MEMS (Micro Electro Mechanical Systems) electro-thermal actuator and manufacturing process thereof

A manufacturing process and actuator technology, applied in the field of MEMS, can solve the problems of small operating voltage, large working deformation, and fast response of MEMS electrothermal actuators, and achieve the effect of avoiding signal voltage interference, large deformation, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

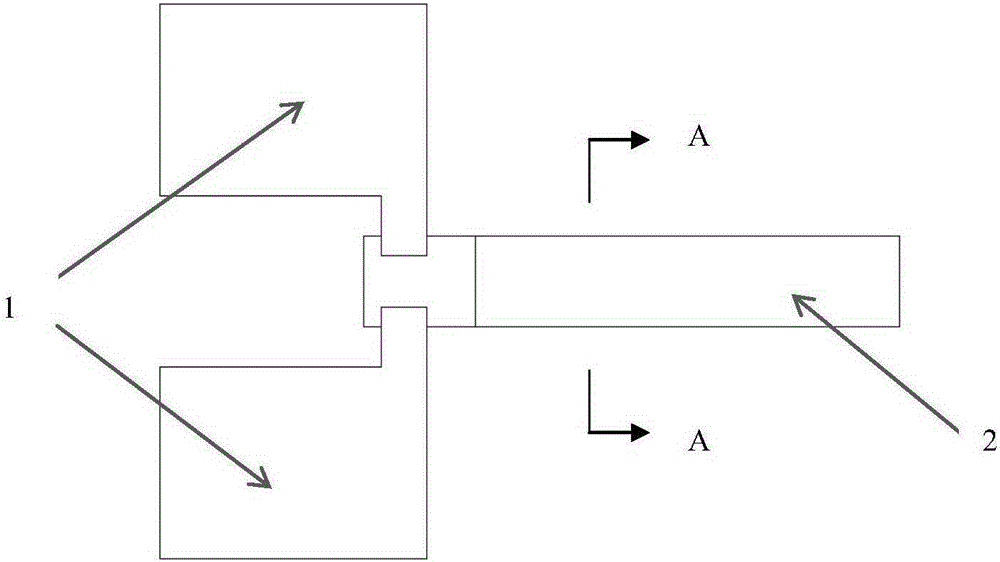

[0026] Such as figure 1 As shown, a MEMS electrothermal actuator of the present invention is a cantilever beam structure, the cantilever beam is composed of a pad 1 and a beam 2, the beam 2 has a fixed end and a cantilever end, and the pad 1 is located on both sides of the fixed end of the beam, which is The part that connects beam 2 with electricity. .

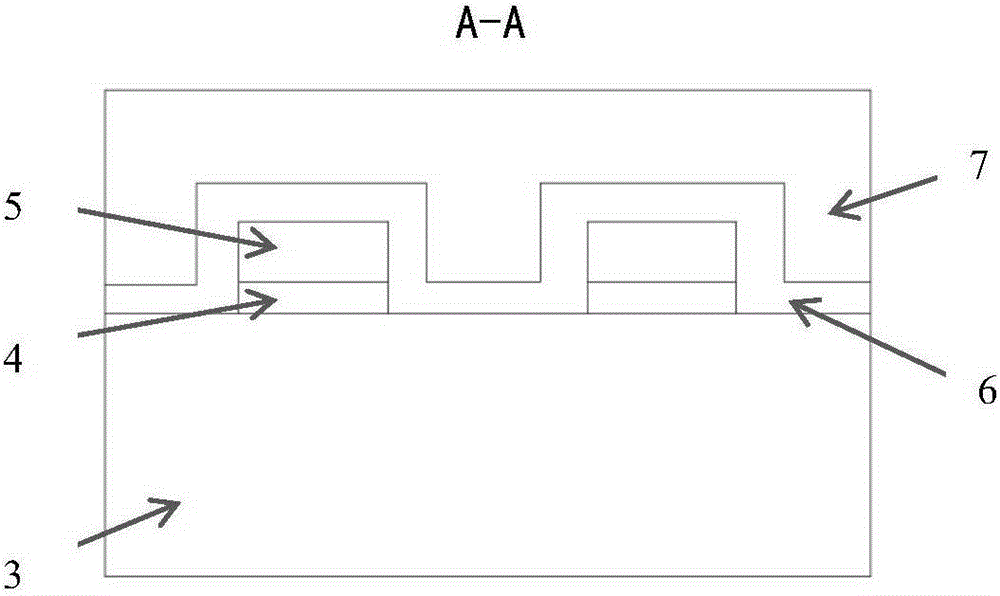

[0027] Such as figure 2 As shown, the beam 2 has a hierarchical structure. The beam 2 includes an upper layer 7, a middle layer 5, a lower layer 3, an adhesive layer 4 and an insulating layer 6. The thermal expansion coefficients of the upper layer material and the lower layer material are quite different. The difference in coefficients results in deformation of the beam 2, thus fulfilling the function of the actuator. The middle layer 5 is a heating layer, and the shapes of the middle layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal orientation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com