A device for adjusting the magnetic force of a printing magnetic table by adjusting the screw and the cylinder element

A technology for adjusting screw and magnetic table, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of limited fabric types and width, unsuitable for heavy and wide fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

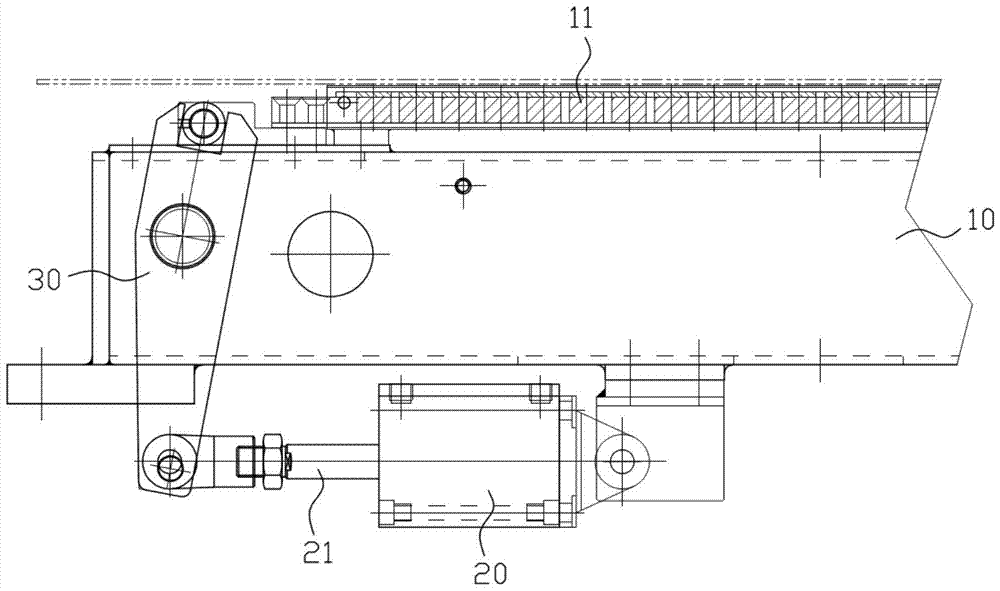

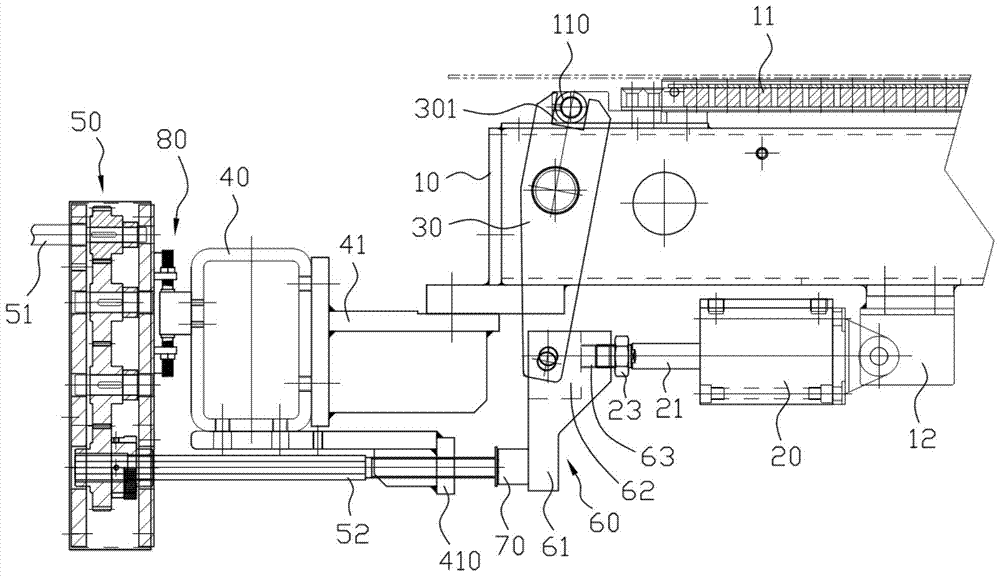

[0049] Such as figure 2 , a device for adjusting the magnetic force of a printing magnetic table in cooperation with an adjusting screw and a cylinder element, including a cylinder element 20 installed at the bottom of the magnetic table support body 10, a central shaft 21 connected to the piston of the cylinder element, and the middle part pivotally connected to the magnetic table support body The rocker arm 30; the bottom end of the rocker arm is connected with the central shaft, and the top end of the rocker arm is connected with the printing magnetic table 11 on the magnetic table support body.

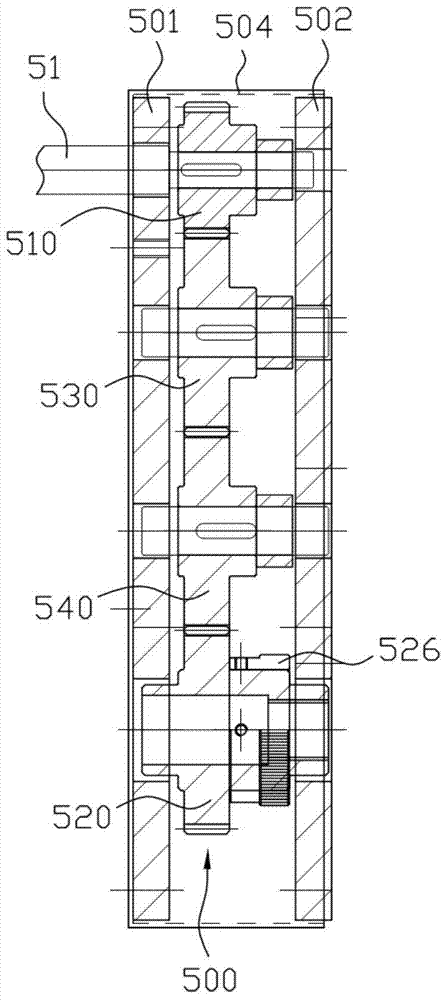

[0050] Such as figure 2 The device for adjusting the magnetic force of the printing magnetic table with the screw and the cylinder element of the present invention also includes a gear box 50 installed on the outer wall of the side beam 40, a gear set 500 installed in the gear box, and connected with the driving gear 510 in the gear set. The transmission rod 51 and the adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com