Rabbit breeding box and formation method thereof

A production box and rabbit technology, applied in the field of rabbit production box and its molding, can solve the problems that affect the normal delivery and lactation of female rabbits, the pups are easy to freeze to death, and the cost of manpower and materials is high, so as to improve growth and growth speed and health level, reduce the incidence of disease, increase the effect of reproductive number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The forming method of a kind of rabbit production box of the present invention, mainly realizes through the following steps:

[0017] A making foamed cement slurry,

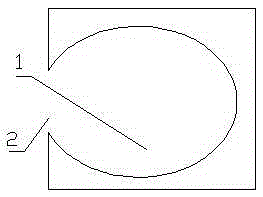

[0018] B. Pour the foamed cement slurry into a square or rectangular mold, prepare a balloon, inject water into the balloon, make the balloon increase to the size of the inner space of the rabbit production box to be made, and put the water-filled balloon into the foamed cement inside the slurry mold,

[0019] C Wait until the foamed cement slurry is solidified, demolded, and the balloon in the foamed cement is punctured to release the water in the balloon, and a space of the same size as the water-filled balloon will be vacated inside the production box made of foamed cement, and then it will be ready after maintenance. become.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com