Polymer flocculant, its preparation method and application

A polymer flocculant and initiator technology, applied in the field of its preparation, sewage purifier, polymer flocculant, can solve the problems of limited use, weak treatment effect of heavy metal ions, etc., to achieve easy operation control, excellent removal effect, process simple mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

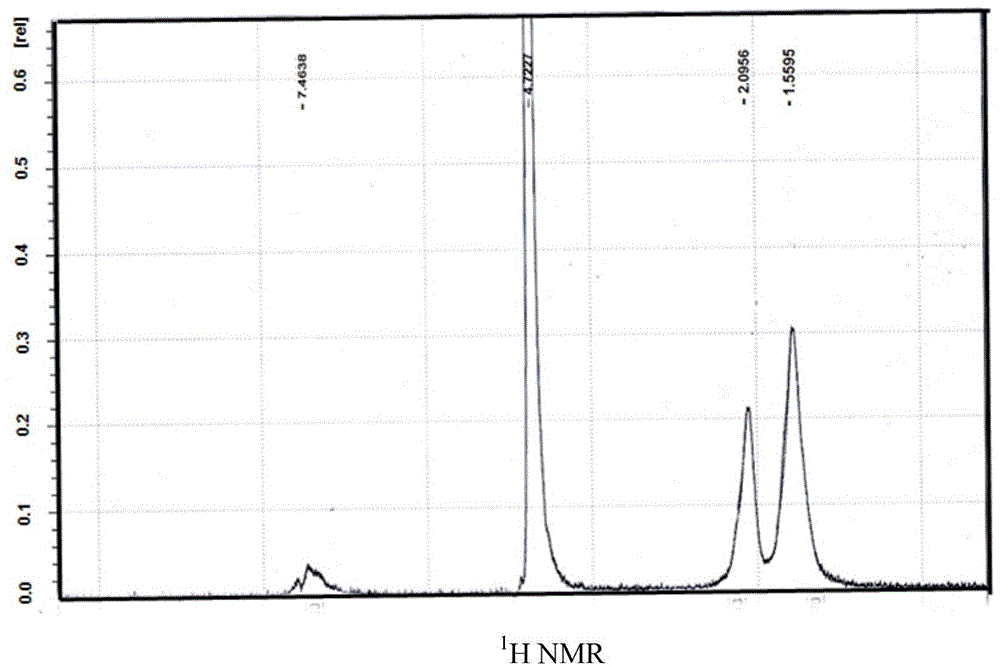

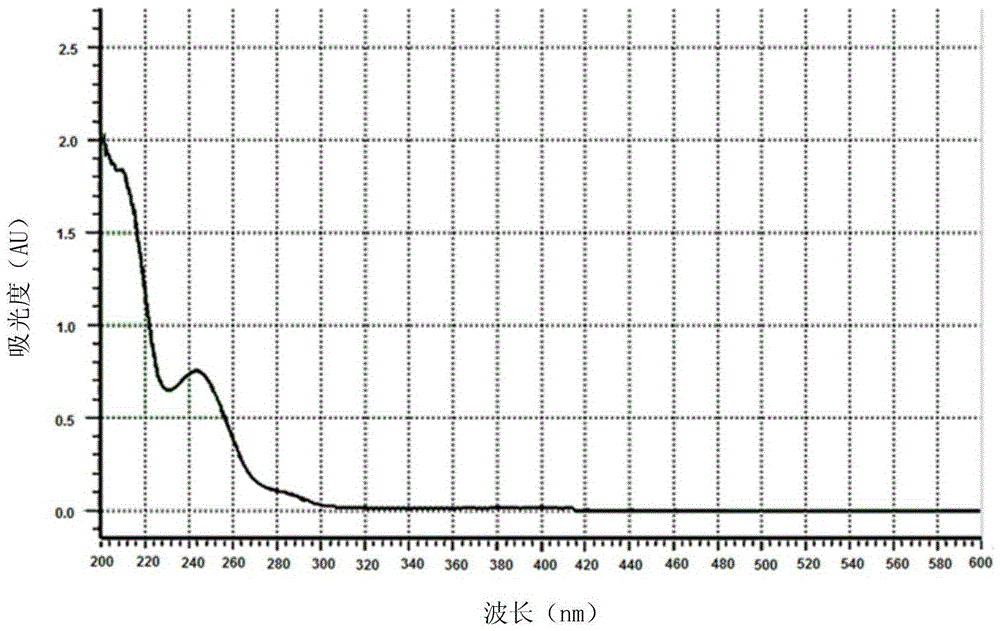

[0034] Under the condition of nitrogen protection, the blend of 1.812 grams of 3-acrylamidophenylboronic acid and 2.955 grams of acrylamide was mixed with 550 grams of 10w% aqueous methanol solution and stirred at a constant speed to fully dissolve it; then the solution Heat to 50° C. and slowly add 6 mg of azobisisobutylamidine hydrochloride dropwise at a stirring speed of 100-400 rpm. After the dropwise addition of azobisisobutylamidine hydrochloride was completed, the polymerization reaction was carried out for another 10 h. After the reaction, the reaction residue was lowered to room temperature and collected into a dialysis bag with a molecular weight cut-off of 12,000-14,000 for separation. The separation time was 1 day, and then the resulting product was freeze-dried to obtain the final product, namely polymer flocculation agent ( 1 For H NMR and UV spectra see Figure 1-Figure 2 ), and its number average molecular weight is 1.5 million to 4 million. In a dry environ...

Embodiment 2

[0036] Under the condition of nitrogen protection, 1.242 grams of 3-acrylamidophenylboronic acid and 4.231 grams of acrylamide blend were mixed with 400 grams of 15w% isopropanol aqueous solution and stirred at a constant speed to make it fully dissolved; then the The solution was heated to 55° C. and 7 mg of tert-butyl peroxide was slowly added dropwise at a stirring speed of 100-400 rpm. After the dropwise addition of tert-butyl peroxide was completed, the polymerization reaction was carried out for another 6 h. After the reaction, the reaction residue was lowered to room temperature and collected into a dialysis bag with a molecular weight cut-off of 12,000-14,000 for separation. The separation time was 2 days, and then the resultant was freeze-dried to obtain the final product, namely polymer flocculation agent, its number average molecular weight is 1.5 million to 4 million. In a dry environment, the polymer flocculant can be stored stably for more than 2 years.

Embodiment 3

[0038] Under the condition of nitrogen protection, mix 1.223 grams of 3-acrylamidophenylboronic acid and 5.832 grams of acrylamide blend with 1000 grams of 20w% ethanol aqueous solution and stir at a constant speed to fully dissolve it; then the solution Heat to 65° C. and slowly add 8 mg of 2,2′-azobis(2-methylpropionamide) dihydrochloride dropwise at a stirring speed of 100-400 rpm. After the dropwise addition of 2,2'-azobis(2-methylpropionamide) dihydrochloride was completed, the polymerization reaction was carried out for another 14 hours. After the reaction, the reaction residue was lowered to room temperature and collected into a dialysis bag with a molecular weight cut-off of 12,000-14,000 for separation. The separation time was 3 days, and then the resultant was freeze-dried to obtain the final product, namely polymer flocculation agent, its number average molecular weight is 1.5 million to 4 million. In a dry environment, the polymer flocculant can be stored stably f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com