Autocatalysis preparation method of copolymer benzoxazine-resin polymer sphere and autocatalysis preparation method of resin-based carbon sphere

A technology of benzoxazine and polymer balls, applied in the field of polymers, can solve the problems of low monodispersity, complicated synthesis steps and post-processing, and small particle size range of resin balls and carbon balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a self-catalyzed preparation method of copolymerized benzoxazine-resin polymer spheres, comprising the following steps:

[0040] dissolving m-aminophenol and formaldehyde in a solvent, and obtaining copolymerized benzoxazine-resin polymer balls after polymerization;

[0041] The solvent is a mixed solution of water and alcohol compounds.

[0042] In the present invention, m-aminophenol and formaldehyde are firstly dissolved in a solvent to obtain a mixed solution, and no external catalyst is added in the process. In the present invention, there is no special limitation on the order in which m-aminophenol and formaldehyde are dissolved in the solvent, and the technical solution for preparing phenolic resin well known to those skilled in the art can be used. In the present invention, the m-aminophenol is preferably firstly added to the solvent, and then formaldehyde is added thereto to obtain a mixed solution. After the formaldehyde is added, m-am...

Embodiment 1

[0062] Add 73.33 mg of m-aminophenol to a mixed solution of 8.4 mL of water and 8.4 mL of methanol, stir and dissolve at 30°C for 10 minutes, then add 121 μL of formaldehyde, stir for 1 hour, then raise the temperature of the water bath to 75°C , and continued to stir for 4 hours. The obtained reaction product was centrifuged at 8000 rpm for 5 minutes, the centrifuged solid was washed twice with water, and dried at 80° C. for 12 hours to obtain copolymerized benzoxazine-resin polymer balls.

