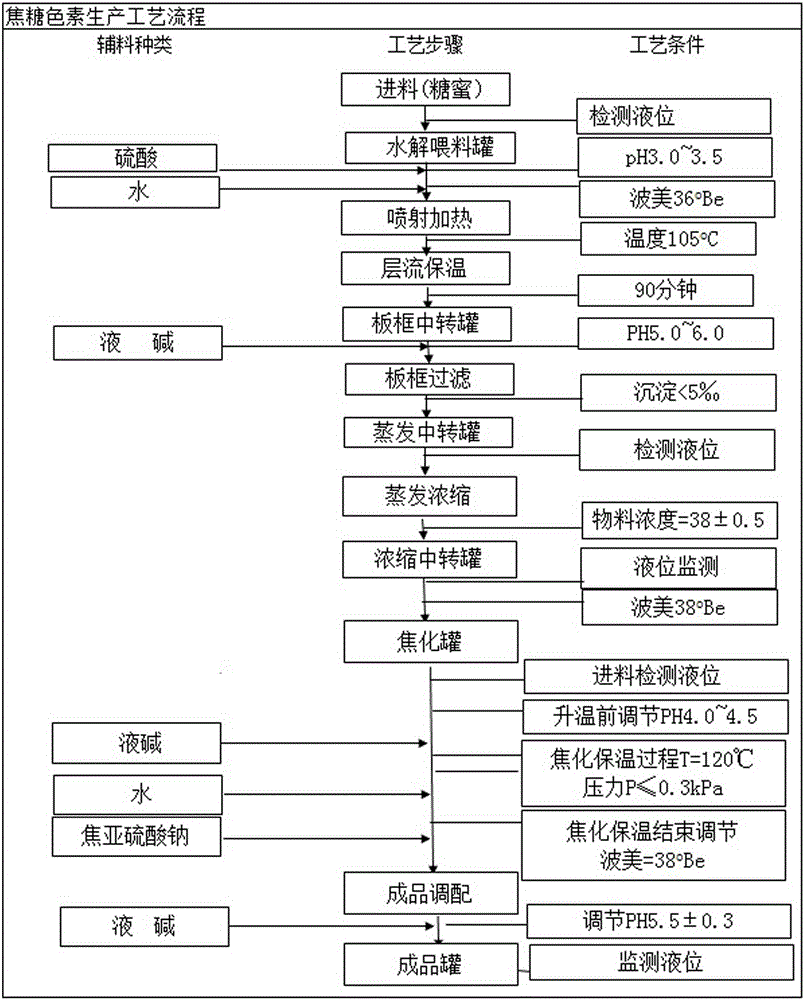

[0032] The process method adopted by the above-mentioned equipment for producing caramel pigment comprises the following steps:

[0033] (1) Put the waste molasses from the raw material tank into the material pre-melting tank in advance, add sulfuric acid and water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com