Preparation method for calcium hydrate loading activated clay

A technology of activated clay and calcium hydroxide, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of poor wastewater treatment, long cycle, instability, etc., achieve short cycle, low production cost, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

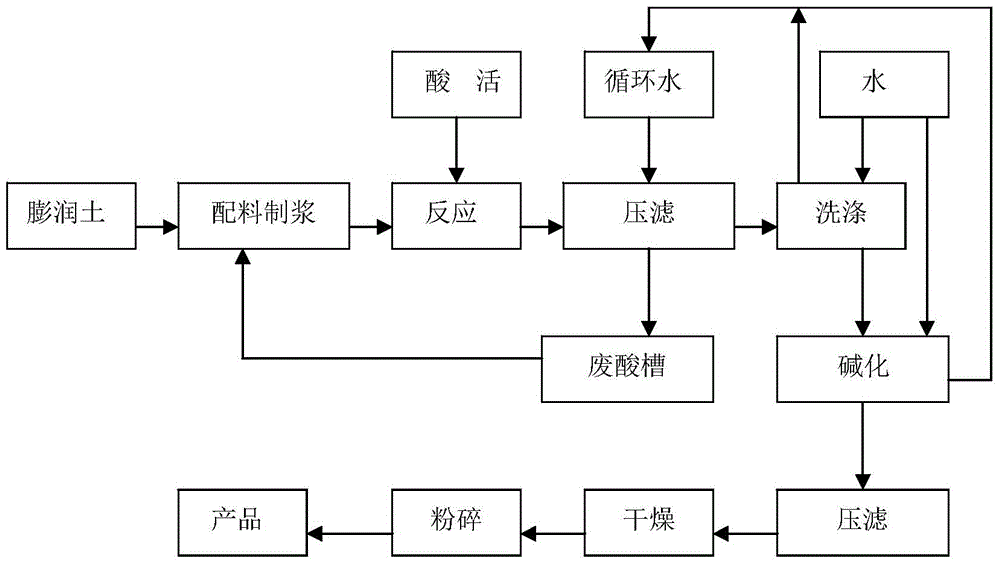

Method used

Image

Examples

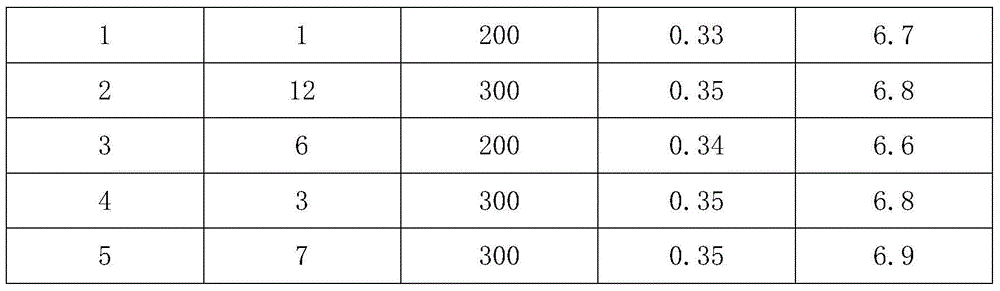

Embodiment 1

[0030] A preparation method of loaded calcium hydroxide activated clay, comprising the following steps:

[0031] S1: Batching pulping: mix bentonite and activated clay mother liquor waste acid with a concentration of 18% in a weight ratio of 1:3 to obtain a slurry material;

[0032] S2: Acid activation reaction: Send the slurry material obtained in step S1 to a heat-resistant and acid-resistant reaction kettle, and then heat it to 95°C with steam, and react continuously for 4 hours at a stirring speed of 30r / min to obtain the reacted slurry material;

[0033] S3: Press filtration for the first time: Use a pump to transport the slurry material reacted in step S2 to a plate and frame filter press, and perform press filtration at a pressure of 0.7 MPa until the water content of the filter cake is 50%;

[0034] S4: Washing and second pressure filtration: add water 3 times the weight of the filter cake obtained in step S3 for stirring and washing, and add polyacrylamide flocculant,...

Embodiment 2

[0040] A preparation method of loaded calcium hydroxide activated clay, comprising the following steps:

[0041] S1: Batching and pulping: mix bentonite and activated clay mother liquor waste acid with a concentration of 22% in a weight ratio of 1:3 to obtain a slurry material;

[0042] S2: Acid activation reaction: Send the slurry material obtained in step S1 to a heat-resistant and acid-resistant reaction kettle, then heat it to 100°C with steam, and react continuously for 3.5 hours at a stirring speed of 40r / min to obtain the reacted slurry material;

[0043] S3: Press filtration for the first time: Use a pump to transport the slurry material reacted in step S2 to a plate and frame filter press, and perform press filtration at a pressure of 1.0 MPa until the water content of the filter cake is 45%;

[0044] S4: Washing and second pressure filtration: add water 6 times the weight of the filter cake obtained in step S3 for stirring and washing, and add polyacrylamide floccula...

Embodiment 3

[0050] A preparation method of loaded calcium hydroxide activated clay, comprising the following steps:

[0051] S1: Batching pulping: mix bentonite and activated clay mother liquor waste acid with a concentration of 20% in a weight ratio of 1:3 to obtain a slurry material;

[0052] S2: Acid activation reaction: Send the slurry material obtained in step S1 to a heat-resistant and acid-resistant reaction kettle, then heat it to 97°C with steam, and react continuously for 3.7 hours at a stirring speed of 35r / min to obtain the reacted slurry material;

[0053] S3: Press filtration for the first time: Use a pump to transport the slurry material after the reaction in step S2 to a plate and frame filter press, and perform press filtration at a pressure of 0.85 MPa until the water content of the filter cake is 47%;

[0054] S4: Washing and second pressure filtration: add water 4.5 times the weight of the filter cake obtained in step S3 for stirring and washing, and add polyacrylamide f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com