Welding device for socket pipe with plastic-wound structural wall and connecting technology thereof

The technology of structural wall pipe and structural wall is applied to the welding device and its connection process, and the connection field of plastic wound structural wall pipe and socket plug, which can solve the problems of cracking of the pipe system, incomplete use effect, water leakage, etc. Achieve consistent pressure strength, avoid cracking or water seepage, and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

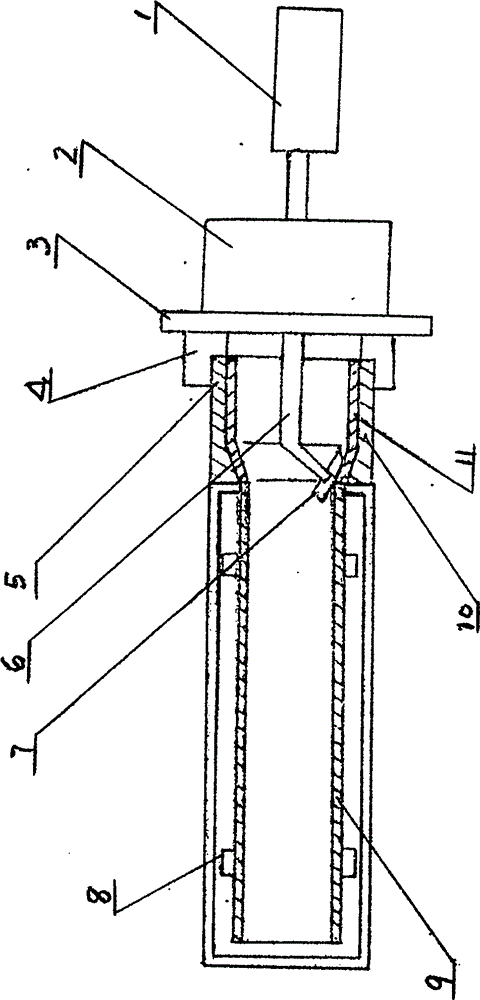

[0008] In conjunction with the accompanying drawings, use Pipe connection is taken as an example to further describe the present invention:

[0009] See attached figure 1 , the whole device is fixed on the support of the rotating mechanism 8, the inner cavity extruder 1 is arranged on the right track of the main shaft box 2, and the inner cavity extruder head 6 of the inner cavity extruder 1 passes through the head of the main shaft box 2 Spindle hole, the end of the extruder head 6 in the inner cavity is equipped with an inner scraper 7 that can move flexibly; the two outer jaws 4 on the upper side are fixed with the upper semicircular die 5, and the two outer jaws 4 on the lower side are fixed with the lower mold. The semicircular mold 10, the main shaft of the spindle box 2 is connected with the rotary chuck 3, and the rotary chuck 3 is evenly distributed with four claw grooves, and the outer claws 4 are respectively arranged in the claw grooves,

[0010] See attached f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com