Large-aperture ultra-precise grinding machine integrated system

An integrated system, ultra-precision technology, applied in the field of three-axis grinder, large-caliber ultra-precision grinder integrated system, can solve the problems of low detection efficiency, insufficient precision, high price, etc., to achieve error-free, high machining accuracy and efficiency, good The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

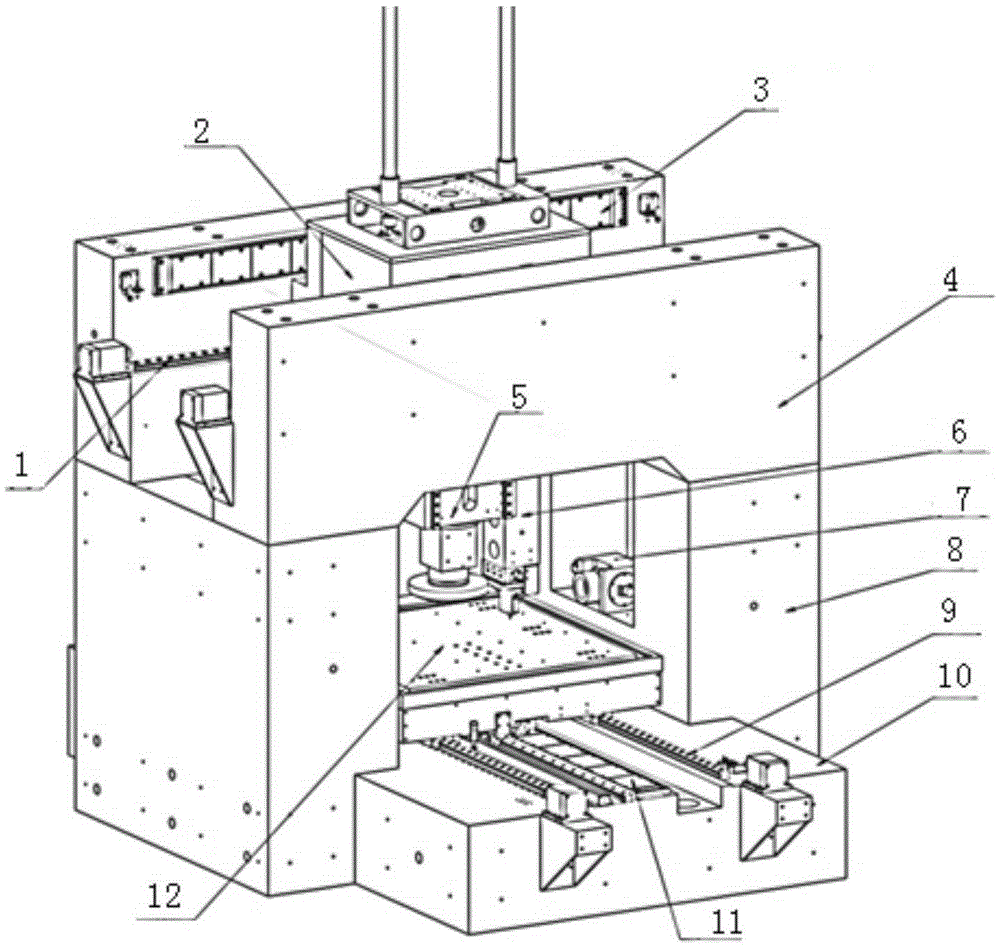

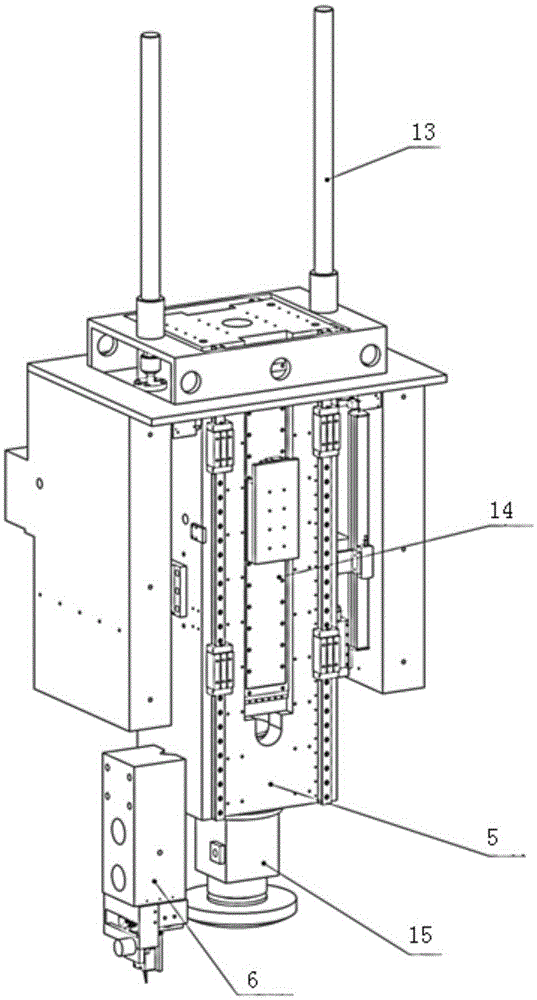

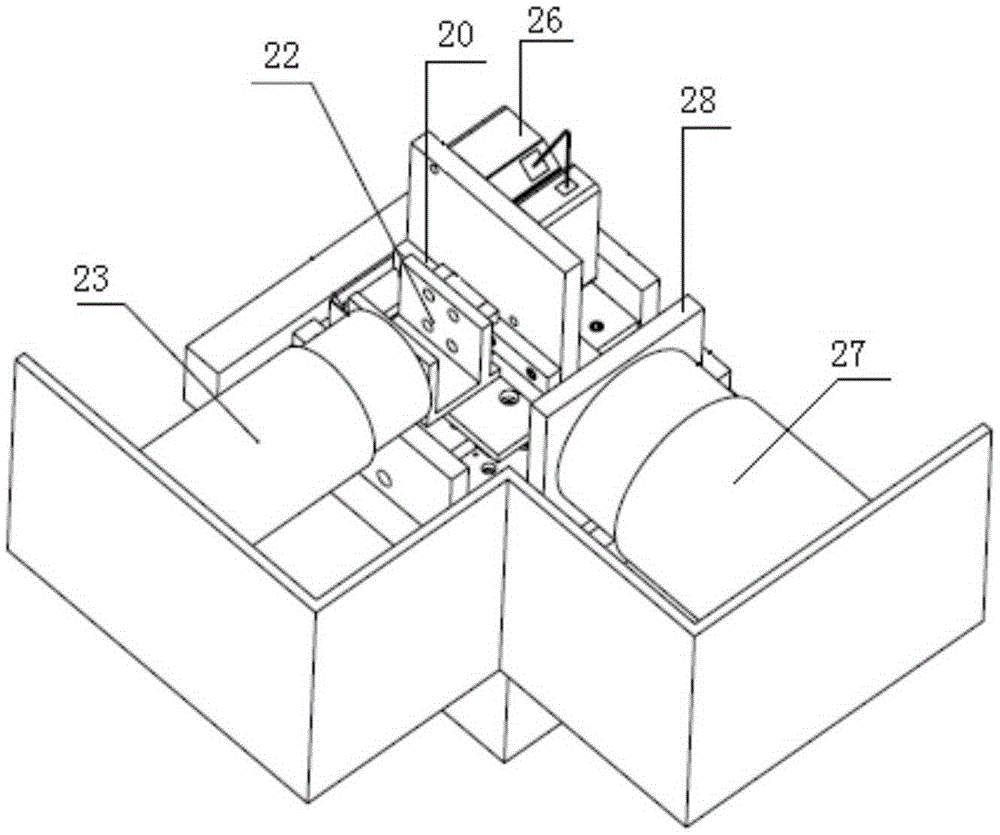

[0026] The detection object of the present invention may be a large space mirror. Such as figure 1 with 2 As shown, the large-diameter ultra-precision grinding machine integrated system of the present invention is a double-beam structure granite machine tool structure, including a machine base 10, a column 8, a beam 4, a machine tool Y-axis guide rail 1, a Y-axis slide box 2, and a Y-axis linear motor 3 , Z-axis spindle box 5, two-dimensional vibration-assisted laser scanning in-position detection system 6, X-axis workbench 12, machine tool X-axis guide rail 9, X-axis linear motor 11, in-position grinding wheel dressing device 7, balance hydraulic cylinder 13, Z Shaft linear motor 14 and hydrostatic spindle 15.

[0027] The connection relationship is: the column 8 connects the machine base 10 and the beam 4 together; the Y-axis guide rail 1 of the machine tool and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com