Polishing machine

A polishing machine and polishing belt technology, applied in the field of polishing machines, can solve the problems of poor polishing effect and affecting the work of polishing machines, and achieve the effects of improving polishing effect, uniform polishing effect and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

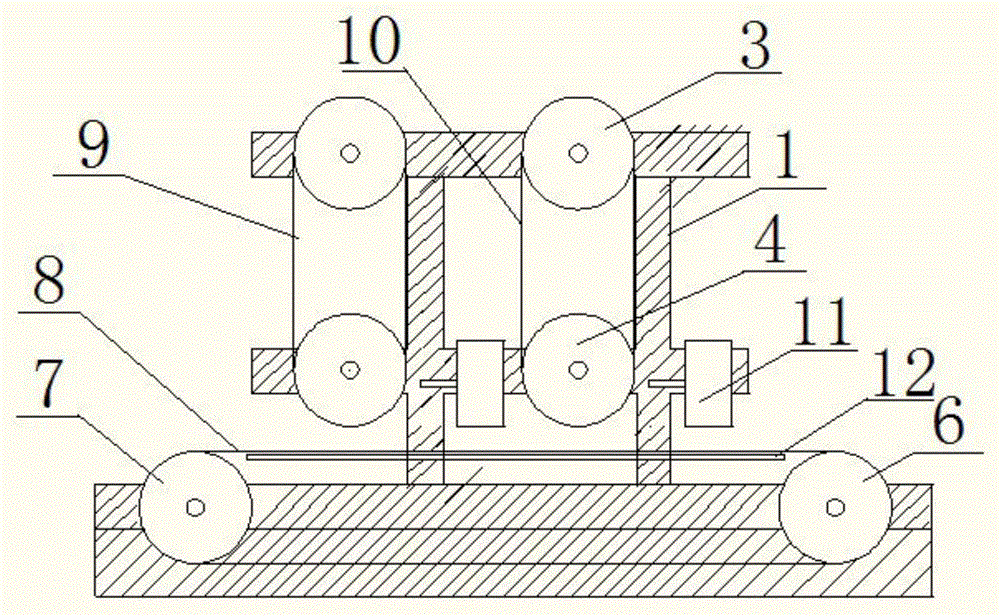

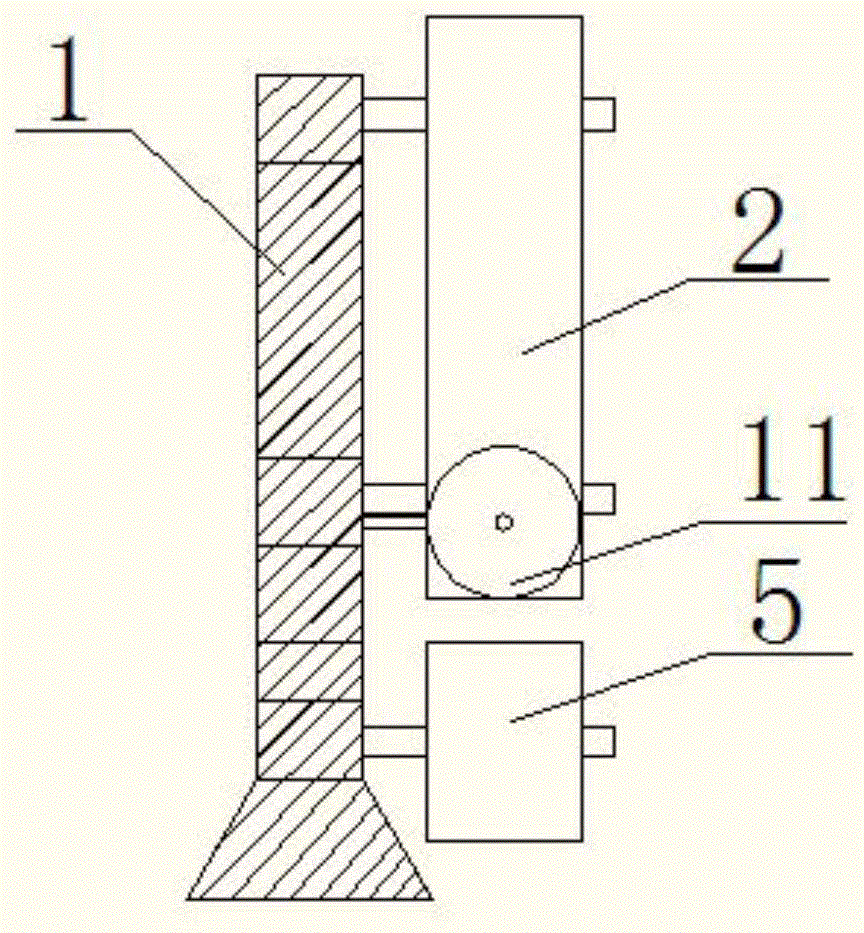

[0015] Such as Figure 1-2 As shown, a polishing machine includes a fixed support 1, a delivery system 5, a polishing system 2 and a cleaning system 11, and is characterized in that the delivery system 5, the polishing system 2 and the cleaning system 11 are connected to the fixed support, and the The cleaning system 11 is immediately behind the polishing system 2, and the conveying system 5 is located below the cleaning system 11 and the polishing system 2. The conveying system 5 includes a conveying belt 8 and a conveying drive assembly, and the conveying belt 8 makes steps Progressive circular movement, the polishing system 2 includes a polishing drive assembly, a driving wheel 3, a driven wheel 4 and a polishing abrasive belt, and the polishing abrasive belt is tensioned on the driving wheel 3 and the driven wheel 4, and the cleaning system 11 It includes an annular brush and a cleaning drive assembly, the distance between the polishing system 2 and the cleaning system 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com