FDT modular double-probe formation tester and test system

A formation tester and testing system technology, applied in the field of oil and gas exploration, can solve the problem that the horizontal permeability, vertical permeability and storage coefficient formation pressure gradient of the formation cannot be measured, and the anisotropic formation permeability and pressure cannot be synchronized at the same time. It cannot truly reflect the real characteristics of the formation and the nature of the reservoir, and achieve the effect of solving the permeability and pressure test, compact structure and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

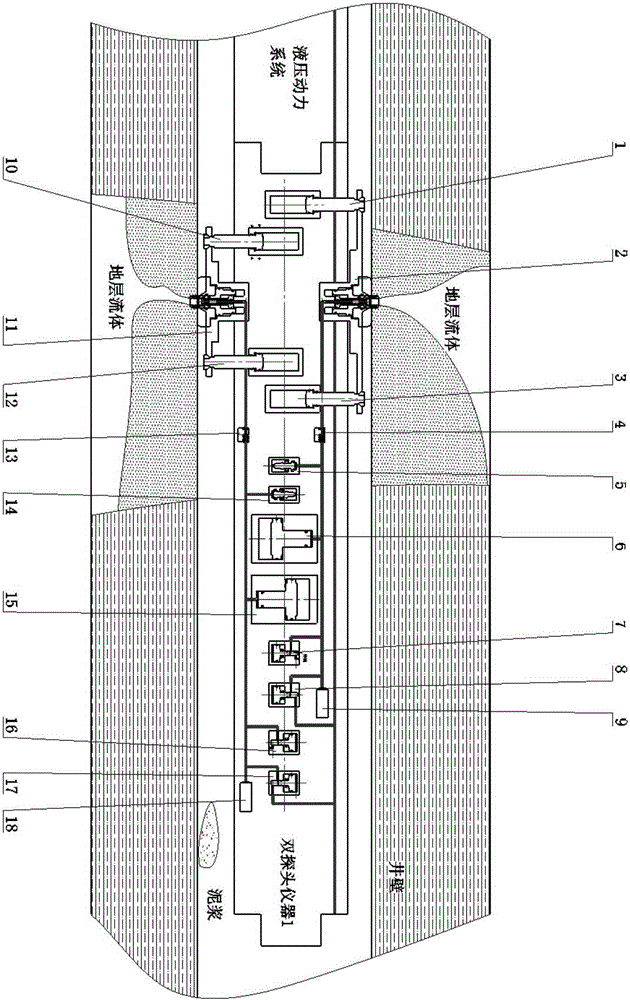

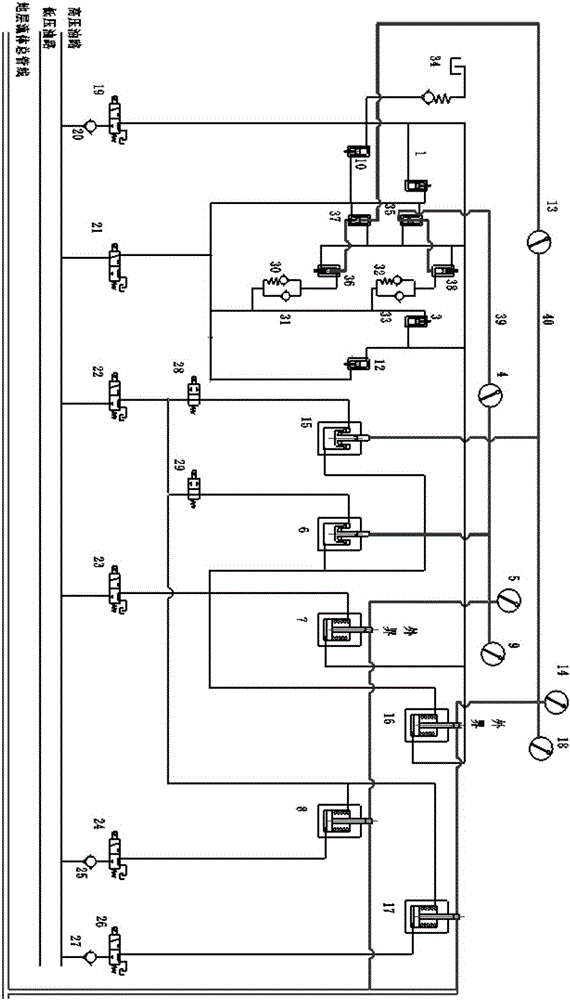

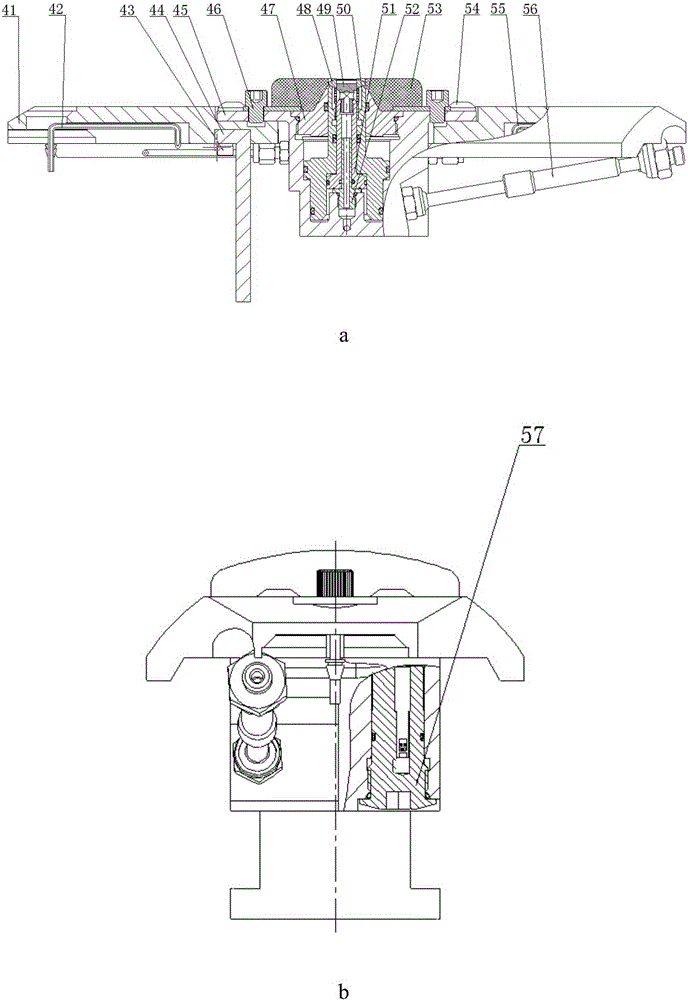

[0033] A kind of FDT modular dual-probe formation tester of the present invention, as figure 1 As shown, it includes five parts: the main body of the tester, the first probe 2 and the second probe 11, the hydraulic power system, and the formation fluid testing system inside the main body of the tester; the main body of the tester is preferably a cylindrical solid structure of titanium alloy, and the formation fluid All components in the test system and hydraulic power system are installed on the main body of the tester. The main body of the tester is distributed with formation fluid pipelines, probe fluid pipelines and hydraulic oil pipelines, respectively connecting the formation fluid test system and hydraulic power system into one ; The upper and lower interfaces of the main body of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com