Row insensitive plant harvesting system

A technology of plants and receiving tanks, applied in the direction of harvesters, agricultural machinery and implements, applications, etc., can solve problems such as not being very good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

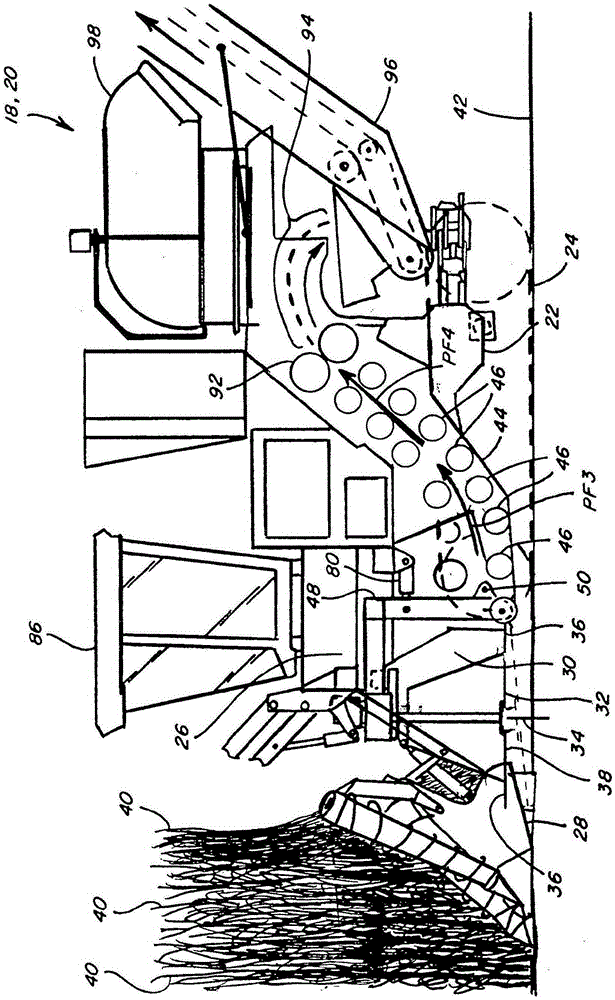

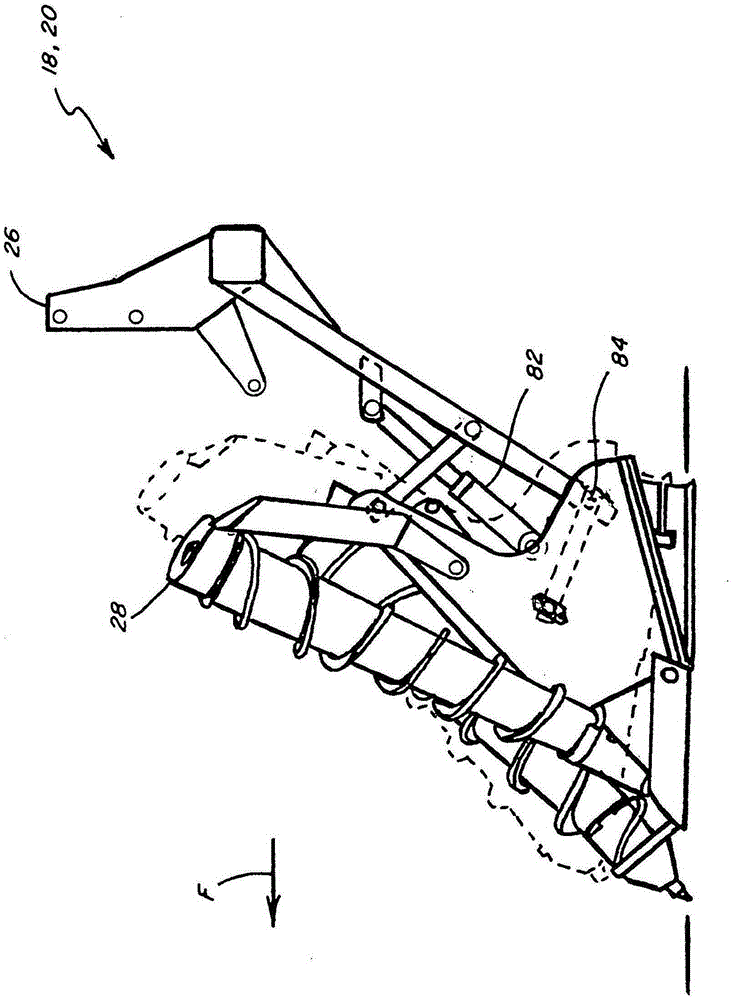

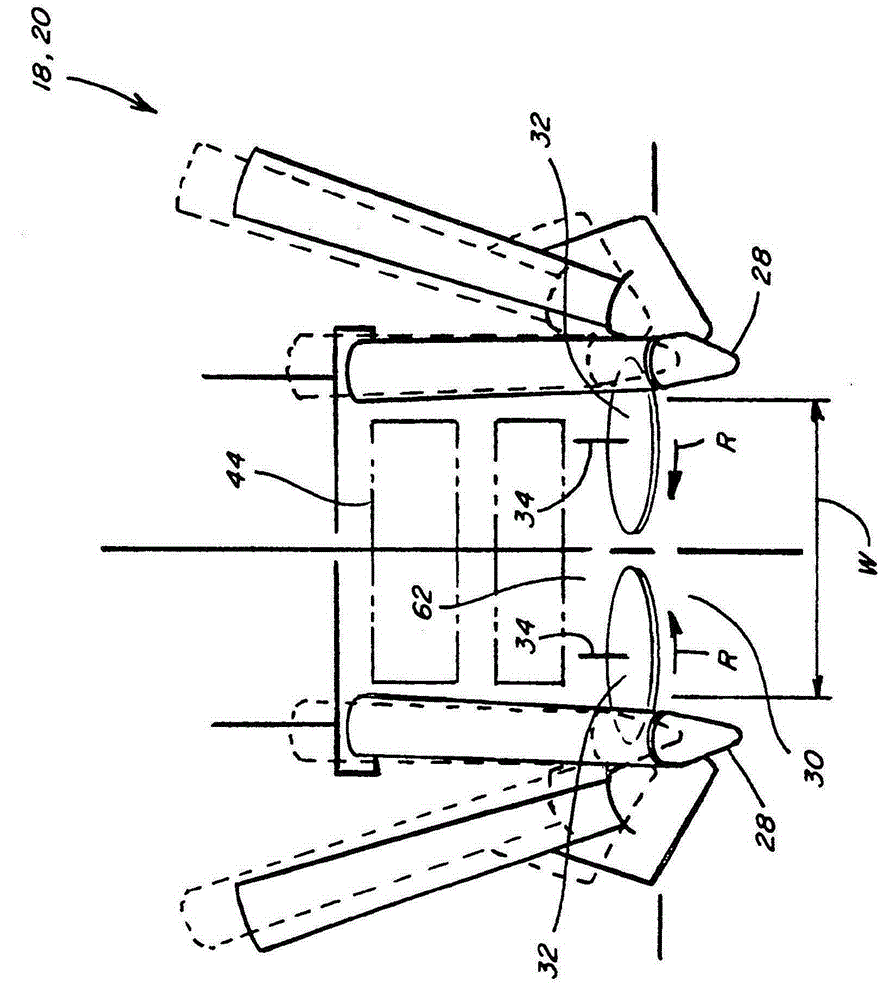

[0033] Referring to the accompanying drawings below, in figure 1 A row-independent harvesting system 20 of the present invention is shown in , suitable for high volume harvesting of taller stemmed plants, such as sugar cane, milo, etc., while maintaining the integrity of the cut plants for water conservation purposes until further processing , such as strip cutting. Generally, the illustrated harvester 18 is of the self-propelled type and includes a frame 22 supported on wheels or tracks 24 for movement on the ground, the frame 22 including a front end 26 supporting: a forwardly extending plant divider 28 defining and defining a forwardly open front end; a rearwardly extending plant receiving channel 30; and a pair of side-by-side rotating base cutters 32 which 32 are carried on the frame 22 and within the plant receiving channel 30 for rotation about a generally vertical axis of rotation 34 of the base cutters 32, respectively. Each base cutter 32 carries a blade 36 on its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com