Efficient helium gas recovery apparatus

A high-efficiency technology for helium recovery, applied in the fields of inert gas compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems affecting the economic benefits of the purification process, the recovery efficiency and low purity, etc., to improve recovery economic benefits and simple structure. , the effect of reducing the amount of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

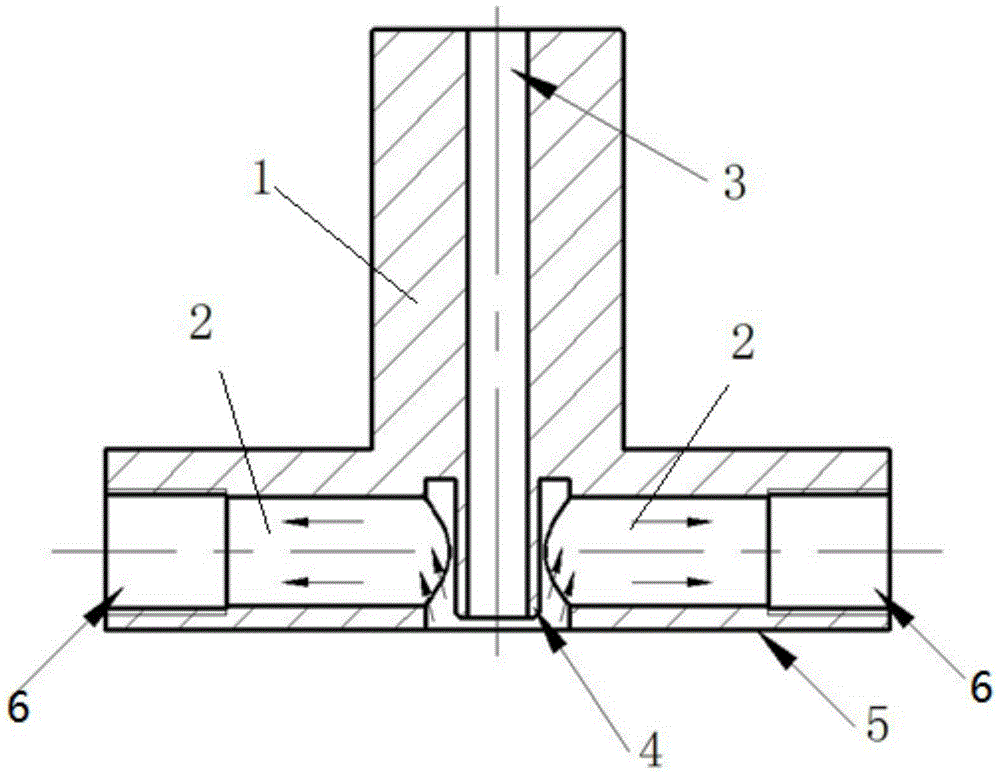

[0010] Such as figure 1 As shown, the high-efficiency helium recovery device includes a convex-shaped device body 1, the bottom of the device body 1 is a joint surface 5 connected to the cavity to be recovered helium, and a helium gas is vertically penetrated in the middle of the device body 1. Channel 3, the lower part of the device body 1 is located on both sides of the helium channel 3, and recovery channels 2 are respectively provided. A spoiler 4 is respectively provided in the two recovery channels 2, and a suction pump is respectively provided at the outer end of the two recovery channels 2. Air port 6.

[0011] The detailed description of the present invention is as follows in conjunction with accompanying drawing:

[0012] The device of the present invention is connected to the cavity for recovering helium through the joint surface 5, and the helium channel 3 is aligned with the helium cavity. The helium in the cavity is recovered from the helium recovery channel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com