Paste for light receiving surface electrode of solar cell, manufacturing method and solar cell unit

A light-receiving surface electrode and solar cell technology, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of reducing contact resistance, weak substrate erosion, etc., and achieve low contact resistance, high bonding strength, and high output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. Furthermore, in the following embodiments, the drawings are appropriately simplified or deformed, and the dimensional ratios, shapes, and the like of each part are not necessarily drawn correctly.

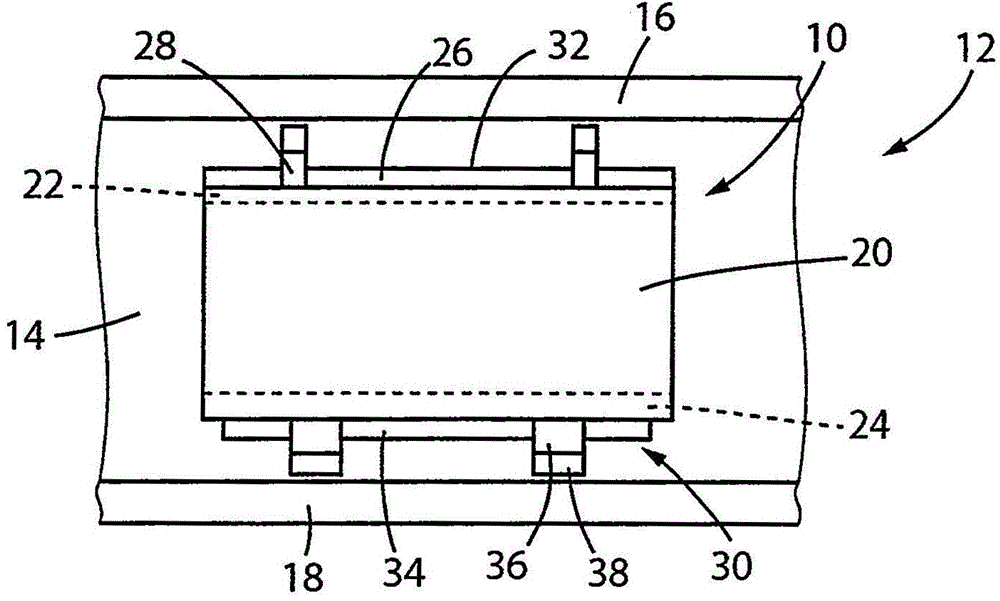

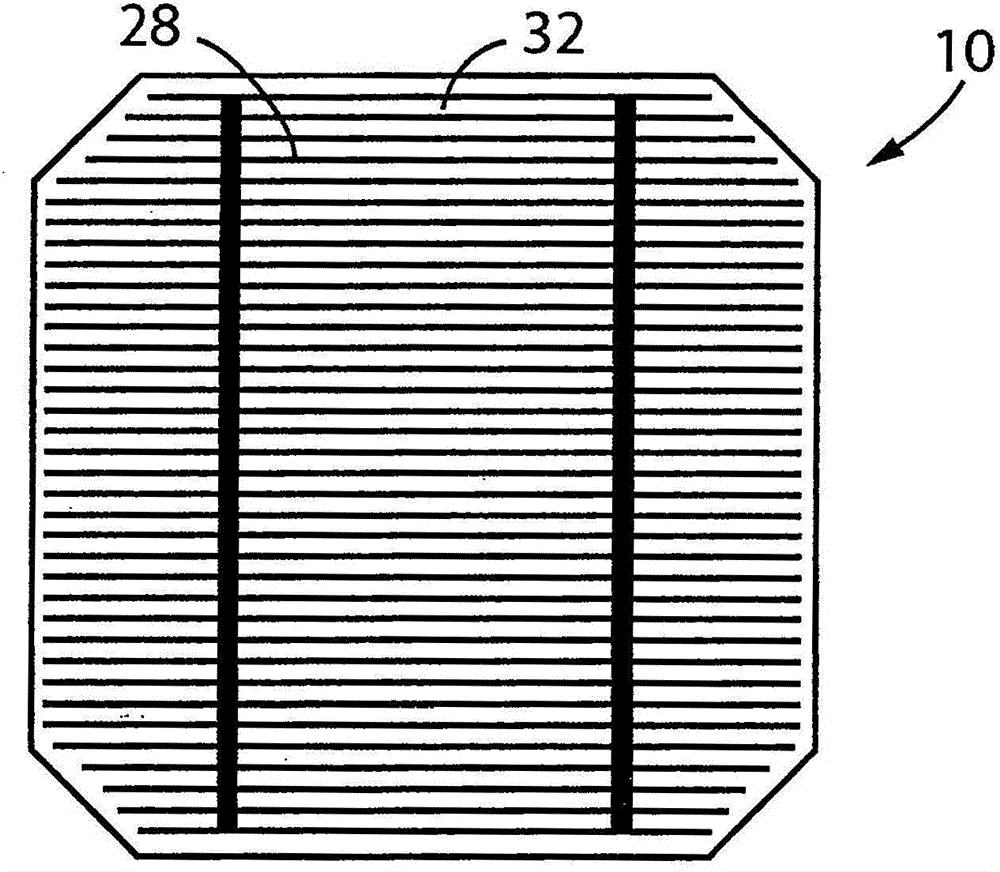

[0068] figure 1 It is a figure which schematically shows the cross-sectional structure of the solar cell module 12 provided with the silicon-based solar cell 10 to which the electroconductive composition of one Example of this invention was applied. exist figure 1 Among them, the solar cell module 12 includes the solar cell 10 described above, a sealing material 14 for sealing it, a surface glass 16 provided on the sealing material 14 on the light-receiving surface side, and a surface glass 16 provided to protect the solar cell 10 and the sealing material 14 from the back side. The protective film (ie back plate) 18. The sealing material 14 is, for example, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com