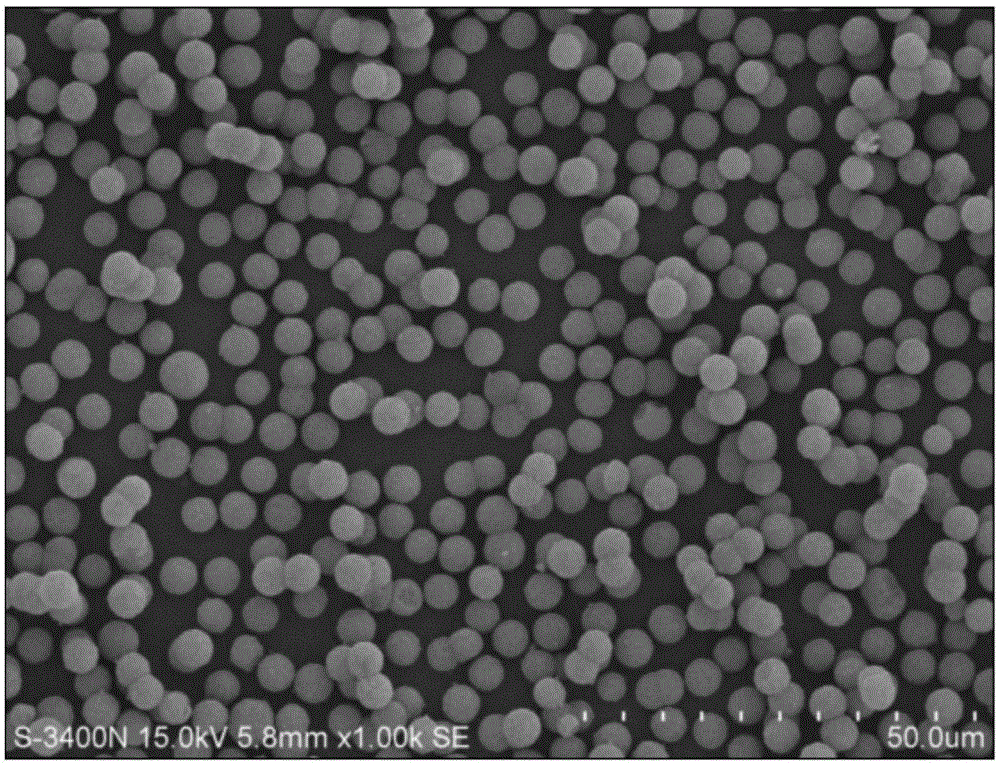

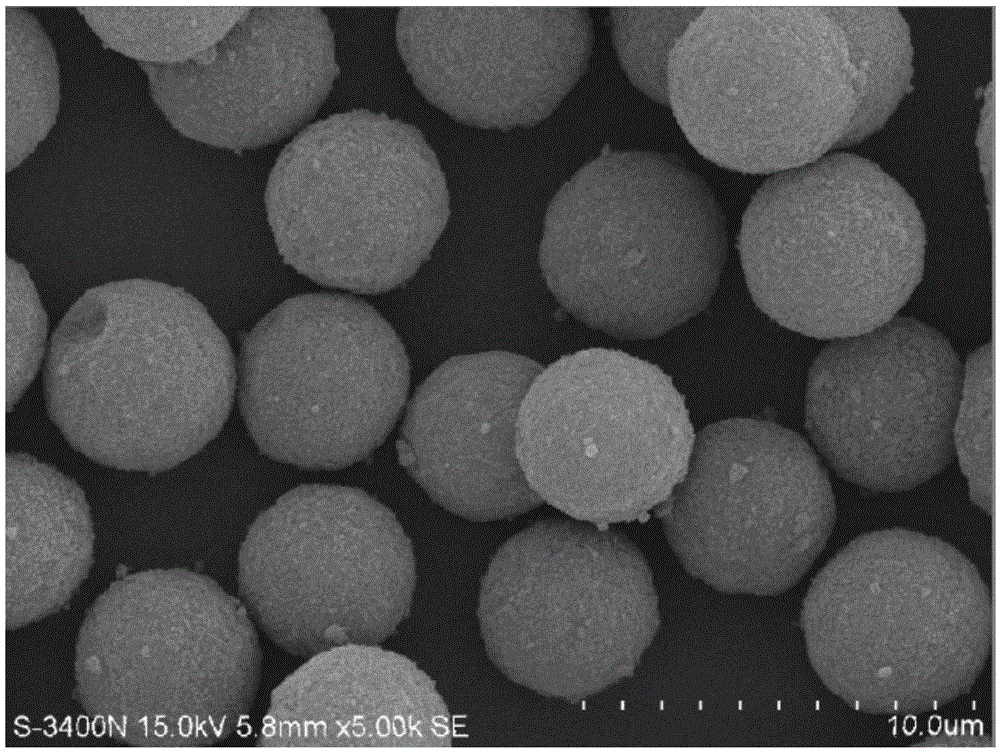

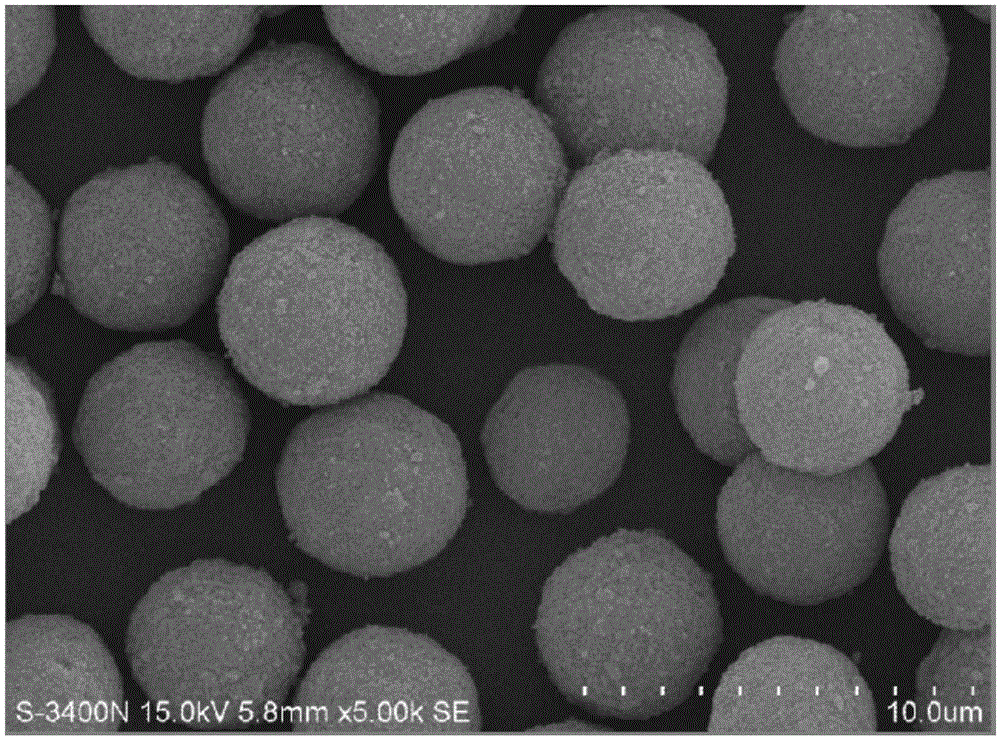

Monodisperse mesoporous silica microsphere powder and preparation method thereof

A technology of mesoporous silica and microsphere powder, applied in the direction of silica, silicon oxide, etc., can solve the problems of uneven application, affecting slippery feeling, rough surface, etc., achieving smooth spherical surface and low cost of synthetic raw materials , the effect of high oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The specific process of preparing monodisperse mesoporous silica microsphere powder in this example is as follows:

[0058] (1) Weigh 0.05 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir and disperse 0.8 g of cetyl ammonium bromide in 5 g of deionized water, stir and disperse evenly. Mix the two dispersions evenly, and adjust the pH value to 7.5 with an absolute ethanol solution containing a certain concentration of ammonia water.

[0059] (2) Weigh 0.05 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir 13 g of tetraethyl orthosilicate (TEOS) in 25 g of deionized water, stir and disperse evenly. Mix the two dispersions and stir well.

[0060] (3) At room temperature, around 25°C, slowly add the dispersion obtained in step (2) to the dispersion obtained in step (1), stir while adding, and keep the stirring speed at 230r / min until white milky When the turbid liquid appears, stop stirring, keep...

Embodiment 2

[0065] The specific process of preparing monodisperse mesoporous silica microsphere powder in this example is as follows:

