Automatic spraying device for tubular metal heat exchanger outer walls

An automatic spraying and heat exchanger technology, applied in the direction of the spraying device, can solve the problems of uneven spraying speed, time-consuming and laborious, easy to settle, etc., and achieve the effect of reducing labor intensity, improving spraying quality, and increasing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but it does not constitute a limitation of the present invention, and is only used as an example. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

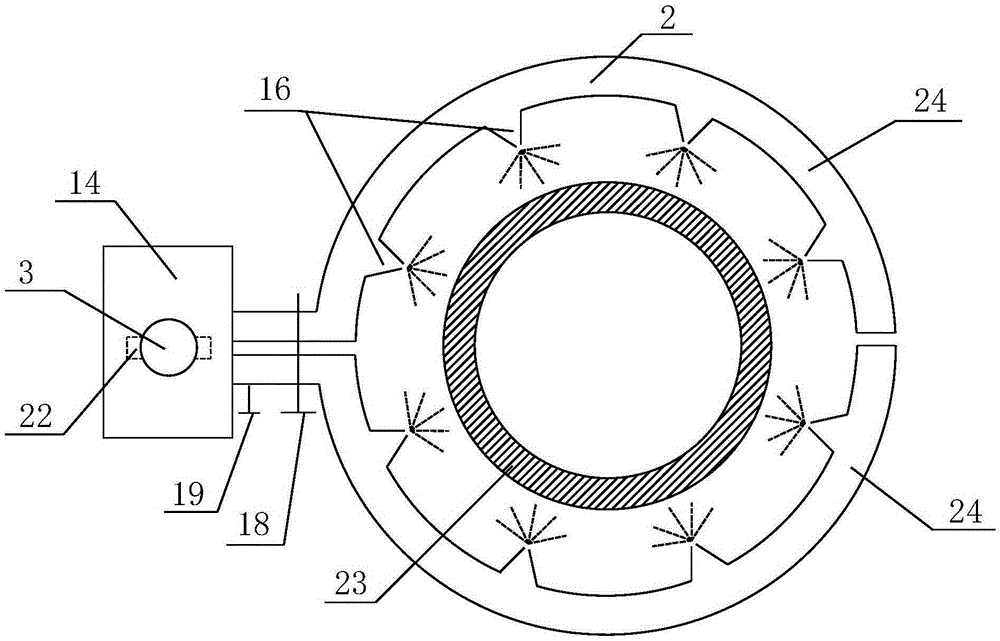

[0031] Such as Figures 1 to 3 As shown, the automatic spraying equipment for the outer wall of the tubular metal heat exchanger according to the present invention is mainly composed of three parts: a paint tank 1 , a spray head 2 and a vertical pole 3 .

[0032] Inorganic non-metallic paint is housed in paint tank 1, and circular top cover 7 is arranged on paint tank 1, and feed port 9 is opened on top cover 7, and described feed port 9 communicates with atmosphere; Top cover 7 is also provided with The mixer 8, the blades of the mixer 8 go deep into the paint, and are used to stir the paint evenly.

[0033] The nozzle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com