Measuring pipe dredge device

A technology for measuring pipelines and tubular shapes, which is applied in the field of measuring pipeline dredging devices, which can solve problems such as leakage of toxic media, blockage of pressure measurement, and endangering the safety of maintenance personnel, etc., and achieve the effects of thorough pipeline dredging, simple and labor-saving operation, and prevention of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

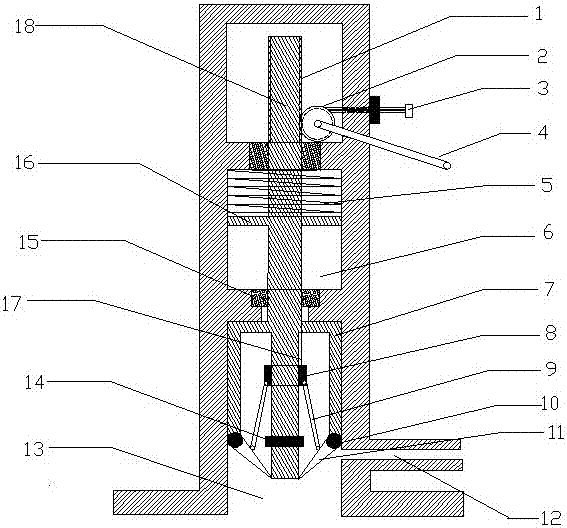

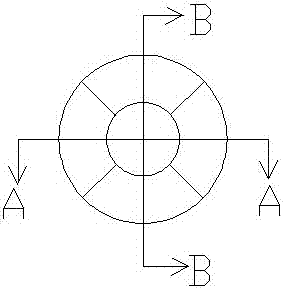

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

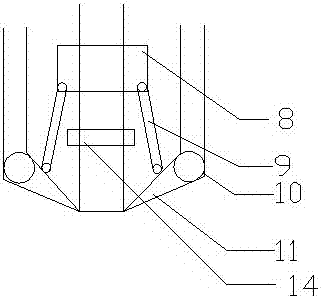

[0027] Such as Figure 1-4 As shown, the measurement pipeline dredging device of the present embodiment comprises a tubular shell with one end closed and one end open, a shovel bracket 7 is installed inside the tubular housing, and an umbrella-shaped shovel 11 is installed on the described shovel bracket. The blade bracket is connected to the pulling drive device, and the umbrella-shaped blade is also connected to the shrinking device.

[0028] In the device for dredging the measuring pipeline, the pulling drive device includes a displacement chamber 6 arranged inside the tubular housing, a blade connecting rod 18 connected to the blade bracket, and the blade rod 18 connected to the blade bracket. The middle part of the knife connecting rod is provided with a fixed block 16, and the fixed block is located in the displacement chamber, and the upper part of the fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com