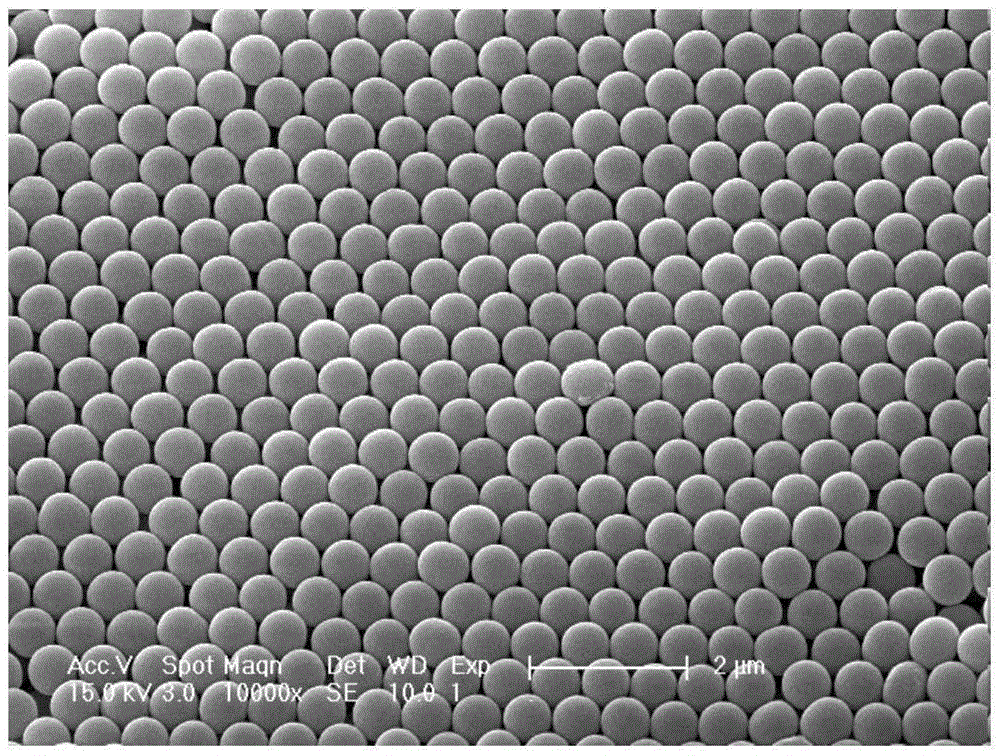

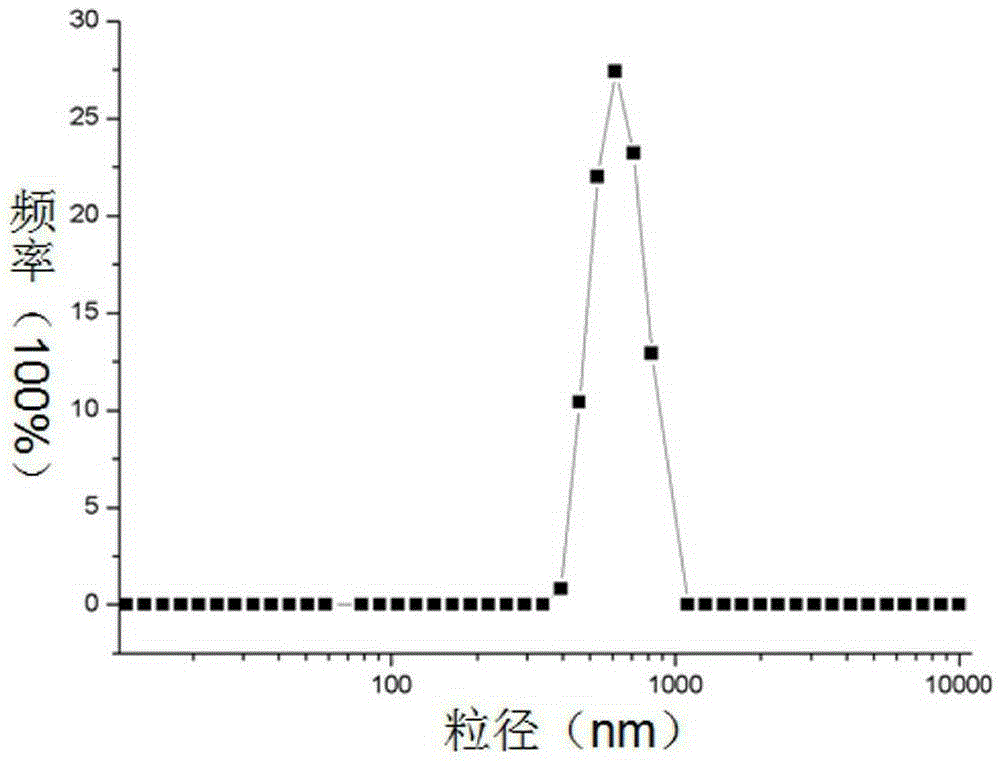

[0063] The present invention carries out scanning electron microscope scanning analysis to the obtained copolymerized benzoxazine-resin polymer ball, and the result is as follows figure 1 as shown, figure 1 The scanning electron micrograph of the copolymerized benzoxazine-resin polymer sphere prepared for Example 1 of the present invention is obtained by figure 1 It can be seen that the phenolic resin balls prepared by the present invention have high monodispersity. The present inventi...

Embodiment 2

[0065] Add 73.33 mg of m-aminophenol to a mixed solution of 8.4 mL of water and 8.4 mL of methanol, stir and dissolve at 20°C for 10 minutes, then add 121 μL of formaldehyde, stir for 1 hour, then raise the temperature of the water bath to 75°C , and continued to stir for 4 hours. The obtained reaction product was centrifuged at 8000 rpm for 5 minutes, washed twice with centrifuged water, and then dried at 80° C. for 12 hours to obtain copolymerized benzoxazine-resin polymer balls.

[0066] The present invention carries out scanning electron microscope scanning analysis to the obtained copolymerized benzoxazine-resin polymer ball, and the result is as follows Figure 8 as shown, Figure 8 The scanning electron micrograph of the copolymerized benzoxazine-resin polymer sphere prepared for Example 2 of the present invention is obtained by Figure 8 It can be seen that the phenolic resin balls prepared by the present invention have high monodispersity. The particle diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com