A quick release steam trap

A steam trap and unlocking technology, applied in steam traps, mechanical equipment, etc., can solve the problems of valve disc partial seating and erosion, and achieve the effect of improving the lifting force, high parameters, and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

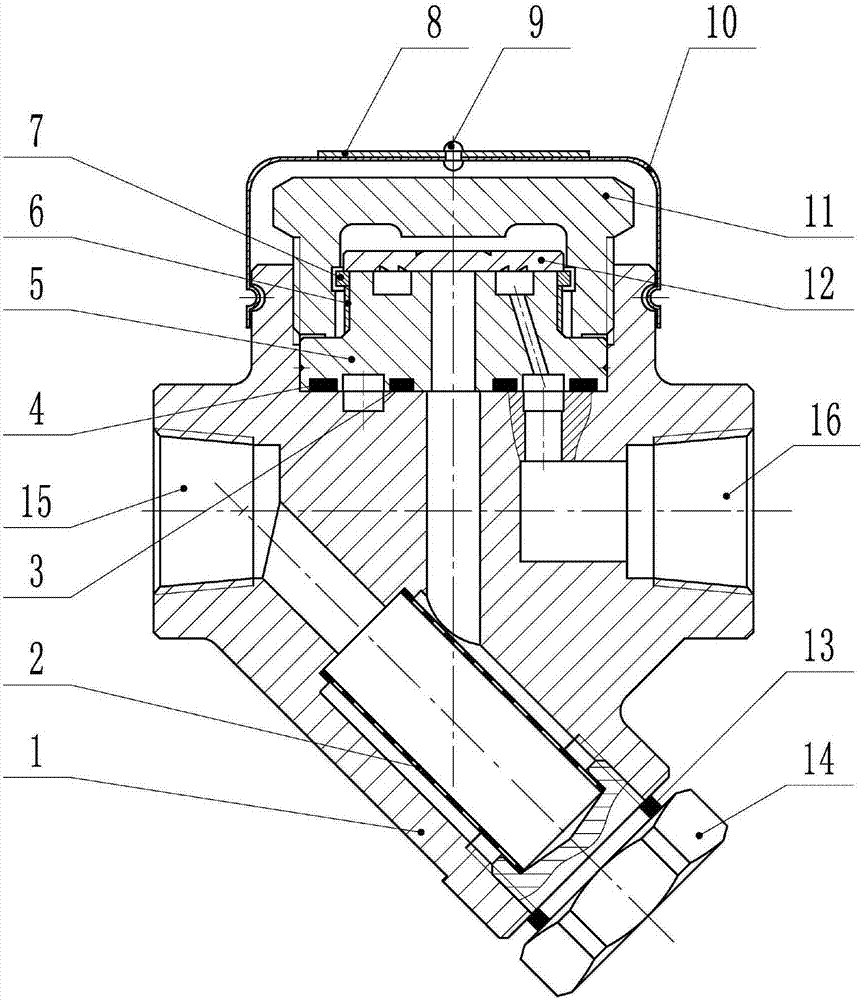

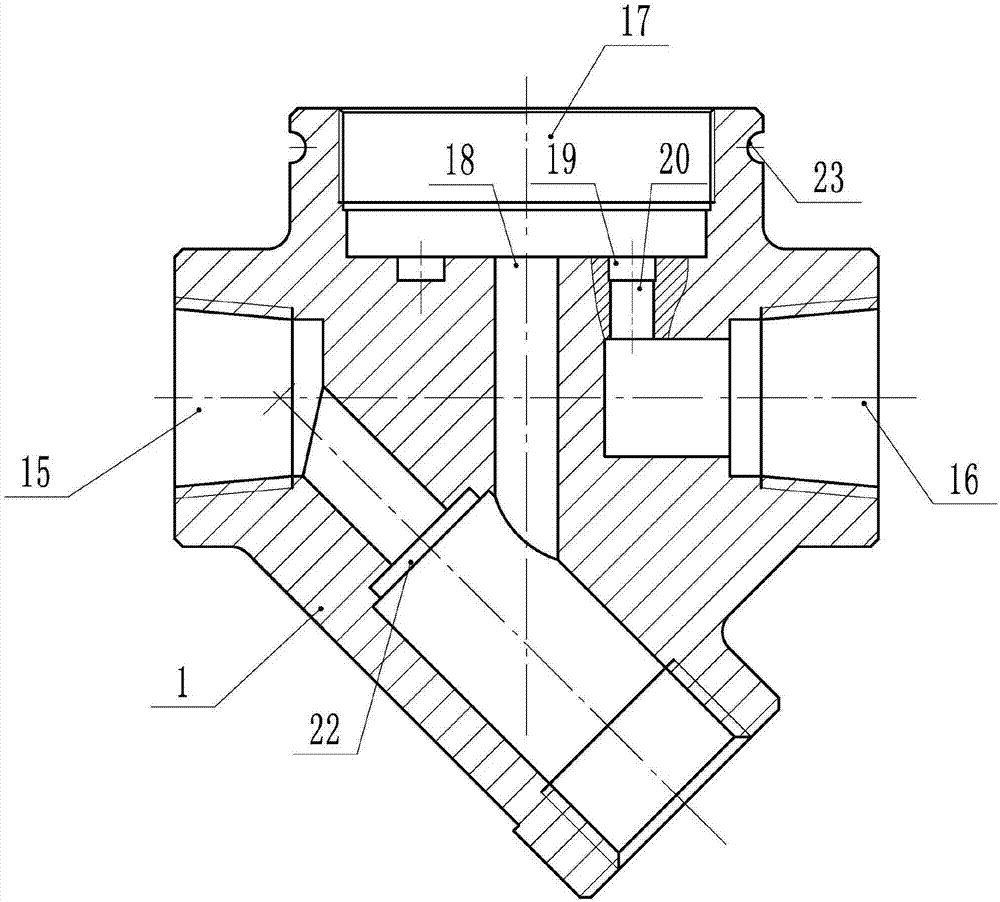

[0037] exist image 3 , 4 , 5 middle: Y-shaped valve body 1 is provided with water inlet 15 on the left side, and its right side is provided with water outlet 16 . The side of the upper end of the Y-shaped valve body 1 is provided with a semi-circular groove 23, and the upper end of the Y-shaped valve body 1 on both sides of the center line perpendicular to the center line of the water inlet 15 and the water outlet 16 is symmetrically provided with a semi-circular groove I36, a semi-circular groove Groove II 37, the upper side of the Y-shaped valve body 1 is provided with a semi-circular groove 23, the upper end of the Y-shaped valve body 1 has a semi-circular groove Ⅰ36, and the semi-circular groove II 37 communicates with the semi-circular groove 23; the upper end of the Y-shaped valve body 1 is provided with a cavity Body 17, in the middle of the bottom surface of the cavity 17 is provided with a water inlet hole I18, and an annular water tank I19 is provided, and a draina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com