Wastewater utilization device

A technology for waste water and waste water tanks, which is applied in water supply installations, water supply installations, industrial water supply conservation, etc., can solve problems such as failure to realize uninterrupted water supply and waste water utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

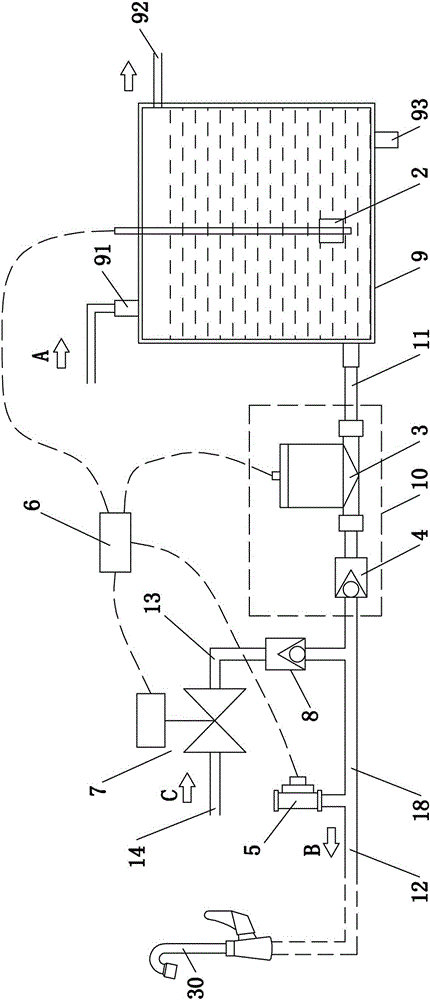

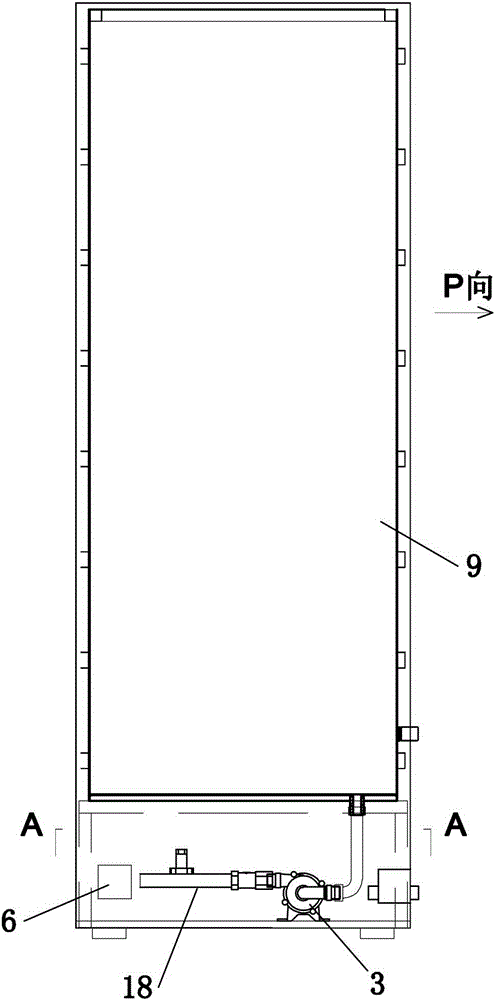

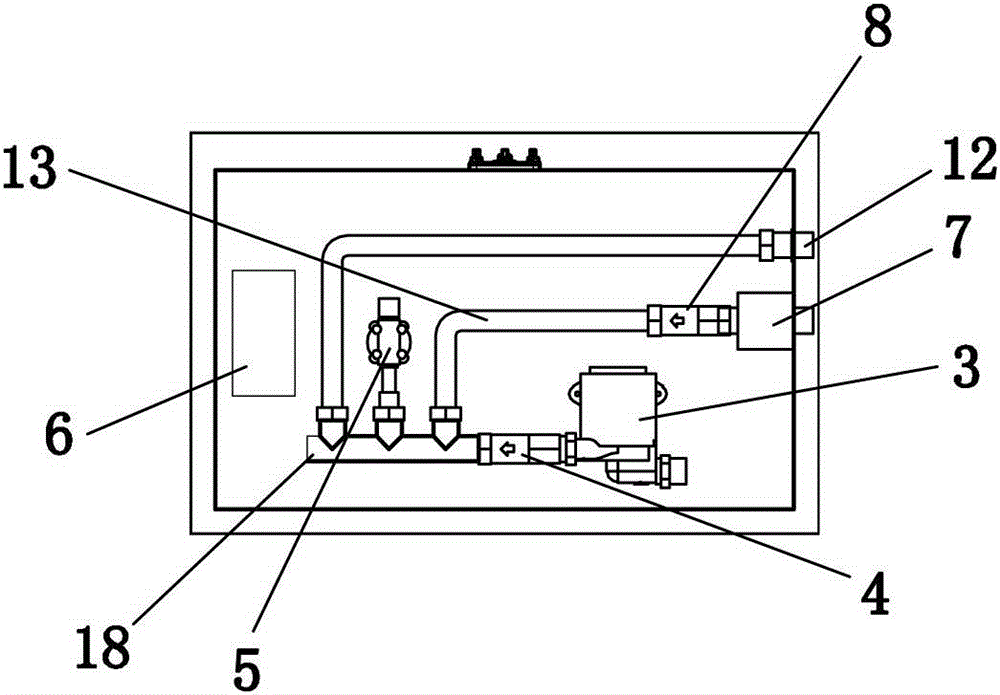

[0033] Embodiment one, see Figure 1 to Figure 4 As shown, a waste water utilization device includes a waste water channel 18, a waste water tank 9, a water replenishment channel 13, a water sensor 5, a water shortage sensor 2 and an electric control device 6, and the waste water channel 18 is provided with a water inlet 11, a waste water pump The assembly 10 and the water outlet 12, the water inlet 11 communicate with the waste water tank 9, the waste water tank 9 is provided with a waste water collection port 91, and the replenishment channel 13 bypasses the waste water channel 18 connected between the water outlet 12 and the waste water pump assembly 10 on, and the water supply channel 13 is provided with a water supply electromagnetic valve 7; the water sensor 5 is provided on the waste water channel 18 between the water outlet 12 and the waste water pump assembly 10, and the water shortage sensor 2 is a float switch (also can be water level electrode, or water flow sensor...

Embodiment 2

[0044] Embodiment two, such as Figure 5 As shown, it is similar to Embodiment 1, and the difference has the following three points: first: the water shortage sensor 2 is a water flow sensor or a water pressure sensor or a float switch or an electrode, which is arranged on the waste water pump assembly On the waste water channel 18 before 10, since the front section of the waste water channel 18 is connected with the waste water tank 9, the water shortage sensor 2 will monitor the water pressure or the change of the water flow signal of the water passing through in real time, as the water level in the waste water tank 9. Change the real situation so that the water shortage sensor 2 can monitor whether the waste water tank 9 is short of water in time. When the water shortage is detected, the waste water pump assembly 10 stops working, and simultaneously transmits the water shortage signal to the electric control device 6, and the electric control device 6 Control the replenishm...

Embodiment 3

[0045] Embodiment three, such as Figure 6 As shown, it is similar to Embodiment 1 and Embodiment 2, and its special feature is that the water replenishment solenoid valve 7 adopts a solenoid valve body that can prevent backflow, so that the use of a water replenishment check valve can be saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com