Circulating filtration type nuclear pore membrane etching device

A circulating filtration and etching device technology, applied in the preparation of test samples, etc., can solve problems such as film rolling machine transmission failure, etching solution concentration changes, etching speed changes, etc., to ensure temperature control accuracy, liquid preparation operation is convenient, The effect of improving the uniformity of temperature and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

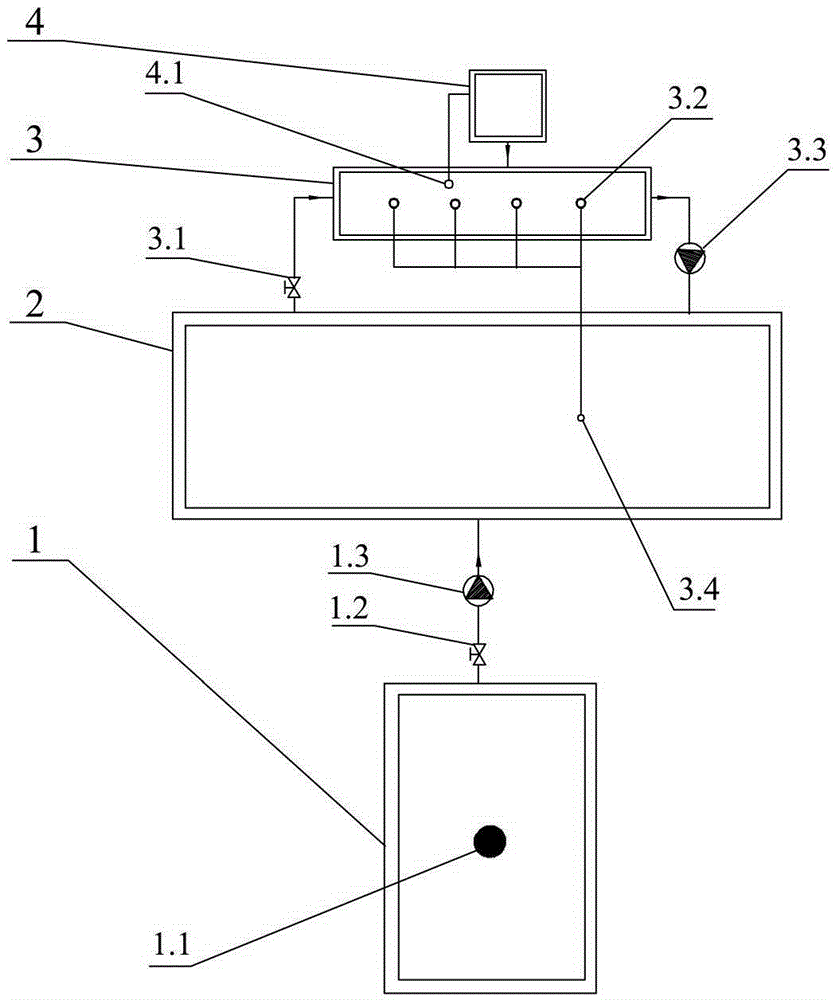

[0025] Example 1: see figure 1 , a circulating filter type nuclear pore membrane etching device. The device mainly includes a liquid distribution tank 1, an etching tank 2, a heating tank 3, and a liquid replacement tank 4. The pipeline of etching tank 2 is connected to the input port of heating tank 3, and the pipeline is provided with waterway switch 3.1; the output of heating tank 3 is connected to etching tank 2 through circulating filter 3.3, and heater 3.2 is arranged in heating tank 3, and heater 3.2 monitors etching The thermal probe 3.4 of the liquid temperature is arranged in the etching tank 2; the agitator 1.1 is arranged in the liquid distribution tank 1, and the liquid distribution tank 1 is connected to the etching tank 2 through the water circuit switch 1.1 and the liquid adding filter 1.2; There is a concentration probe 4.1 for monitoring the concentration in the heating tank 3, and the replenishment tank automatically supplies etching solution to the etching...

Embodiment 2

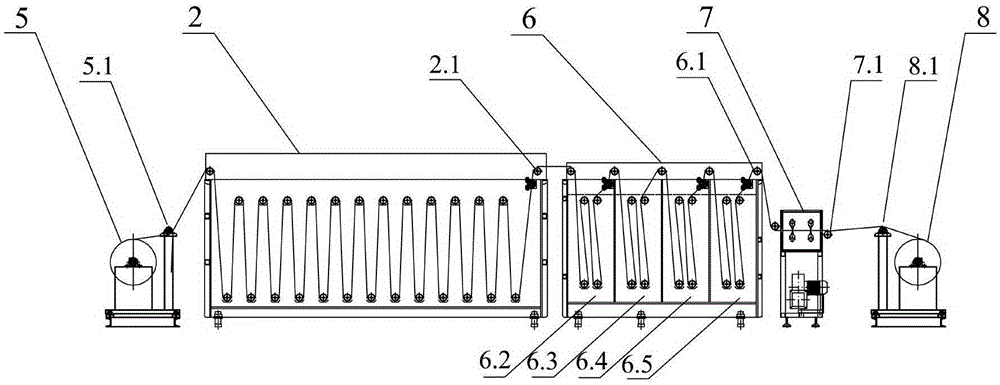

[0026] Example 2: see figure 2 , a circulating filter type nuclear pore membrane etching device. The film transmission mechanism includes an unwinder 5, an etching tank 2, a cleaning machine 6, a dryer 7 and a winder 8 which are arranged in sequence, and the unwinder 1 is provided with an unwinding reel 1.1 of the nuclear pore membrane; The etching tank 2 is provided with an etching pressure roller 2.1 for transporting the nuclear pore membrane, and the cleaning machine 3 is provided with a cleaning pressure roller 6.1 for conveying the nuclear pore membrane; the drying machine 7 is provided with a drying pressure roller for conveying the nuclear pore membrane 7.1; The winding press roller 8.1 of the nuclear pore membrane is provided on the winding machine 8 . The cleaning machine 6 is sequentially provided with an acid-base neutralization tank 6.2, a first washing tank 6.3, a second washing tank 6.4 and an ultrasonic cleaning tank 6.5 which are not connected to each other. ...

Embodiment 3

[0035] Embodiment 3: see figure 1 and figure 2 , a circulating filter type nuclear pore membrane etching device. The device mainly includes a film etching mechanism and a film driving mechanism. The film etching mechanism includes a liquid distribution tank 1 , an etching tank 2 , a heating tank 3 and a liquid replenishing tank 4 . The pipeline of etching tank 2 is connected to the input port of heating tank 3, and the pipeline is provided with waterway switch 3.1; the output of heating tank 3 is connected to etching tank 2 through circulating filter 3.3, and heater 3.2 is arranged in heating tank 3, and heater 3.2 monitors etching The thermal probe 3.4 of the liquid temperature is arranged in the etching tank 2; the agitator 1.1 is arranged in the liquid distribution tank 1, and the liquid distribution tank 1 is connected to the etching tank 2 through the water circuit switch 1.1 and the liquid adding filter 1.2; There is a concentration probe 4.1 for monitoring the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com