[0066] (1) Weigh 0.05 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir and disperse 0.8 g of cetyl ammonium bromide in 5 g of deionized water, stir and disperse evenly. Mix the two dispersions evenly, and adjust the pH value to 8.5 with an absolute ethanol solution containing a certain concentration of ammonia water.

[0067] (2) Weigh 0.05 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir 13 g of tetraethyl orthosilicate (TEOS) in 25 g of deionized water, stir and disperse evenly. Mix the two dispersions and stir well.

[0068] (3) At room temperature, around 25°C, slowly add the dispersion obtained in step (2) to the dispersion obtained in step (1), stir while adding, and keep the stirring speed at 100r / min until white milky When the turbid liquid appeared, the stirring was s...

Embodiment 3

[0073] The specific process of preparing monodisperse mesoporous silica microsphere powder in this example is as follows:

[0074] (1) Weigh 0.10 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir and disperse 0.8 g of cetyl ammonium bromide in 5 g of deionized water, stir and disperse evenly. Mix the two dispersions evenly, and adjust the pH value to 7.5 with an absolute ethanol solution containing a certain concentration of ammonia water.

[0075] (2) Weigh 0.10 g of carboxymethyl cellulose in 16 g of deionized water, stir and disperse evenly; stir 13 g of tetraethyl orthosilicate (TEOS) in 25 g of deionized water, stir and disperse evenly. Mix the two dispersions and stir well.

[0076] (3) Control the temperature at about 35°C, slowly add the dispersion obtained in the above step (2) into the dispersion obtained in step (1), stir while adding, and keep the stirring speed at 100r / min until it becomes white and milky Liquid appears, sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com