High-silicon aluminum alloy welding method for forming particle-reinforced weld joints through thermo-acoustic coupling

A high-silicon aluminum alloy, particle-reinforced technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

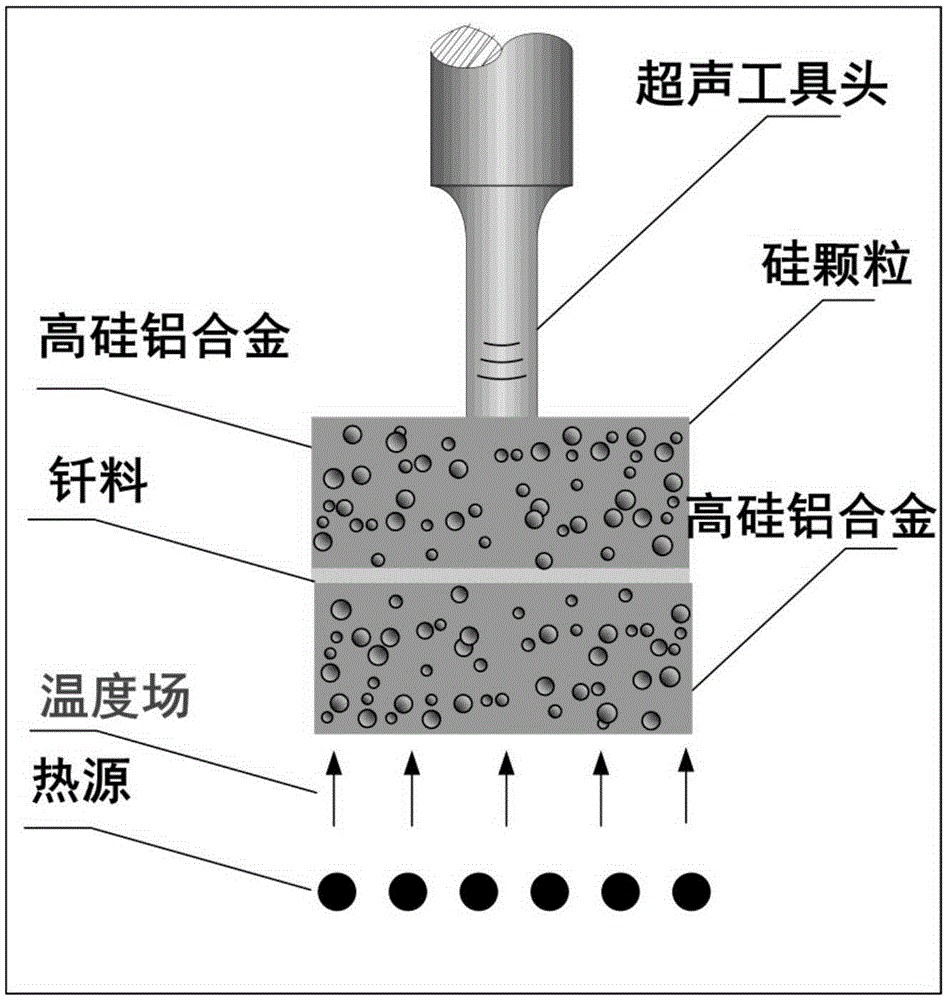

[0038] A welding method for high-silicon aluminum alloys that forms particle-reinforced welds through acoustic-thermal coupling control, using the coupling of ultrasonic waves and external heat sources to allow Si particles of the reinforcing phase in high-silicon aluminum alloys with a silicon mass content of 30% to enter the weld to form particles Enhanced composite weld structure, the steps are as follows:

[0039] 1. Before welding, use sandpaper to remove the oil impurities and oxide film on the surface of the solder Sn9Zn and the high-silicon aluminum alloy with a silicon mass content of 30% to be welded, then polish it, and then scrub the surface with acetone;

[0040] Two, step 1) obtains the high-silicon aluminum alloy and brazing filler metal to be welded silicon mass content 30% according to figure 1 Clamping in the manner shown;

[0041]3. Heat the high-silicon aluminum alloy to be welded and the brazing material clamped according to step 2) with an external heati...

Embodiment 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is: Step 1: Sn-xZn solder is changed to Zn-Al (x=0-50) solder, heated to a predetermined temperature of 330-470 ± 10 ° C, other steps Same as embodiment one;

Embodiment 3

[0044] Embodiment 3: The difference between this embodiment and one of Embodiments 1 to 2 is that the solder in step 1 is Sn-In, heated to a predetermined temperature of 70-270±10°C, and the others are the same as Embodiments 1 to 2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com