Fruit vinegar filter system

A filtration system and fruit vinegar technology, applied in the field of filtration systems, can solve the problems of dead-end filtration, secondary precipitation of products, and high use costs, and achieve the effects of convenient regeneration and recovery, shortened production cycle, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment the present invention is described in further detail:

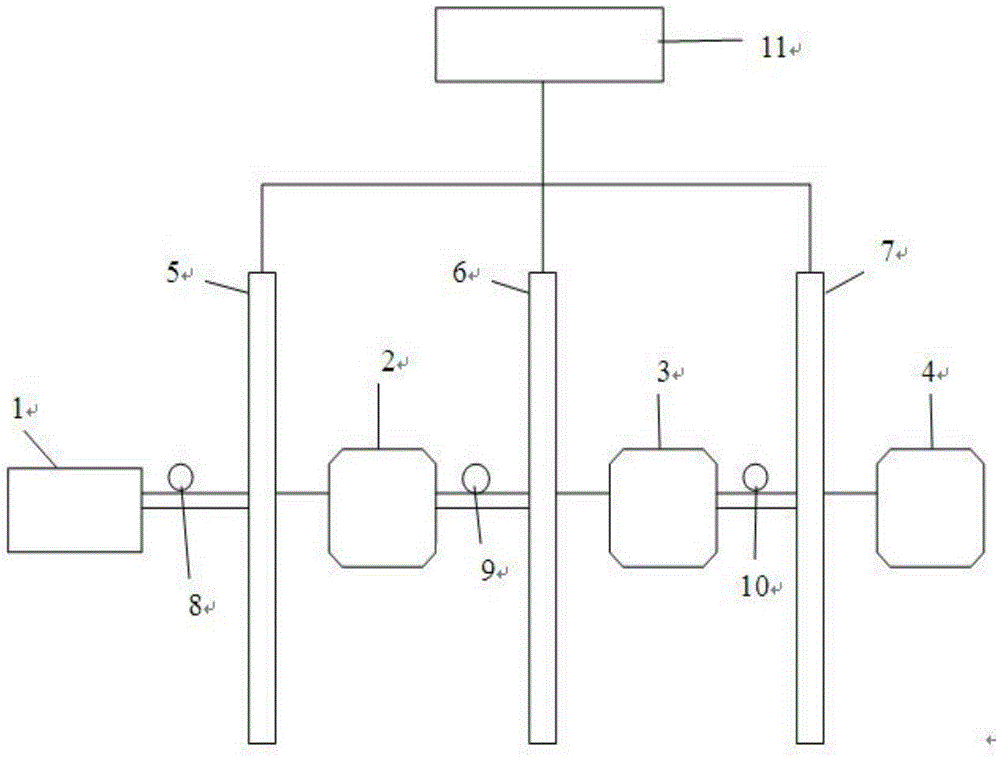

[0027] The invention discloses a fruit vinegar filtering system, which is characterized in that it comprises:

[0028] Fruit vinegar supply tank 1, which is used to hold unfiltered fruit vinegar;

[0029] The first pipeline communicates with the fruit vinegar supply tank 1, and a solenoid valve is arranged on the first pipeline;

[0030] Tetrafluoroethylene membrane filtration device 5, which includes a tetrafluoroethylene membrane and is connected to the first pipeline, the pore size of the tetrafluoroethylene membrane is between 0.01 μm and 15 μm;

[0031] The first pressure pump 8, which communicates with the first pipeline, pumps the fruit vinegar in the first pipeline to the tetrafluoroethylene membrane device 5 to filter;

[0032] The first filter tank 2 is configured to accommodate the fruit vinegar filtered through the tetrafluoroethylene membrane filter devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com