Device with air cylinder driving magnet to take and place steel ring

A technology of cylinder and magnet, which is applied in the field of the device where the cylinder drives the magnet to pick and place the steel ring, which can solve the problems of inconvenient installation, high cost, deformation of the steel ring, etc., and achieve the effect of avoiding quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention discloses a steel ring pick-and-place device with a new structure. The device uses a cylinder to drive a magnet to pick and place a steel ring. quality risk.

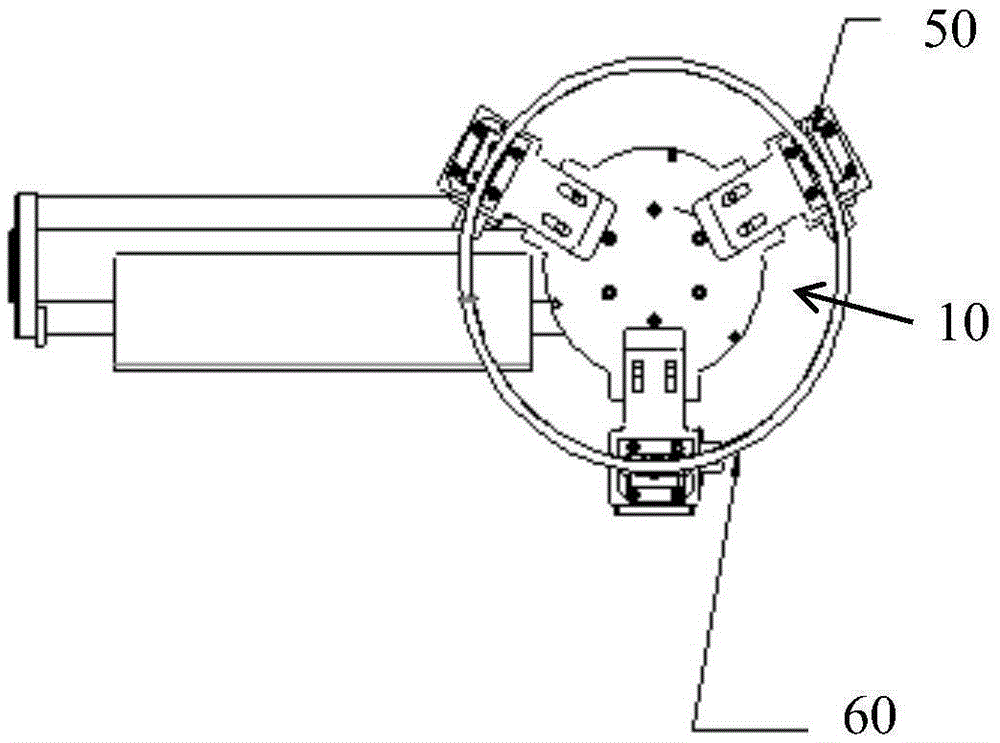

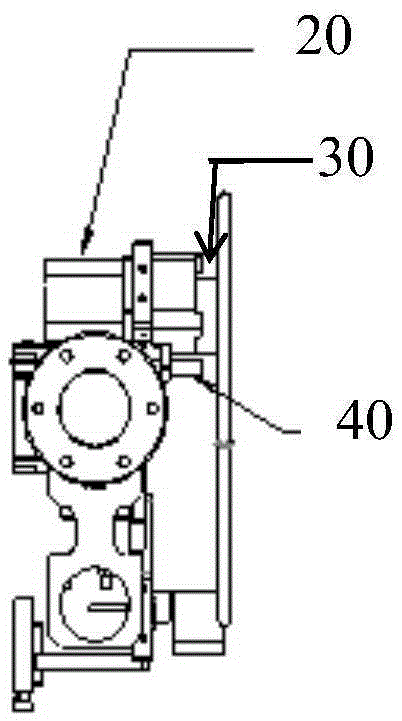

[0012] Such as figure 1 and figure 2 As shown, a cylinder drives a magnet to pick and place a steel ring device, which includes a control power supply, a support base 10 and a cylinder 20 located on the support base 10 . The device that the cylinder drives the magnet to pick and place the steel ring also includes a solenoid valve connected to the cylinder 20 and used to control the cylinder 20, a control circuit, a block 30 connected to the cylinder 20, a sensor 40 located on the block 30 and a device The magnet 50 on the sensor 40 side.

[0013] The magnet 50 is disposed inside the blocking block 30 . Cylinder 20 is a push-pull cylinder. The sensor 40 is installed on the outer wall of the block 30 . The device integrates the cylinder 20 and its electromagnetic valve, control circuit, support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com