A combined positioning method for a general-purpose single-crystal turbine working blade module

A combined positioning and blade technology, applied in the direction of manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problem of blade wax parts inclination and other problems, achieve good crystal orientation, improve work efficiency, and improve the effect of preparation quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present application will be further described below in combination with specific embodiments and accompanying drawings.

[0020] The combined positioning method of the universal single crystal turbine working blade module in this embodiment is carried out according to the following steps:

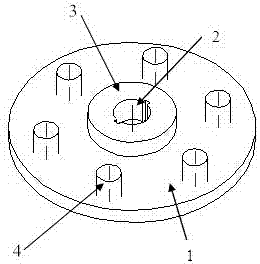

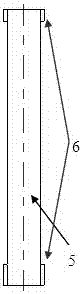

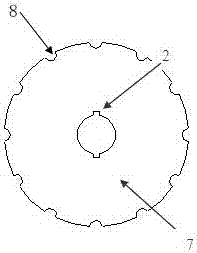

[0021] (1) Set up a central column tube positioning groove 2 on the central column tube insertion port 3 in the center of the chassis 1 in the blade pouring device, such as figure 1 As shown, the same middle column tube positioning groove 2 is opened on the middle column tube insertion port at the center of the upper disc 7, as image 3 Shown, all be provided with positioning pin 6 on the head and the afterbody of column tube 5, as figure 2 As shown, the size of the center column tube positioning groove 2 matches the positioning pin 6, and the chassis 1, the center column tube 5 and the upper disc 7 are assembled into one body through the positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com