Design method of a bell-shaped water inlet channel

A technology for a water inlet channel and a design method, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc. Auxiliary design, instability of pump station operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

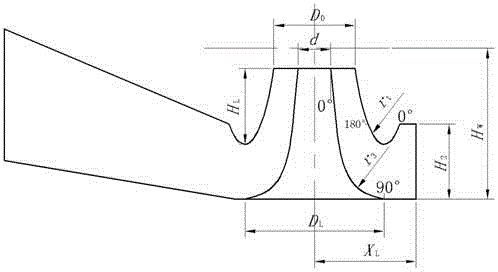

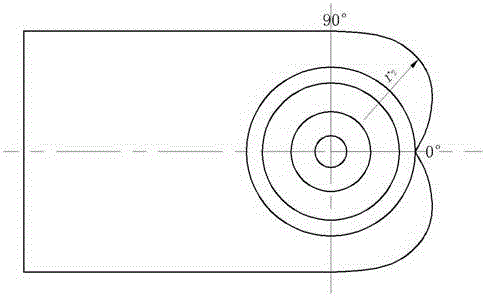

[0069] The present invention determines the rear wall distance X of the suction chamber of the water inlet channel through the following formulas T , horn tube diameter D L, the diameter of the diversion cone top circle d, the height of the suction chamber H 2 , Horn tube height H L , runner height H W , the radius of the bell-shaped curve of the bell-shaped turning section r 1 , Bell-shaped turning section plane volute curve radius r 2 , The curve radius r of the bell-shaped turning section water guiding circular table 3 Wait for a few parameters.

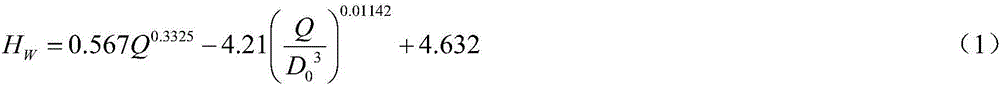

[0070] This embodiment is at a given impeller inlet diameter D 0 , flow Q in design working conditions, speed n, and calculate the main parameters of the bell-shaped water inlet channel:

[0071]

[0072] h 2 =0.7143·H W 0.9789 (2)

[0073] h L =0.4285H W 0.9781 (3)

[0074] D. L =H 2 +0.5H L +0.071H W (4)

[0075] x T =H 2 0.979 +0.5H L 0.9878 +0.00081H W 0.0001015 (5)

[0076]

[0077]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com