Method for controlling a hydrodynamic retarder that can be mechanically disengaged by a disconnect clutch

A separation clutch and hydraulic reducer technology, applied in the field of hydraulic reducer, can solve the problems of shortened service life and high separation clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

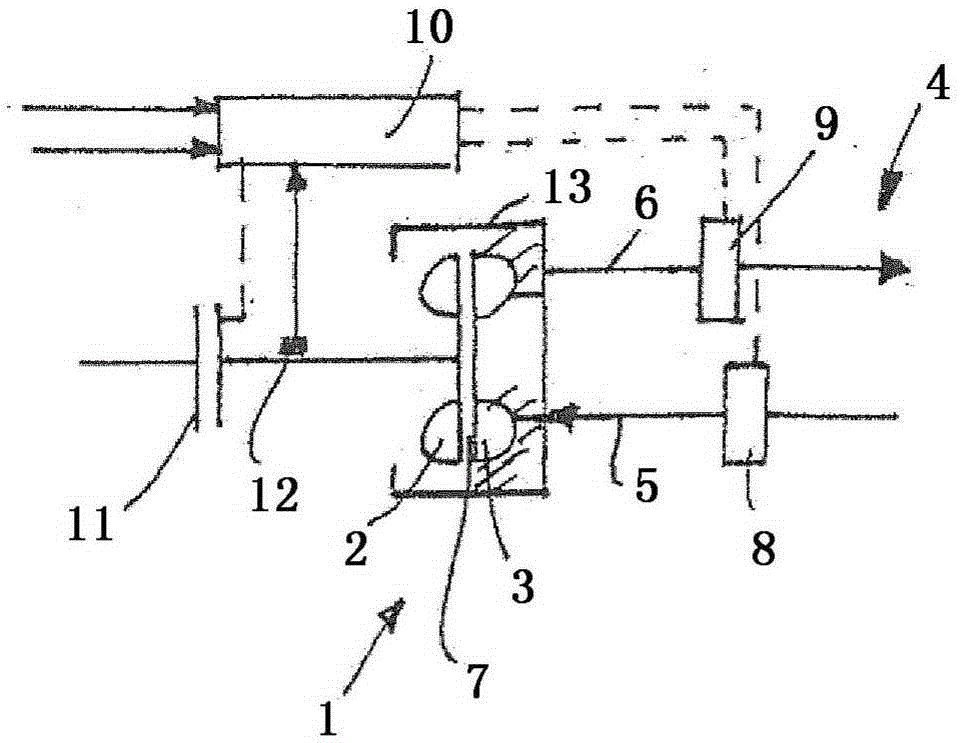

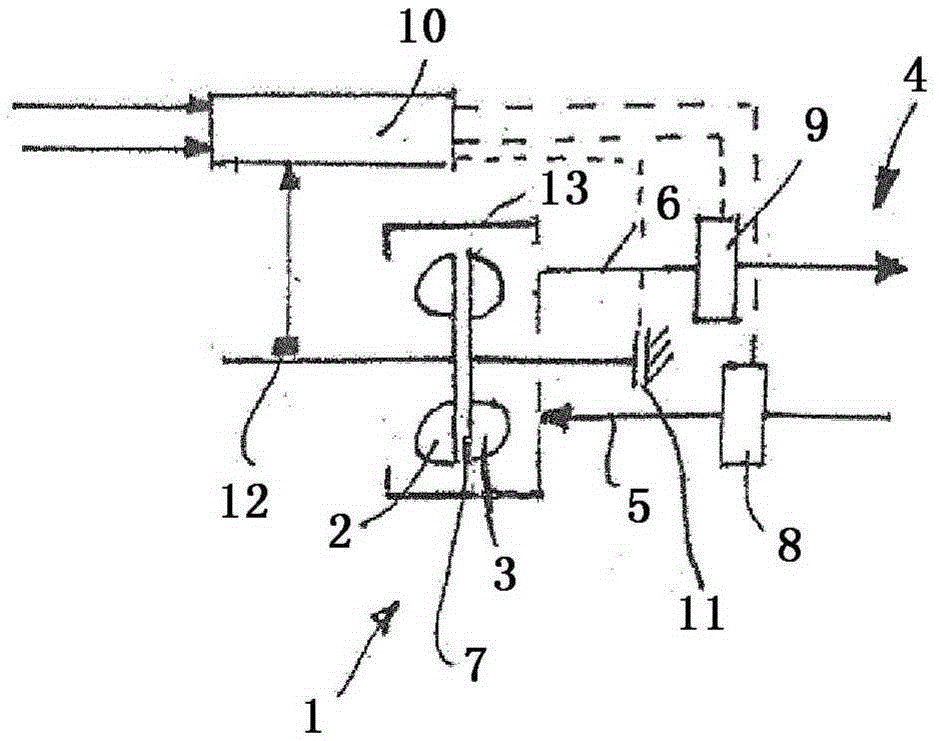

[0032] exist figure 1 A hydrodynamic retarder 1 with a rotor 2 and a stator 3 is shown in . Working medium is fed from the external working medium circuit 4 via the working medium supply 5 to the working chamber 7 and is discharged from the gear unit 1 via the working medium discharge 6 for cooling the working medium heated in the working chamber 7 . An inlet valve 8 is arranged in the working medium supply 5 , and a retarder outlet valve 9 is arranged in the working medium outlet 6 . The retarder control device 10 acts at least indirectly both on the retarder inlet valve 8 and also on the retarder outlet valve 9 . For the transition from non-braking operation to braking operation, the retarder inlet valve 8 is opened. The retarder outlet valve 9 is actuated with the set pressure such that it leads to the desired retention of the working medium and thus to the desired filling degree of the working chamber 7 . Alternatively, it is also conceivable to control the degree of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com