Plastic hot riveting device for automobile lamp

A plastic and hot riveting technology, which is applied in the field of plastic hot riveting devices for car lights, can solve the problems of prolonging the riveting time of lamps, failing to achieve rapid heating, and long heating time of the riveting head, so as not to affect the production cycle, simplify the riveting process, The effect of improving riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

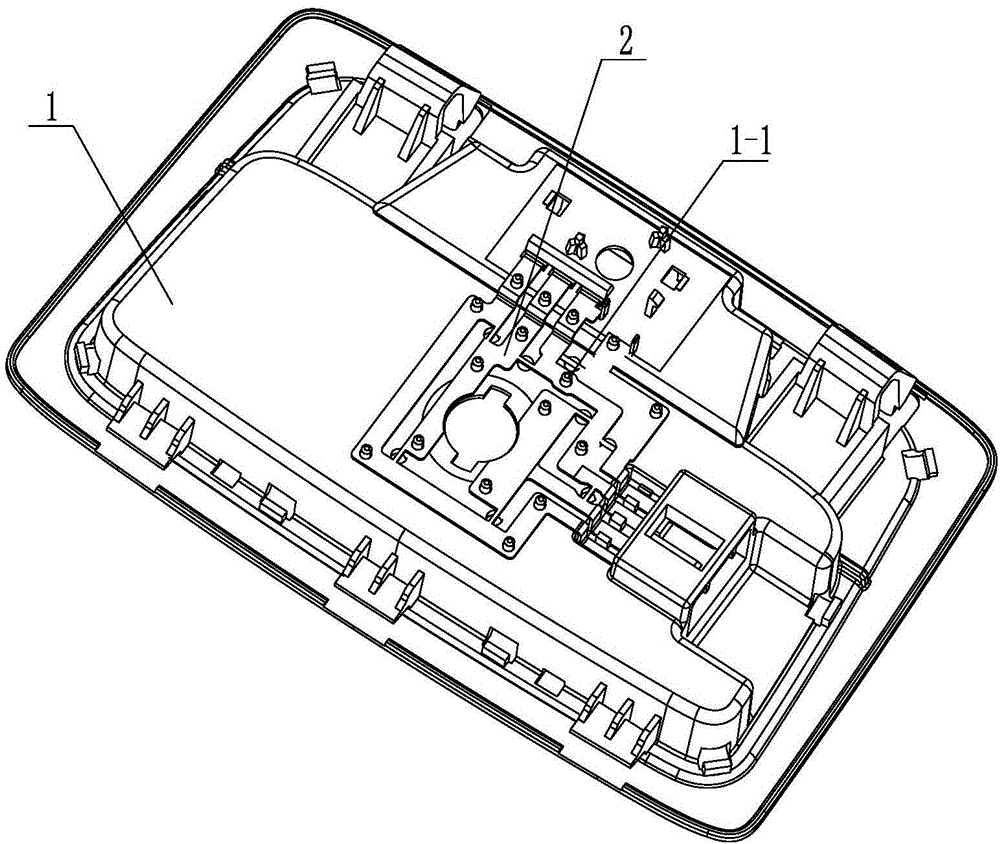

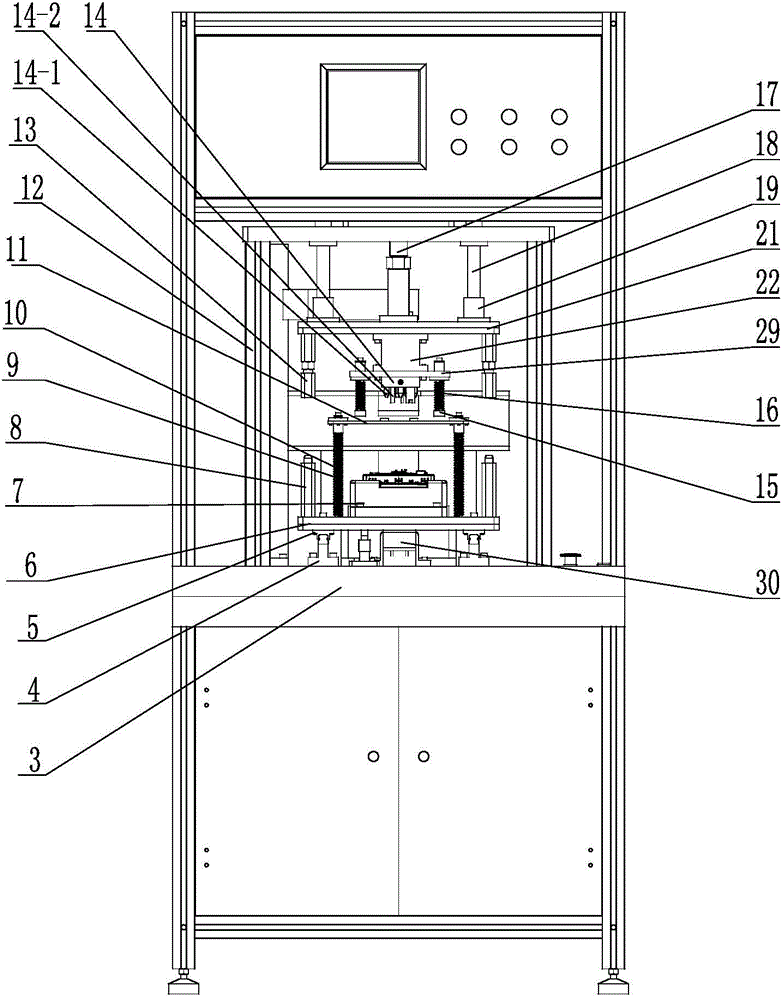

[0020] See Figure 2-7 As shown, the plastic hot riveting device for vehicle lights of the present invention includes a lamp body positioning mechanism, a riveting mechanism, a riveting head grabbing mechanism and a heating mechanism installed on the workbench 3,

[0021] See Figure 2-5 As shown, the lamp body positioning mechanism of the present invention includes a push cylinder 30, a lamp body positioning seat 7 and a floating positioning seat. The push cylinder 30 installed on the workbench 3 is connected with the lamp body positioning seat 7, and the lamp body positioning seat 7 is arranged on the working table. The guide rail 4 on the table 3 can be moved, and the lamp body positioning seat 7 is pushed to move along the guide rail 4 on the worktable 3 by the push cylinder 30, so as to realize the placement and removal of the lamp body 1 and the circuit board, and the placement and removal of the riveting head 32. Take and riveting. See Figure 2-5 As shown, the lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com