A method for ultra-deep hydrodesulfurization of diesel oil

A deep hydrogenation and diesel oil technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of not meeting the product chromaticity index at the same time, so as to save investment and operating costs, reduce usage, and avoid The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

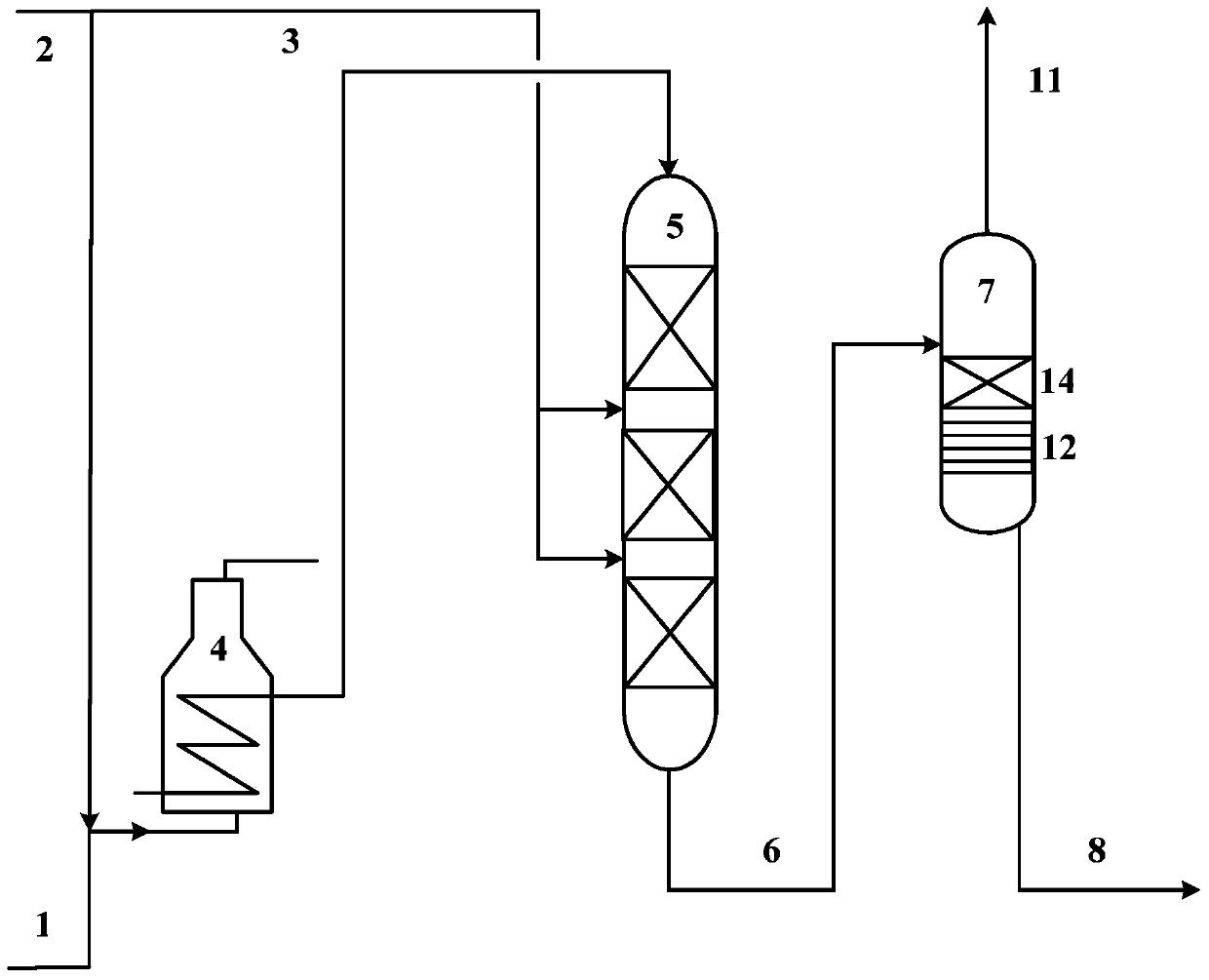

Image

Examples

Embodiment 1

[0038] Raw material oil A and hydrogen enter the reactor equipped with hydrogenation catalyst C together, and the volume ratio of hydrogen to oil is 300Nm 3 / m 3 , under the action of hydrogenation catalyst C, the deep hydrodesulfurization reaction is carried out, the reaction conditions are: reaction temperature 380 ℃, raw material oil liquid hourly volume space velocity 3.0h -1 , the pressure of the reaction system is 6.0 MPa, and the sulfur content of the liquid phase stream in the obtained reactor effluent is less than 10 μg / g.

[0039] The middle part of the hot high-pressure separator is filled with hydrogenation catalyst D, and the effluent from the reactor enters the hot high-pressure separator from the middle and upper part of the hot high-pressure separator through heat exchange, and passes through the catalyst bed packed in the hot high-pressure separator from top to bottom. The temperature of the separator is 300°C, the pressure is 6.0MPa, and the liquid hourly vo...

Embodiment 2

[0041] Raw material oil B and hydrogen enter the reactor equipped with hydrogenation catalyst C together, and the volume ratio of hydrogen to oil is 500Nm 3 / m 3 , under the action of hydrogenation catalyst C, carry out deep hydrodesulfurization reaction, etc., the reaction conditions are: reaction temperature 390 ℃, raw material oil liquid hourly volume space velocity 2.0h -1 , the reaction system pressure is 8.0MPa.

[0042] The middle part of the hot high-pressure separator is filled with hydrogenation catalyst C, and the reactor effluent enters the hot high-pressure separator from the bottom of the hot high-pressure separator through heat exchange, and passes through the catalyst bed packed in the hot high-pressure separator from bottom to top, and the hot high-pressure The temperature of the separator is 270°C, the pressure is 8.0MPa, and the liquid hourly volume space velocity is 18.0h -1 . The liquid phase stream separated by the hot high-pressure separator is cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com