A C40 pumped concrete with a heat resistance of 500°C

A technology for pumping concrete and concrete, which is applied in the field of building materials, can solve the problems that concrete cannot be pumped, unstable price, unsuitable, etc., to solve the problems of pumpability and constructability, good pumpability, and stable source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below we will further elaborate on the C40 pumped concrete with a heat resistance of 500°C of the present invention in combination with specific examples, so as to gain a deeper understanding of the technology of the present invention, but this should not limit the protection scope of the present invention.

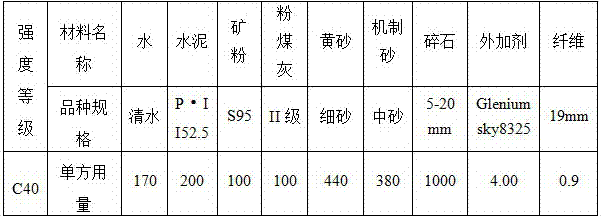

[0017] The invention is a C40 pumping concrete with a heat resistance of 500°C. The concrete should have good pumpability and solve the problems of pumpability and workability of heat-resistant concrete in engineering applications. Heat-resistant concrete has high strength, and concrete raw materials, especially coarse and fine aggregates, are more common and have stable sources. In the C40 concrete of the present invention, its composition and unilateral dosage ratio (kg / m 3 )as follows:

[0018] Cement 200~220, fly ash 80~100, slag powder 100~120, natural fine sand with a fineness modulus of 1.8~2.0 420~460, andesite machine-made sand 360~400, andesite 5-20mm co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com