An automatic speed regulating device for extrusion and winding

A technology of automatic speed regulation and speed regulation mechanism, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems that the winding tension cannot be accurately realized, so as to reduce the frequency of manual operations and save land. cost, effect of making up for limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe in detail the technical content, structural features, goals and effects achieved of an automatic speed regulating device for extrusion and winding of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

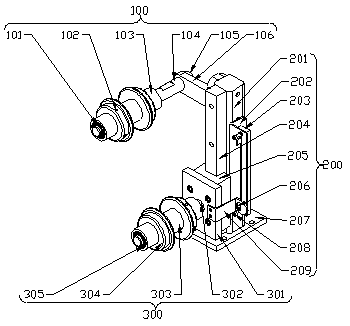

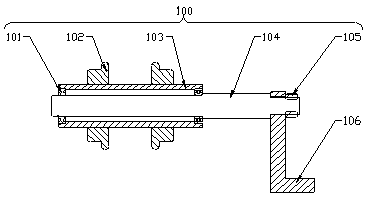

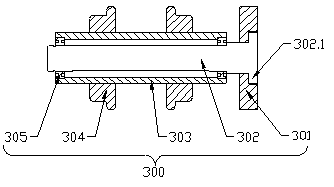

[0030] Such as Figure 1 to Figure 3 As shown, an embodiment of an automatic speed regulating device for extrusion and winding of the present invention is disclosed, including a stationary guide wheel assembly 100, a speed regulating mechanism 200, a floating guide wheel assembly 300, and a cantilever 106 welded and fixed on the pillar of the speed regulating mechanism 201, one end of the toggle piece 209 is fixed on the support plate 301 and the buttonhole at the other end is set on the potential slide 206, the output signal line of the straight slide potentiometer 203 is connected to the frequency converter (not shown in the figure), and the floating shaft 302 adopts annular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| secant modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com