Super carbon nanodots with strong near-infrared absorption and its preparation method and application

A carbon nanodot, near-infrared technology, applied in the fields of nanotechnology, nanocarbon, and nanotechnology for materials and surface science, can solve the problems of low photothermal conversion efficiency and low absorption, and improve photothermal conversion performance. , The effect of high biocompatibility and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

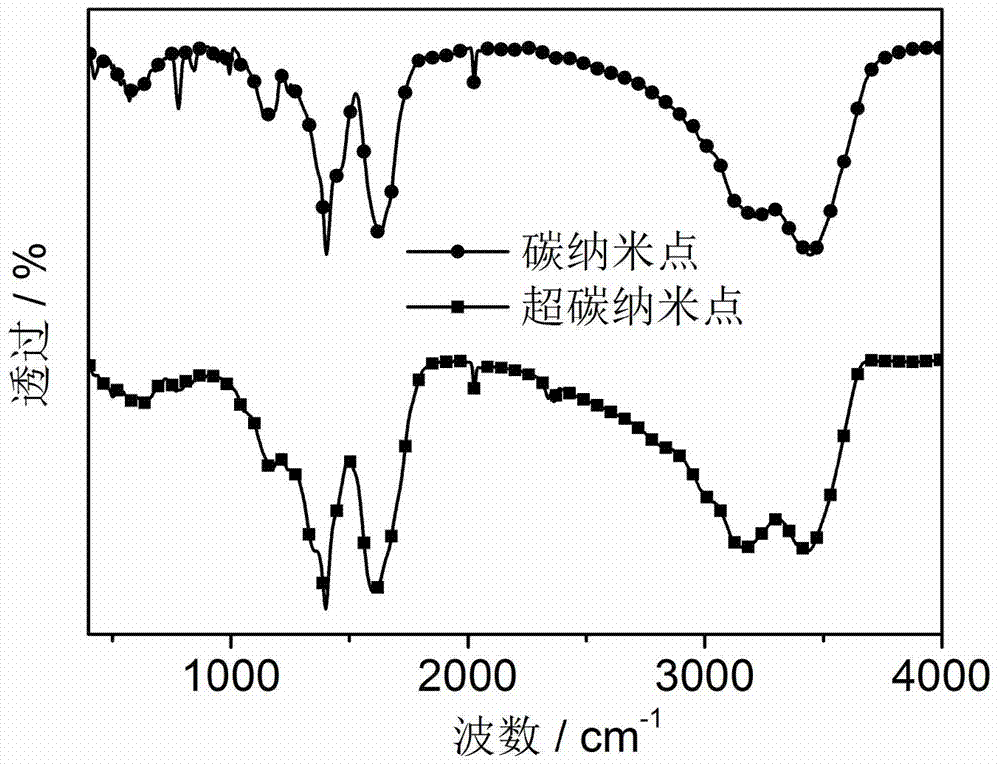

[0052] combine Figure 1-6 Illustrative Example 1

[0053] Super carbon nano-dots with strong near-infrared absorption, the absorption peak is 700nm, assembled by carbon nano-dots, the surface of the carbon nano-dots has amino and pyrrolyl electropositive groups, and also has pyridyl and carboxyl groups and the electronegative group of the hydroxyl group.

[0054] The preparation method of the above-mentioned super carbon nano-dots with strong near-infrared absorption:

[0055] Dissolve citric acid and urea in deionized water at a mass ratio of 1:2 to obtain a transparent solution, place it in a 50ml polytetrafluoroethylene autoclave, react at 160°C for 4h, and freeze-dry the reacted solution at -40°C to obtain Yellow carbon nano dot powder.

[0056] Put the yellow carbon nano-dot powder in a beaker and place it in an environment with a relative humidity of 60% for 14 days. The carbon nano-dots self-assemble under the action of water molecules, and the surface becomes compl...

Embodiment 2

[0063] Super carbon nano-dots with strong near-infrared absorption, the absorption peak is 714nm, assembled by carbon nano-dots, the surface of the carbon nano-dots has electropositive groups of amino and pyrrolyl groups, and also has pyridyl and carboxyl groups and the electronegative group of the hydroxyl group.

[0064] The preparation method of the above-mentioned super carbon nano-dots with strong near-infrared absorption:

[0065] Dissolve citric acid and urea in deionized water at a mass ratio of 1:2 to obtain a transparent solution, place it in a 50ml polytetrafluoroethylene autoclave, react at 160°C for 4h, and freeze-dry the reacted solution at -40°C to obtain Yellow carbon nano dot powder.

[0066] Put the yellow carbon nano-dot powder in a beaker filled with ethanol, then place the beaker in an airtight container filled with water, and place it at 35°C for 20 days. After the water volatilizes, it enters the ethanol. The carbon nano-dots are under the action of wat...

Embodiment 3

[0068] Super carbon nano-dots with strong near-infrared absorption, the absorption peak is 680nm, assembled by carbon nano-dots, the surface of the carbon nano-dots has electropositive groups of amino and pyrrolyl groups, and also has pyridyl and carboxyl groups and the electronegative group of the hydroxyl group.

[0069] The preparation method of the above-mentioned super carbon nano-dots with strong near-infrared absorption:

[0070] Dissolve citric acid and urea in deionized water at a mass ratio of 1:2 to obtain a transparent solution, place it in a 50ml polytetrafluoroethylene autoclave, react at 160°C for 4h, and freeze-dry the reacted solution at -40°C to obtain Yellow carbon nano dot powder.

[0071] Put the yellow carbon nano-dot powder in a beaker and place it in an environment with a relative humidity of 60% for 8 days. The carbon nano-dots self-assemble under the action of water molecules, and the surface becomes completely black. The obtained black solid is disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com